- Electric and Telecom Plans Free

- Fire and Emergency Plans Free

- Floor Plans Free

- Plant Layout Plans Free

- School and Training Plans Free

- Seating Plans Free

- Security and Access Plans Free

- Site Plans Free

- Sport Field Plans Free

- Business Process Diagrams Free

- Business Process Mapping Free

- Classic Business Process Modeling Free

- Cross-Functional Flowcharts Free

- Event-driven Process Chain Diagrams Free

- IDEF Business Process Diagrams Free

- Logistics Flow Charts Free

- Workflow Diagrams Free

- ConceptDraw Dashboard for Facebook Free

- Mind Map Exchange Free

- MindTweet Free

- Note Exchange Free

- Project Exchange Free

- Social Media Response Free

- Active Directory Diagrams Free

- AWS Architecture Diagrams Free

- Azure Architecture Free

- Cisco Network Diagrams Free

- Cisco Networking Free

- Cloud Computing Diagrams Free

- Computer Network Diagrams Free

- Google Cloud Platform Free

- Interactive Voice Response Diagrams Free

- Network Layout Floor Plans Free

- Network Security Diagrams Free

- Rack Diagrams Free

- Telecommunication Network Diagrams Free

- Vehicular Networking Free

- Wireless Networks Free

- Comparison Dashboard Free

- Composition Dashboard Free

- Correlation Dashboard Free

- Frequency Distribution Dashboard Free

- Meter Dashboard Free

- Spatial Dashboard Free

- Status Dashboard Free

- Time Series Dashboard Free

- Basic Circle-Spoke Diagrams Free

- Basic Circular Arrows Diagrams Free

- Basic Venn Diagrams Free

- Block Diagrams Free

- Concept Maps Free

- Family Tree Free

- Flowcharts Free

- Basic Area Charts Free

- Basic Bar Graphs Free

- Basic Divided Bar Diagrams Free

- Basic Histograms Free

- Basic Line Graphs Free

- Basic Picture Graphs Free

- Basic Pie Charts Free

- Basic Scatter Diagrams Free

- Aerospace and Transport Free

- Artwork Free

- Audio, Video, Media Free

- Business and Finance Free

- Computers and Communications Free

- Holiday Free

- Manufacturing and Maintenance Free

- Nature Free

- People Free

- Presentation Clipart Free

- Safety and Security Free

- Analog Electronics Free

- Audio and Video Connectors Free

- Basic Circuit Diagrams Free

- Chemical and Process Engineering Free

- Digital Electronics Free

- Electrical Engineering Free

- Electron Tube Circuits Free

- Electronic Block Diagrams Free

- Fault Tree Analysis Diagrams Free

- GHS Hazard Pictograms Free

- Home Automation and Wiring Free

- Mechanical Engineering Free

- One-line Diagrams Free

- Power Сircuits Free

- Specification and Description Language (SDL) Free

- Telecom and AV Circuits Free

- Transport Hazard Pictograms Free

- Data-driven Infographics Free

- Pictorial Infographics Free

- Spatial Infographics Free

- Typography Infographics Free

- Calendars Free

- Decision Making Free

- Enterprise Architecture Diagrams Free

- Fishbone Diagrams Free

- Organizational Charts Free

- Plan-Do-Check-Act (PDCA) Free

- Seven Management and Planning Tools Free

- SWOT and TOWS Matrix Diagrams Free

- Timeline Diagrams Free

- Australia Map Free

- Continent Maps Free

- Directional Maps Free

- Germany Map Free

- Metro Map Free

- UK Map Free

- USA Maps Free

- Customer Journey Mapping Free

- Marketing Diagrams Free

- Matrices Free

- Pyramid Diagrams Free

- Sales Dashboard Free

- Sales Flowcharts Free

- Target and Circular Diagrams Free

- Cash Flow Reports Free

- Current Activities Reports Free

- Custom Excel Report Free

- Knowledge Reports Free

- MINDMAP Reports Free

- Overview Reports Free

- PM Agile Free

- PM Dashboards Free

- PM Docs Free

- PM Easy Free

- PM Meetings Free

- PM Planning Free

- PM Presentations Free

- PM Response Free

- Resource Usage Reports Free

- Visual Reports Free

- House of Quality Free

- Quality Mind Map Free

- Total Quality Management TQM Diagrams Free

- Value Stream Mapping Free

- Astronomy Free

- Biology Free

- Chemistry Free

- Language Learning Free

- Mathematics Free

- Physics Free

- Piano Sheet Music Free

- Android User Interface Free

- Class Hierarchy Tree Free

- Data Flow Diagrams (DFD) Free

- DOM Tree Free

- Entity-Relationship Diagram (ERD) Free

- EXPRESS-G data Modeling Diagram Free

- IDEF0 Diagrams Free

- iPhone User Interface Free

- Jackson Structured Programming (JSP) Diagrams Free

- macOS User Interface Free

- Object-Role Modeling (ORM) Diagrams Free

- Rapid UML Free

- SYSML Free

- Website Wireframe Free

- Windows 10 User Interface Free

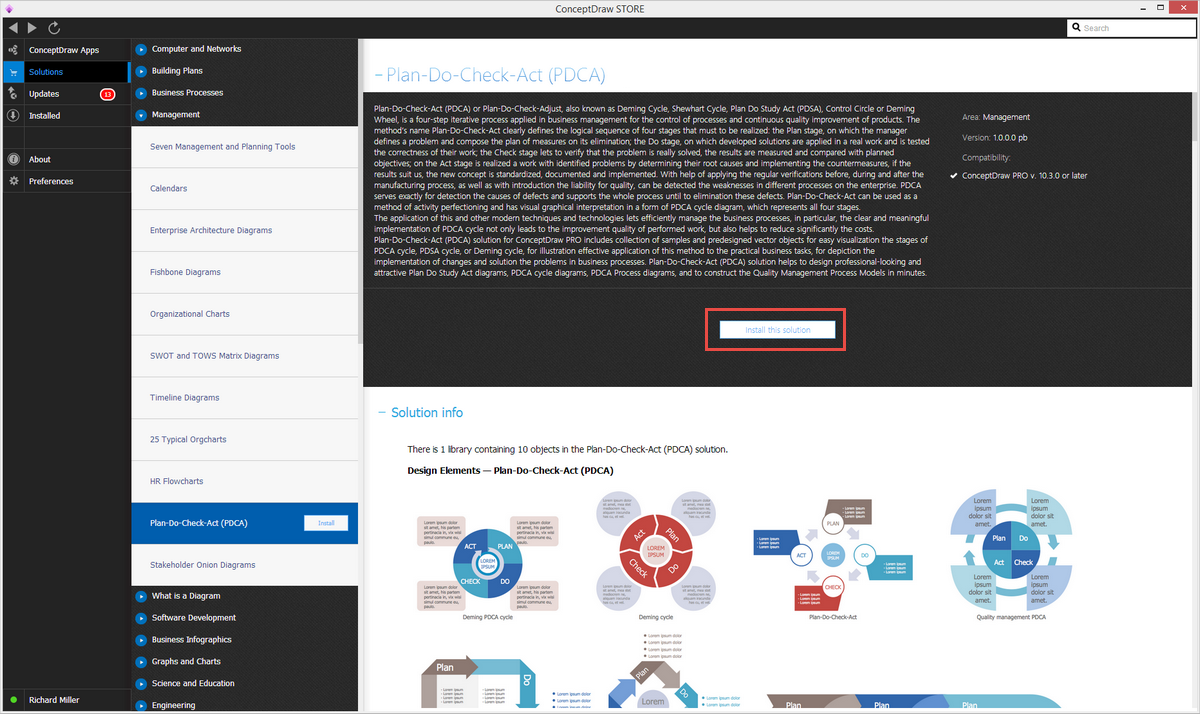

Plan-Do-Check-Act (PDCA)

