- Electric and Telecom Plans Free

- Fire and Emergency Plans Free

- Floor Plans Free

- Plant Layout Plans Free

- School and Training Plans Free

- Seating Plans Free

- Security and Access Plans Free

- Site Plans Free

- Sport Field Plans Free

- Business Process Diagrams Free

- Business Process Mapping Free

- Classic Business Process Modeling Free

- Cross-Functional Flowcharts Free

- Event-driven Process Chain Diagrams Free

- IDEF Business Process Diagrams Free

- Logistics Flow Charts Free

- Workflow Diagrams Free

- ConceptDraw Dashboard for Facebook Free

- Mind Map Exchange Free

- MindTweet Free

- Note Exchange Free

- Project Exchange Free

- Social Media Response Free

- Active Directory Diagrams Free

- AWS Architecture Diagrams Free

- Azure Architecture Free

- Cisco Network Diagrams Free

- Cisco Networking Free

- Cloud Computing Diagrams Free

- Computer Network Diagrams Free

- Google Cloud Platform Free

- Interactive Voice Response Diagrams Free

- Network Layout Floor Plans Free

- Network Security Diagrams Free

- Rack Diagrams Free

- Telecommunication Network Diagrams Free

- Vehicular Networking Free

- Wireless Networks Free

- Comparison Dashboard Free

- Composition Dashboard Free

- Correlation Dashboard Free

- Frequency Distribution Dashboard Free

- Meter Dashboard Free

- Spatial Dashboard Free

- Status Dashboard Free

- Time Series Dashboard Free

- Basic Circle-Spoke Diagrams Free

- Basic Circular Arrows Diagrams Free

- Basic Venn Diagrams Free

- Block Diagrams Free

- Concept Maps Free

- Family Tree Free

- Flowcharts Free

- Basic Area Charts Free

- Basic Bar Graphs Free

- Basic Divided Bar Diagrams Free

- Basic Histograms Free

- Basic Line Graphs Free

- Basic Picture Graphs Free

- Basic Pie Charts Free

- Basic Scatter Diagrams Free

- Aerospace and Transport Free

- Artwork Free

- Audio, Video, Media Free

- Business and Finance Free

- Computers and Communications Free

- Holiday Free

- Manufacturing and Maintenance Free

- Nature Free

- People Free

- Presentation Clipart Free

- Safety and Security Free

- Analog Electronics Free

- Audio and Video Connectors Free

- Basic Circuit Diagrams Free

- Chemical and Process Engineering Free

- Digital Electronics Free

- Electrical Engineering Free

- Electron Tube Circuits Free

- Electronic Block Diagrams Free

- Fault Tree Analysis Diagrams Free

- GHS Hazard Pictograms Free

- Home Automation and Wiring Free

- Mechanical Engineering Free

- One-line Diagrams Free

- Power Сircuits Free

- Specification and Description Language (SDL) Free

- Telecom and AV Circuits Free

- Transport Hazard Pictograms Free

- Data-driven Infographics Free

- Pictorial Infographics Free

- Spatial Infographics Free

- Typography Infographics Free

- Calendars Free

- Decision Making Free

- Enterprise Architecture Diagrams Free

- Fishbone Diagrams Free

- Organizational Charts Free

- Plan-Do-Check-Act (PDCA) Free

- Seven Management and Planning Tools Free

- SWOT and TOWS Matrix Diagrams Free

- Timeline Diagrams Free

- Australia Map Free

- Continent Maps Free

- Directional Maps Free

- Germany Map Free

- Metro Map Free

- UK Map Free

- USA Maps Free

- Customer Journey Mapping Free

- Marketing Diagrams Free

- Matrices Free

- Pyramid Diagrams Free

- Sales Dashboard Free

- Sales Flowcharts Free

- Target and Circular Diagrams Free

- Cash Flow Reports Free

- Current Activities Reports Free

- Custom Excel Report Free

- Knowledge Reports Free

- MINDMAP Reports Free

- Overview Reports Free

- PM Agile Free

- PM Dashboards Free

- PM Docs Free

- PM Easy Free

- PM Meetings Free

- PM Planning Free

- PM Presentations Free

- PM Response Free

- Resource Usage Reports Free

- Visual Reports Free

- House of Quality Free

- Quality Mind Map Free

- Total Quality Management TQM Diagrams Free

- Value Stream Mapping Free

- Astronomy Free

- Biology Free

- Chemistry Free

- Language Learning Free

- Mathematics Free

- Physics Free

- Piano Sheet Music Free

- Android User Interface Free

- Class Hierarchy Tree Free

- Data Flow Diagrams (DFD) Free

- DOM Tree Free

- Entity-Relationship Diagram (ERD) Free

- EXPRESS-G data Modeling Diagram Free

- IDEF0 Diagrams Free

- iPhone User Interface Free

- Jackson Structured Programming (JSP) Diagrams Free

- macOS User Interface Free

- Object-Role Modeling (ORM) Diagrams Free

- Rapid UML Free

- SYSML Free

- Website Wireframe Free

- Windows 10 User Interface Free

Chemical and Process Engineering

Chemical engineering is one of so many different branched of engineering which applies physical sciences (such as chemistry and physics), life sciences (biochemistry and microbiology), economics and applied mathematics to transform, produce, transport and use chemicals, materials, and energy in a proper way.

The process of chemical engineering involves managing different plant conditions and processes to ensure the optimal plant operation. Chemical reaction engineers can construct the needed models to use for the reactor analysis as well as the reactor design by using the available laboratory data and other physical parameters. They solve the chemistry-related problems and they can usually predict any reactor’s performance.

Chemical engineers use their knowledge in both chemistry and engineering for turning the raw materials into some usable products. Any chemical engineer can design some large-scale process, converting raw materials, chemicals, living cells, energy and microorganisms into some useful products and forms, being involved in many aspects of plant operations and design, including safety and hazard assessments, process analysis and design, chemical reaction engineering, control engineering, operating instructions and construction specification.

Being involved in the industry where they are expected to design and perform multiple experiments in order to create better as well as safer methods for pollution control, resource conservation and production, chemical engineers may be involved in constructing and designing plants as if they were project engineers. Thus, serving as project engineers, chemical engineers can use their knowledge while selecting the plant equipment and the most optimal production methods for minimizing costs and maximizing profitability and safety.