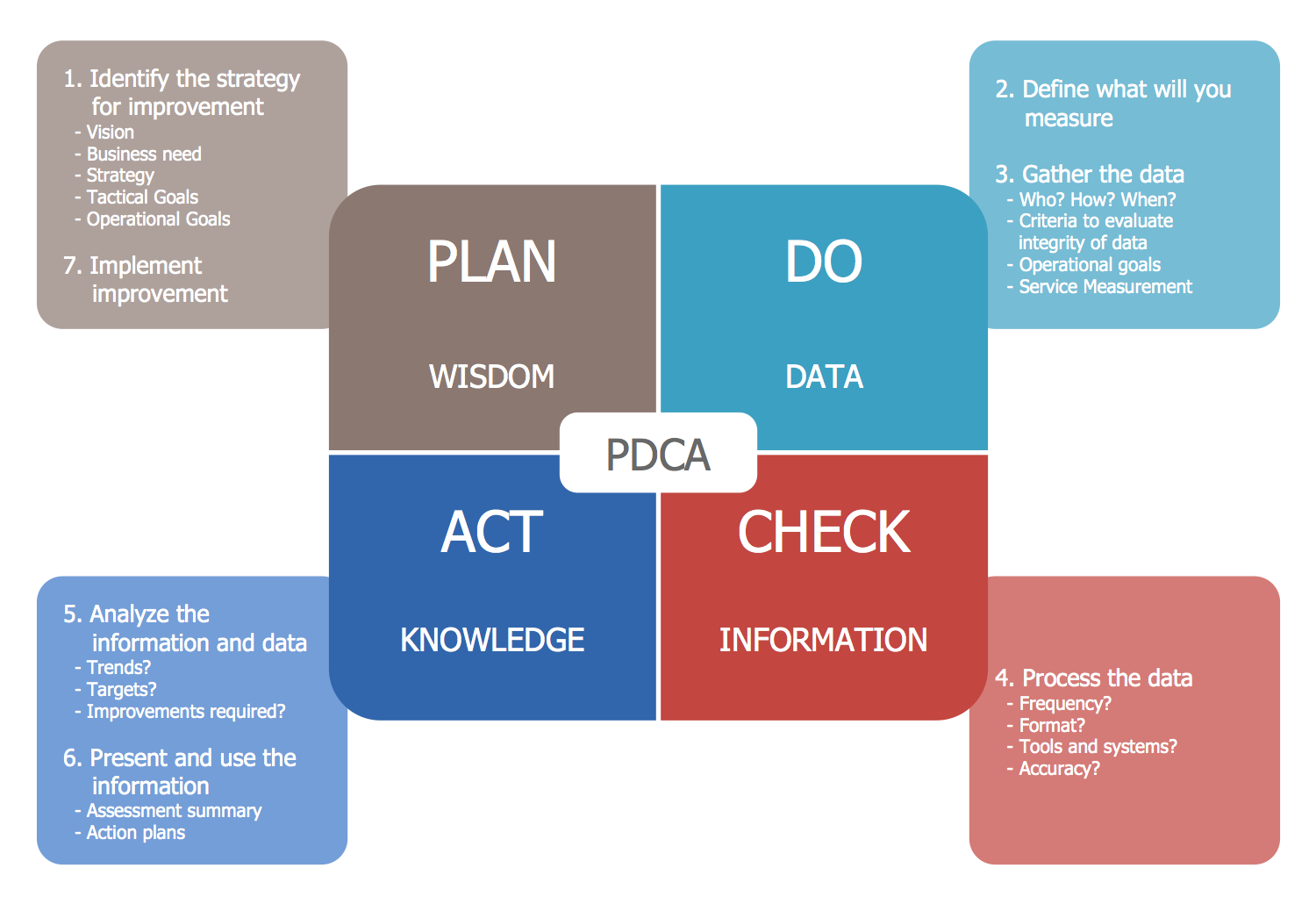

Plan-Do-Check-Act (PDCA) or Plan-Do-Check-Adjust, also known as Deming Cycle, Shewhart Cycle, Plan Do Study Act (PDSA), Control Circle or Deming Wheel, is a four-step iterative process applied in business management for the control of processes and continuous quality improvement of products. The method's name Plan-Do-Check-Act clearly defines the logical sequence of four stages that must to be realized: the Plan stage, on which the manager defines a problem and compose the plan of measures on its elimination; the Do stage, on which developed solutions are applied in a real work and is tested the correctness of their work; the Check stage lets to verify that the problem is really solved, the results are measured and compared with planned objectives; on the Act stage is realized a work with identified problems by determining their root causes and implementing the countermeasures, if the results suit us, the new concept is standardized, documented and implemented. With help of applying the regular verifications before, during and after the manufacturing process, as well as with introduction the liability for quality, can be detected the weaknesses in different processes on the enterprise. PDCA serves exactly for detection the causes of defects and supports the whole process until to elimination these defects. Plan-Do-Check-Act can be used as a method of activity perfectioning and has visual graphical interpretation in a form of PDCA cycle diagram, which represents all four stages.

The application of this and other modern techniques and technologies lets efficiently manage the business processes, in particular, the clear and meaningful implementation of PDCA cycle not only leads to the improvement quality of performed work, but also helps to reduce significantly the costs.

Plan-Do-Check-Act (PDCA) solution for ConceptDraw DIAGRAM includes collection of samples and predesigned vector objects for easy visualization the stages of PDCA cycle, PDSA cycle, or Deming cycle, for illustration effective application of this method to the practical business tasks, for depiction the implementation of changes and solution the problems in business processes. Plan-Do-Check-Act (PDCA) solution helps to design professional-looking and attractive Plan Do Study Act diagrams, PDCA cycle diagrams, PDCA Process diagrams, and to construct the Quality Management Process Models in minutes.

-

Install this solution Free -

What I need to get started -

Solution Requirements - This solution requires the following products to be installed:

ConceptDraw DIAGRAM v18 - This solution requires the following products to be installed:

-

Compatibility - Sonoma (14), Sonoma (15)

MS Windows 10, 11 - Sonoma (14), Sonoma (15)

-

Support for this Solution -

Helpdesk

There is 1 library containing 10 objects in the Plan-Do-Check-Act (PDCA) solution.

Design Elements — Plan-Do-Check-Act (PDCA)

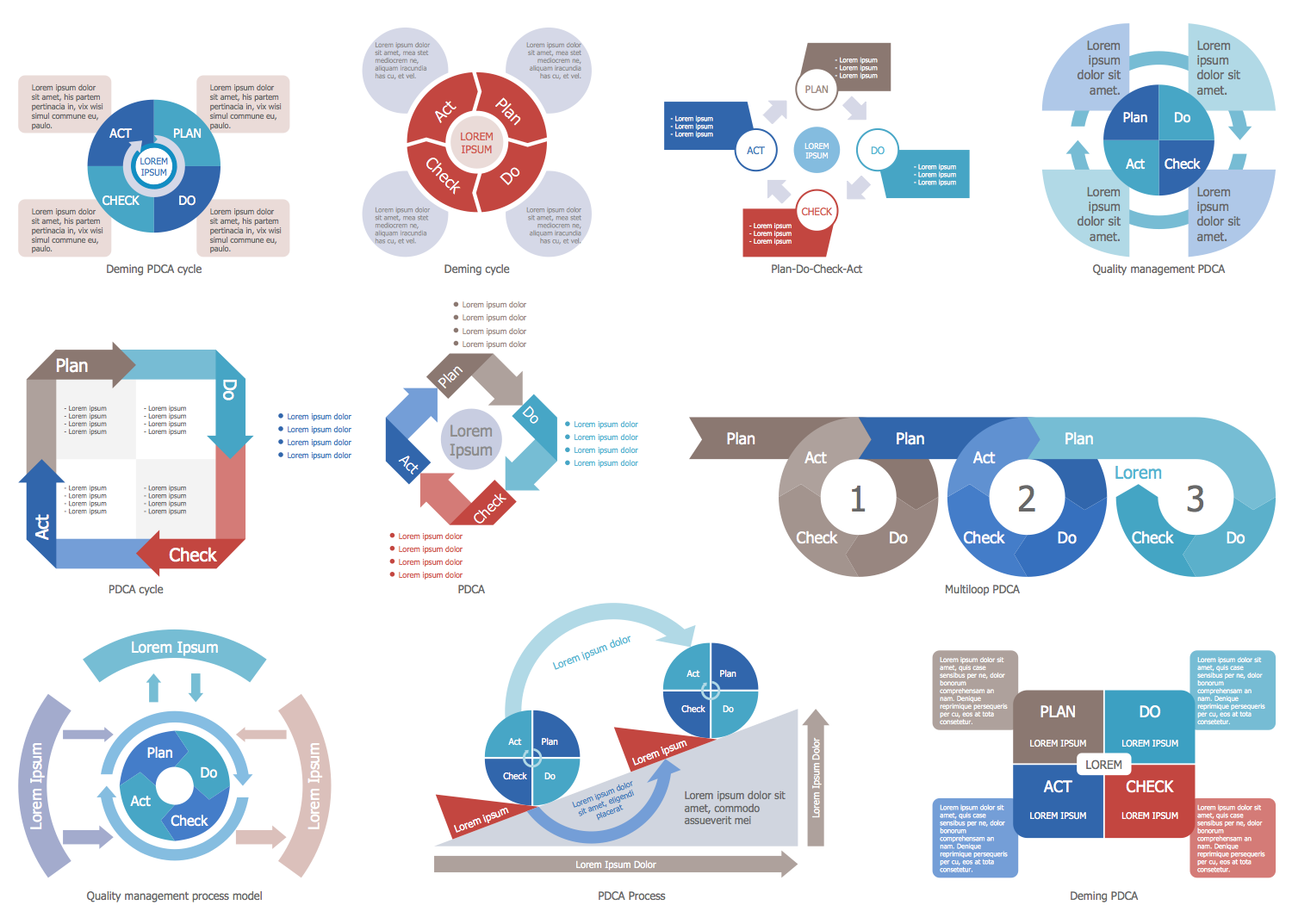

Plan-Do-Check-Act (PDCA) Examples

There are a few samples that you see on this page which were created in the ConceptDraw DIAGRAM application by using the Plan-Do-Check-Act (PDCA) solution. Some of the solution's capabilities as well as the professional results which you can achieve are all demonstrated here on this page.

All source documents are vector graphic documents which are always available for modifying, reviewing and/or converting to many different formats, such as MS PowerPoint, PDF file, MS Visio, and many other graphic ones from the ConceptDraw Solution Park or ConceptDraw STORE. The Plan-Do-Check-Act (PDCA) solution is available to all ConceptDraw DIAGRAM users to get installed and used while working in the ConceptDraw DIAGRAM diagramming and drawing software.