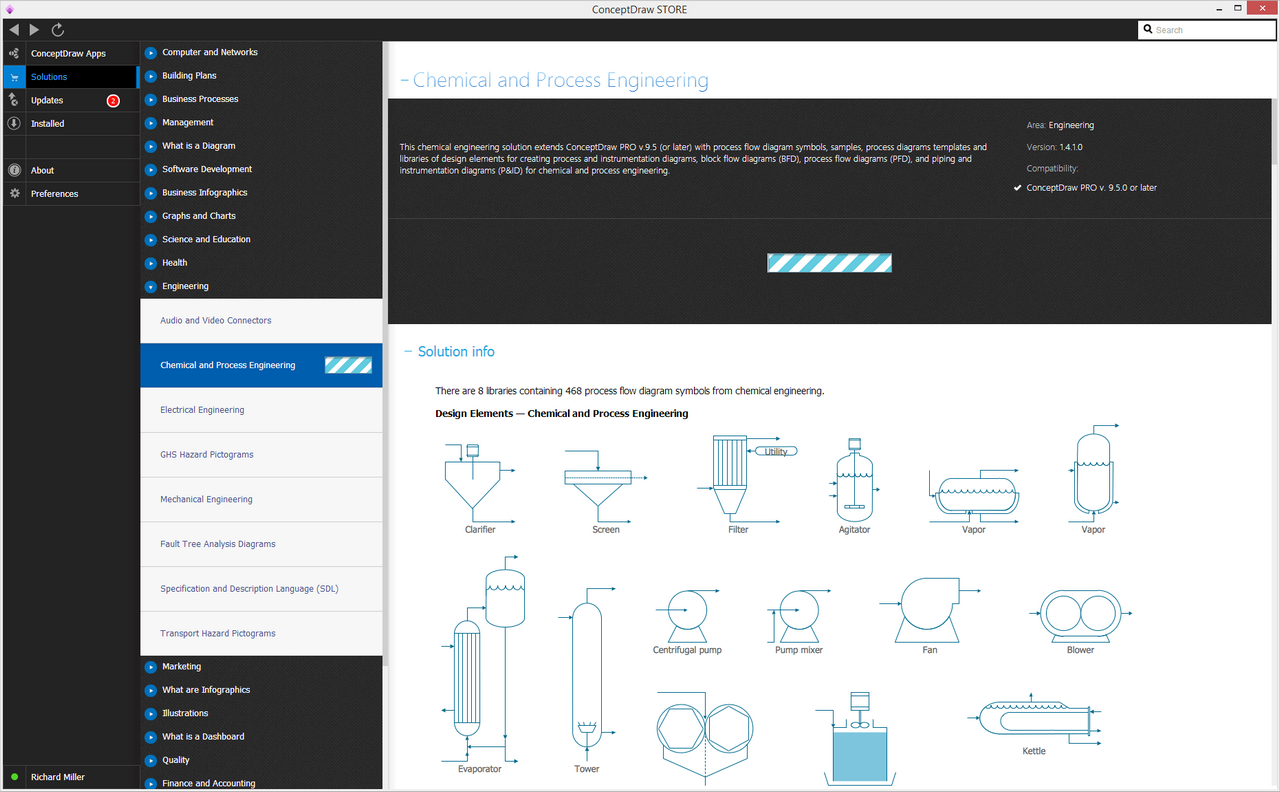

Extending the ConceptDraw DIAGRAM diagramming and drawing software with process flow diagram symbols, samples, process diagrams templates and libraries of design elements for creating process and instrumentation diagrams, block flow diagrams (BFD), process flow diagrams (PFD), and piping and instrumentation diagrams (P&ID) for chemical and process engineering, the Chemical and Process Engineering solution can be used by both chemical and project engineers, as well as the chemists for creating the needed drawings.