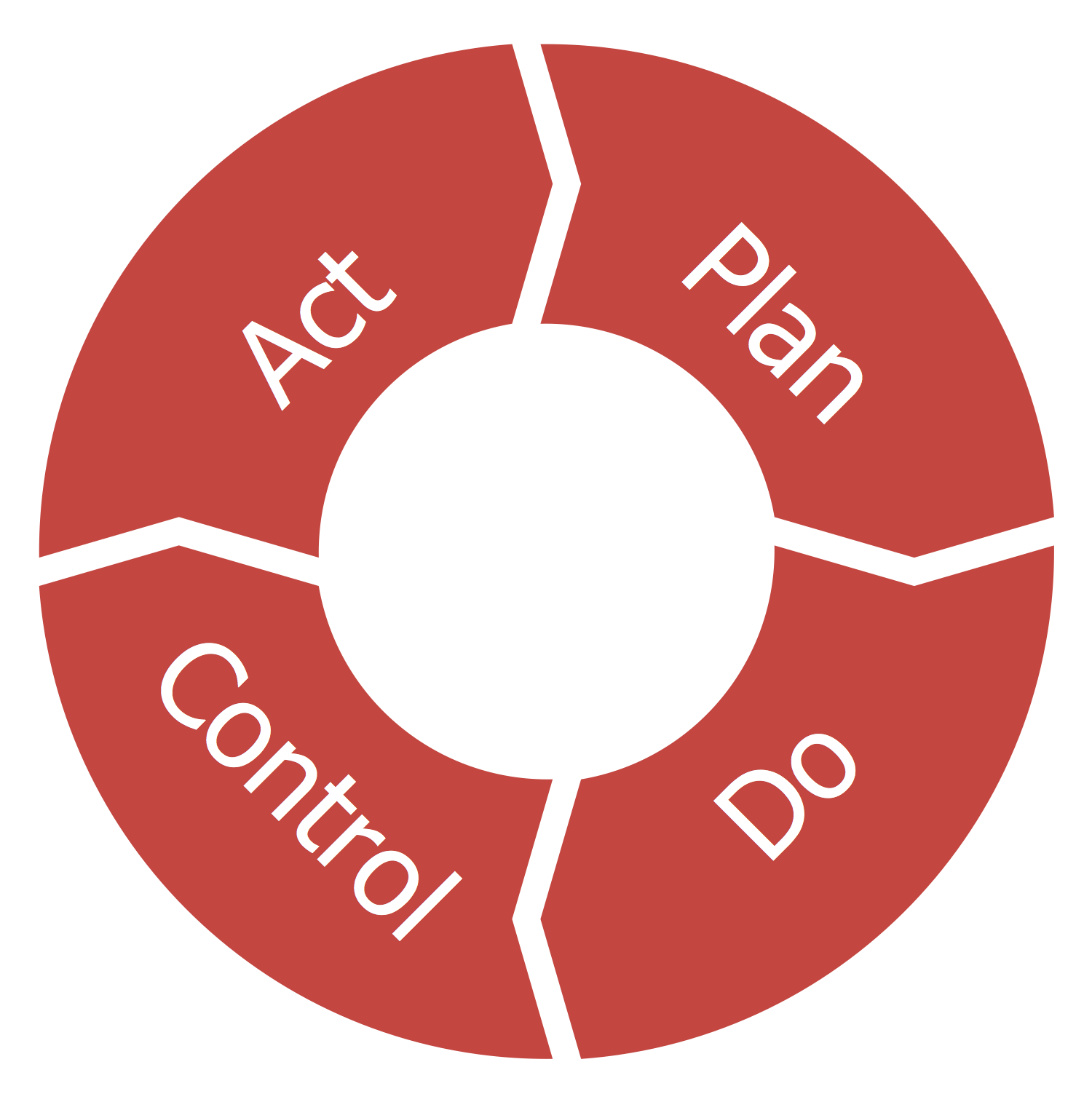

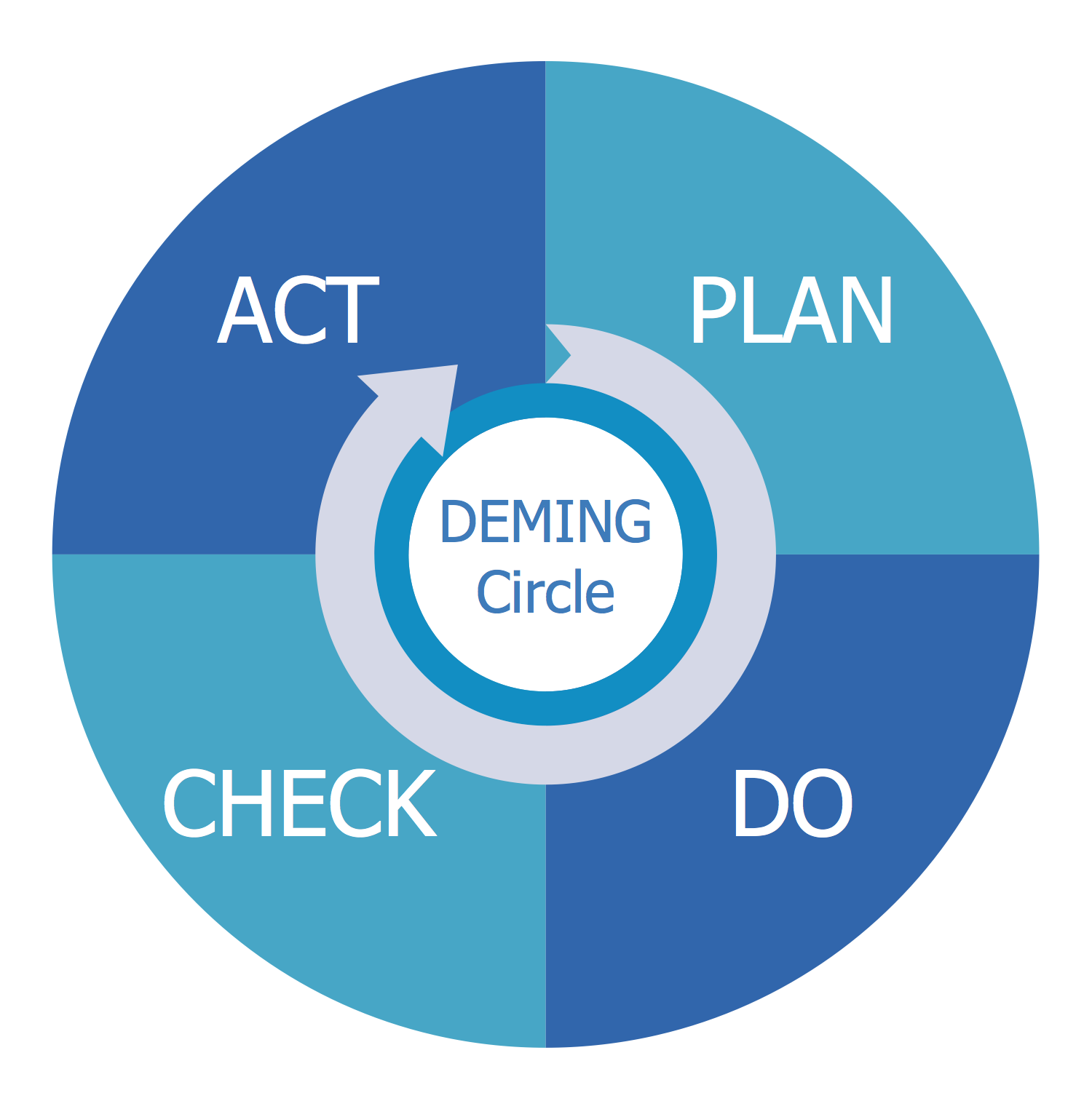

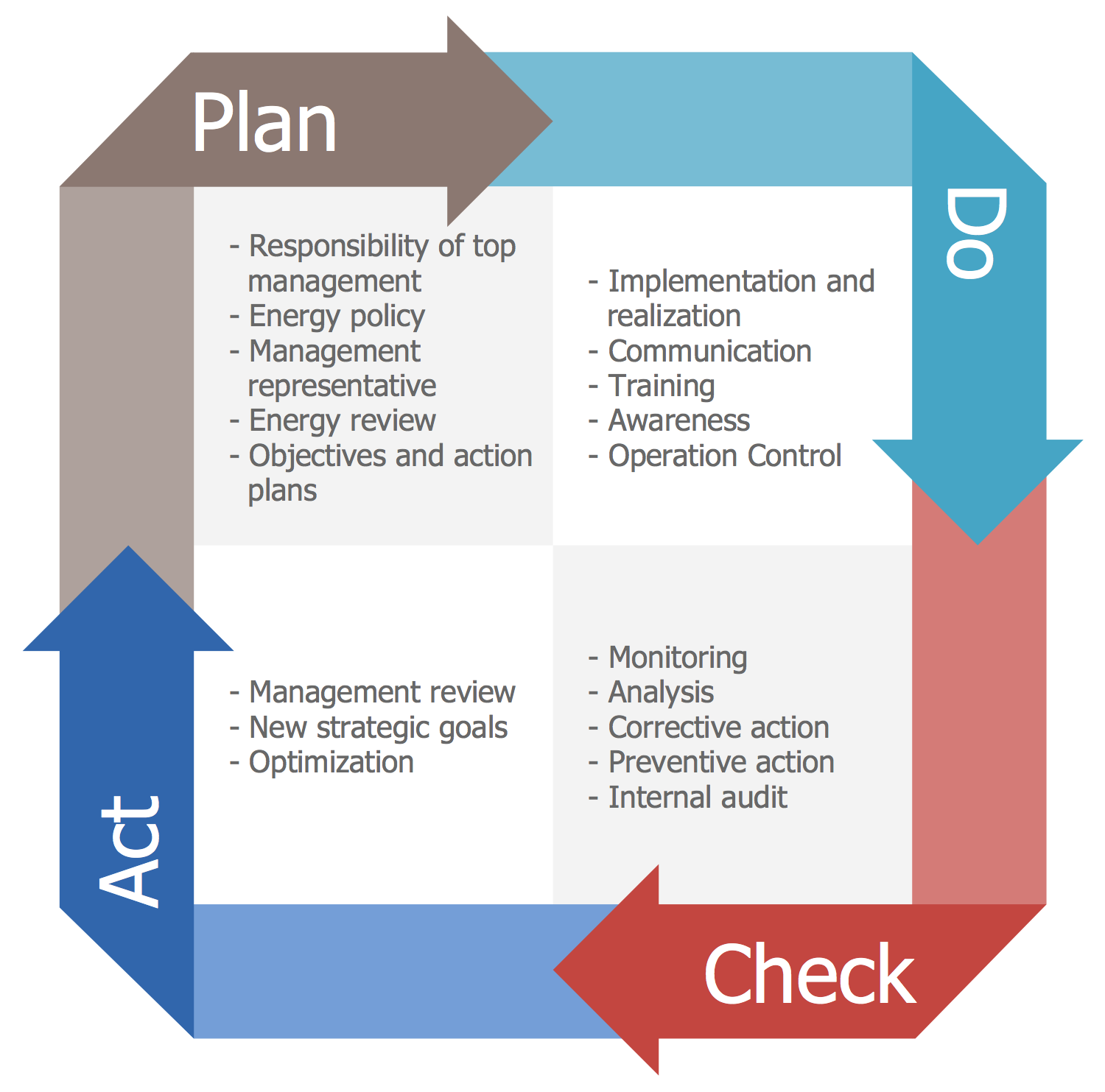

Example 1: Deming Cycle

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 2 minutes creating this sample.

This sample shows the Deming Cycle, which is a model that offers the plan of step-by-step problem solving and continuous improvement. The Deming cycle contains four phases: Plan, Do, Control, Act. In practice, the PDCA cycle is applied repeatedly with varied periodicity. In carrying out the basic activities the PDCA cycle is applied with periodicity of reporting and planning cycles, in the case of corrective actions its duration may be less or more than duration of the reporting and planning cycles.

Example 2: Deming PDCA

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

This Deming PDCA sample illustrates the continuous improvement. It represents a logical sequence of four steps, which are aimed at continuous enhancement and learning: Plan, Do, Check and Act. Each step contains defined actions for step-by-step execution, that are described in details on this sample. It is easy to notice a not quite standard form of PDCA diagram, that significantly helped to make it the most informative.

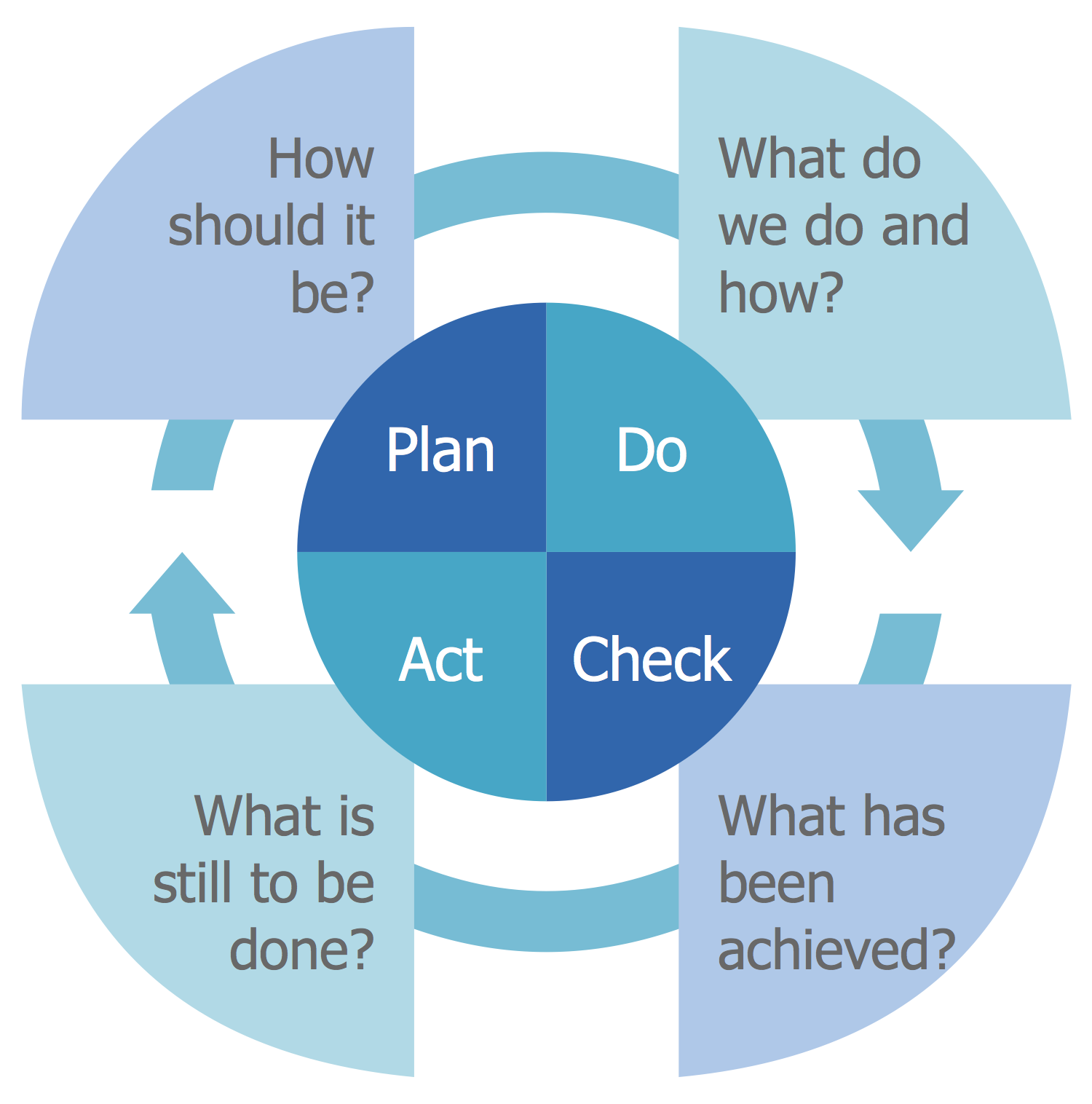

Example 3: Deming PDCA Cycle

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 2 minutes creating this sample.

This example represents the Deming or Plan-Do-Check-Act (PDCA) Cycle diagram, also known as a Shewart cycle according to the name of first creator of this method. Slightly changed by Dr W. Edwards Deming, this method remains the de-facto standard for project management processes along the many years.

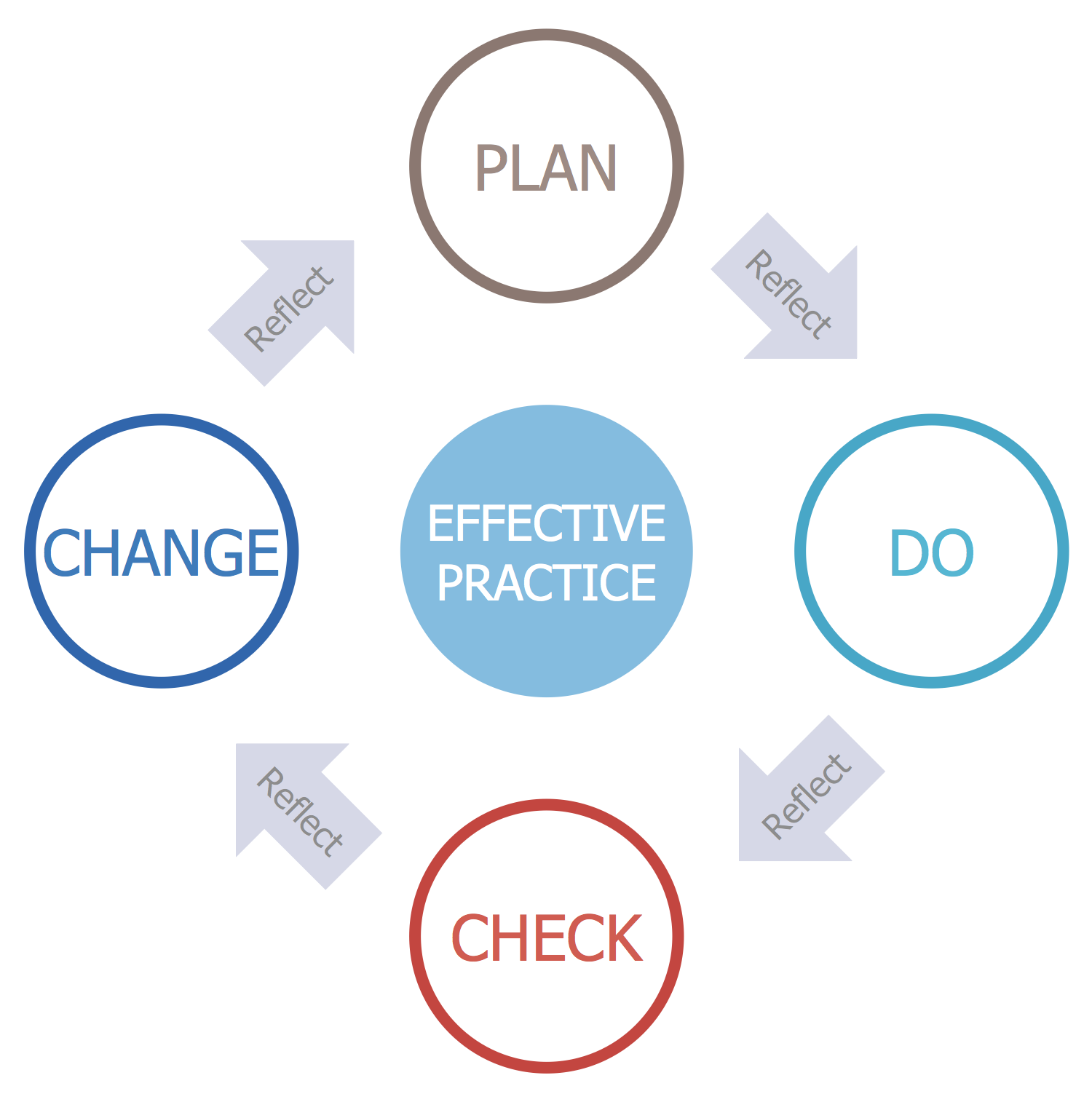

Example 4: Effective Practice PDCA

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 2 minutes creating this sample.

This sample illustrates effective practice of PDCA, the first step of which is to compose the plan of actions (Plan), the second step supposes their implementation (Do) according with a plan. After these two steps follow not less important steps: you need to measure and learn (Check) the received results and improvements, and then carry the actions (Change) in direction of adaptation the goals and improvements. Do not afraid to experiment with colors for amelioration a visual effect.

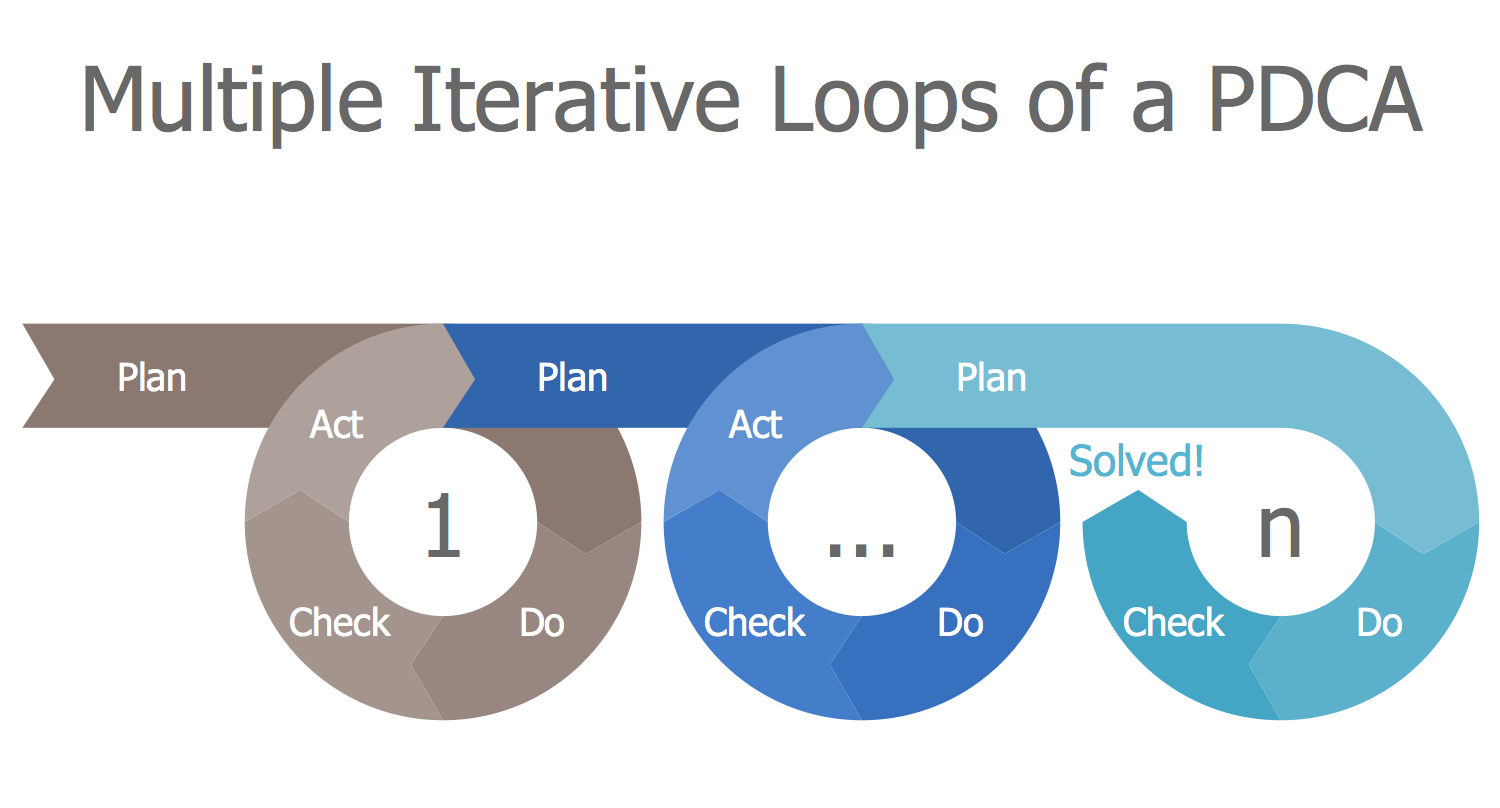

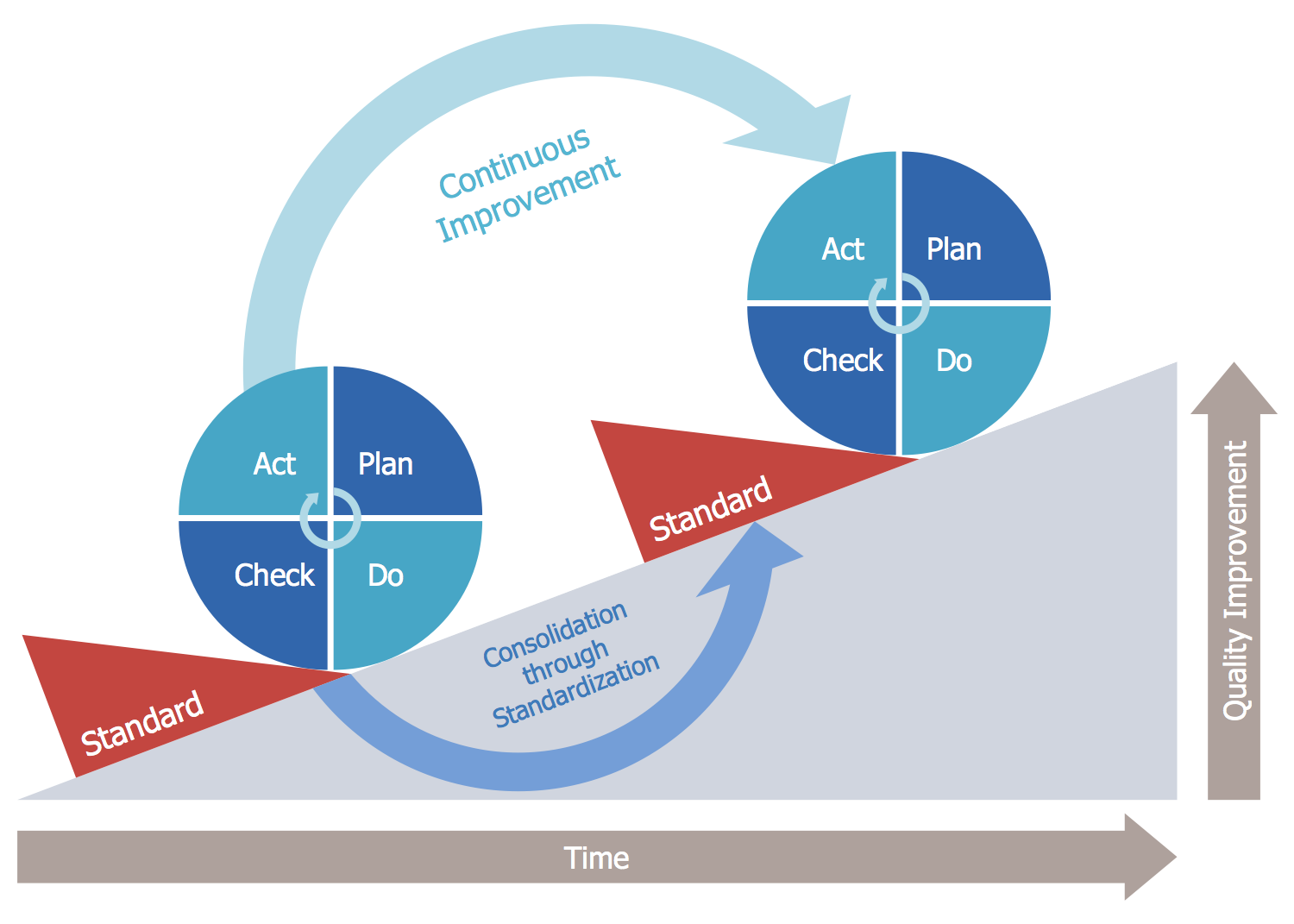

Example 5: Multiloop PDCA

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 2 minutes creating this sample.

The iteration is a fundamental principle of PDCA method, which brings us nearer to the goal. As soon as some hypothesis is confirmed or negated, the repetitive execution of the loop will expand more our knowledge about the studied system. This sample illustrates multiple iterative loops of a PDCA. Each of these loops contains the Plan, Do, Check, and Act steps, the loops are repeated until the problem will be solved.

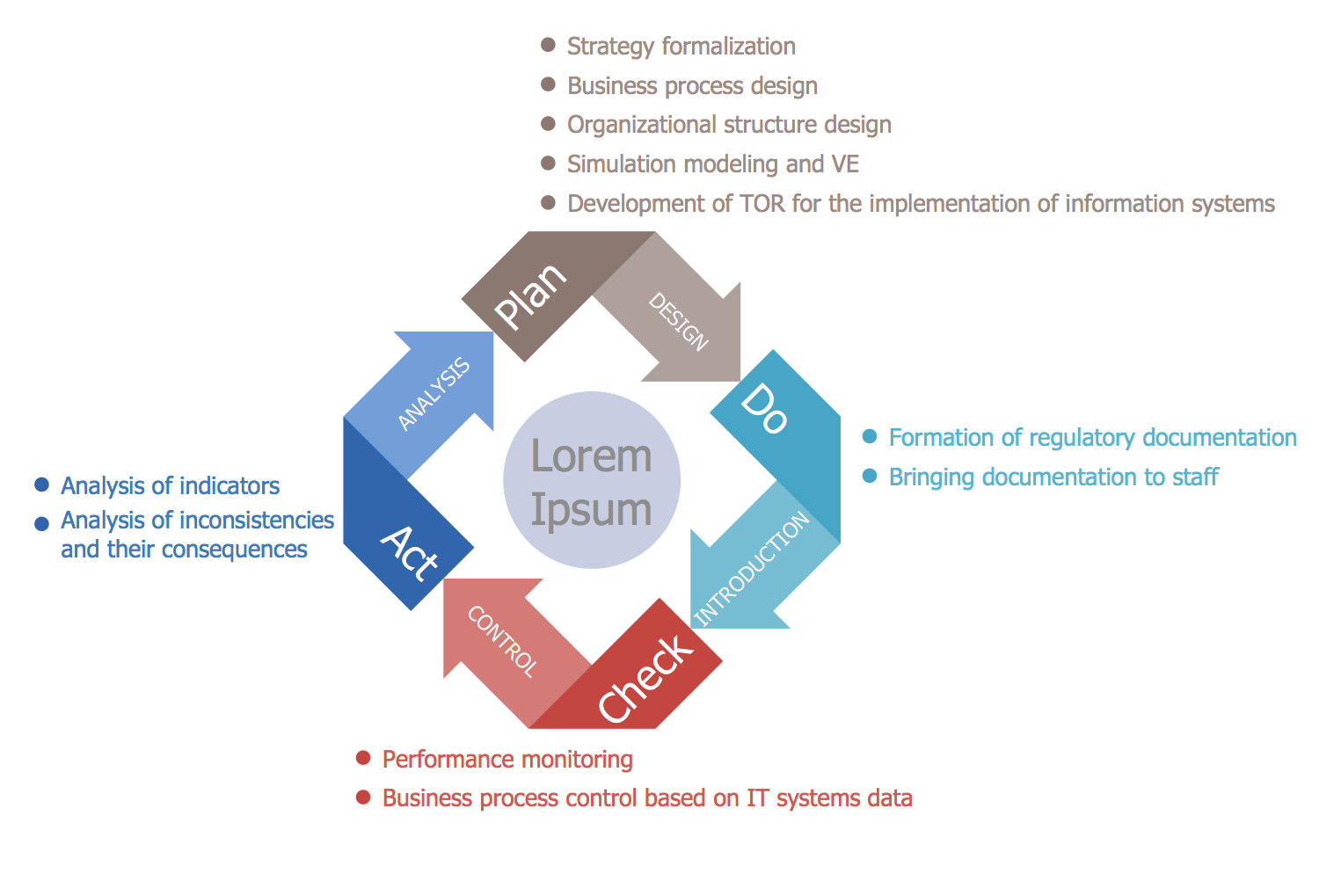

Example 6: PDCA

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

This PDCA sample diagram is dedicated to the Business Studio software. The methodic of its development, introduction, use and support is presented by the full PDCA cycle. This diagram is incredibly detailed and describes all functional abilities of software product that is perfect in projects of business reorganization, optimization and reglamentation, introduction and certification of Quality Management System (QMS), introduction of complex information systems (ERP, CRM, ECM, etc.). A variety of ready-to-use PDCA objects offered by ConceptDraw’s Plan-Do-Check-Act (PDCA) solution lets to choose required for your needs and use it as a quick-start template.

Example 7: PDCA Cycle

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

This sample describes four phases of PDCA cycle based on the specification ISO 50001 «Energy management systems – Requirements with guidance for use», which was developed for management by the energy systems and defines requirements for installation, implementation, maintenance and improvement the system of energy management. The best idea of coloring variously the PDCA steps serves for additional visual division of information.

Example 8: PDCA Process

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

This example depicts in professional and vivid way the PDCA process that is described by four steps in a wheel format, and ensures that the business continuity system can be reviewed and improved to be compliant with ISO standards. The continuous quality improvement is attained by the way of iterating through the cycle and by consolidating the achieved progress via the standardization.

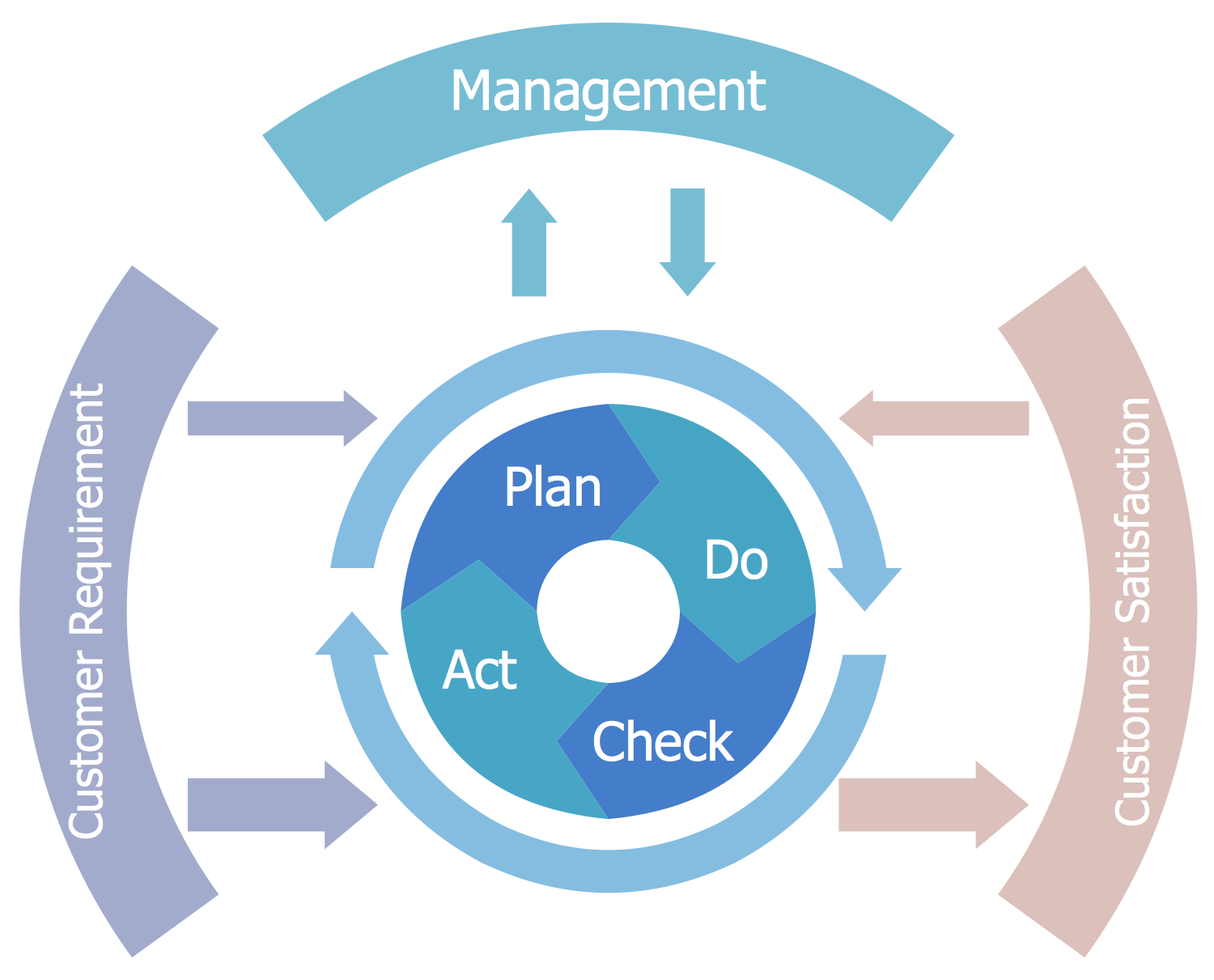

Example 9: Quality Management PDCA

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

PDCA (Plan-Do-Check-Act) method is widely used in project management and quality management as a method of continuous enhancement quality. It serves for effective detection the weaknesses in different processes on the enterprise and for support of the whole process up to the elimination the defects. This stylish sample illustrates the Quality Management PDCA circle with labels.

Example 10: Quality Management Process Model

This example was created in ConceptDraw DIAGRAM using the Plan-Do-Check-Act (PDCA) library from the Plan-Do-Check-Act (PDCA) Solution. An experienced user spent 5 minutes creating this sample.

The quality management is a complex of methodologies, processes and resources, which let to ensure the consistent quality of some product or service, that lets to enhance the competitiveness of it and of the whole organization on the market. This sample represents the Quality Management Process Model that is a closed loop system and includes the PDCA circle.

Inside

What I Need to Get Started

Both ConceptDraw DIAGRAM diagramming and drawing software and the Plan-Do-Check-Act (PDCA) solution can help creating the business planning diagrams you need. The Plan-Do-Check-Act (PDCA) solution can be found in the Management area of ConceptDraw STORE application that can be downloaded from this site. Make sure that both ConceptDraw DIAGRAM and ConceptDraw STORE applications are installed on your computer before you get started.

How to install

After ConceptDraw STORE and ConceptDraw DIAGRAM are downloaded and installed, you can install the Plan-Do-Check-Act (PDCA) solution from the ConceptDraw STORE.

Start using

To make sure that you are doing it all right, use the pre-designed symbols from the stencil libraries from the solution to make your drawings look smart and professional. Also, the pre-made examples from this solution can be used as drafts so your own drawings can be based on them. Using the samples, you can always change their structures, colors and data.