-

Install this solution Free -

What I need to get started -

Solution Requirements - This solution requires the following products to be installed:

ConceptDraw DIAGRAM v18 - This solution requires the following products to be installed:

-

Compatibility - Sonoma (14), Sonoma (15)

MS Windows 10, 11 - Sonoma (14), Sonoma (15)

-

Support for this Solution -

Helpdesk

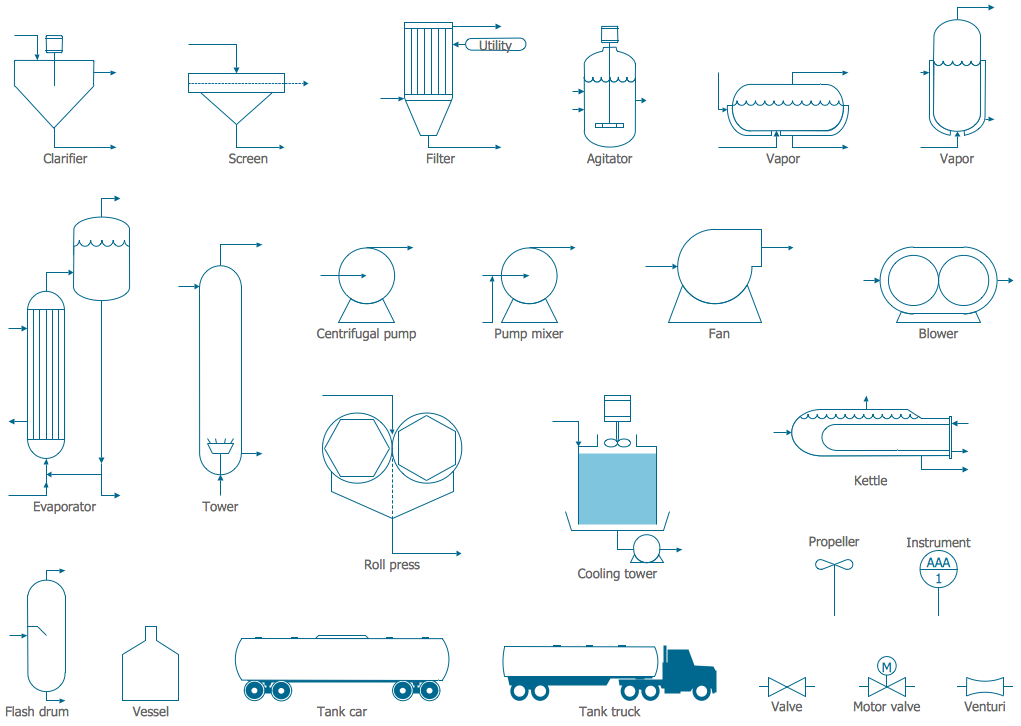

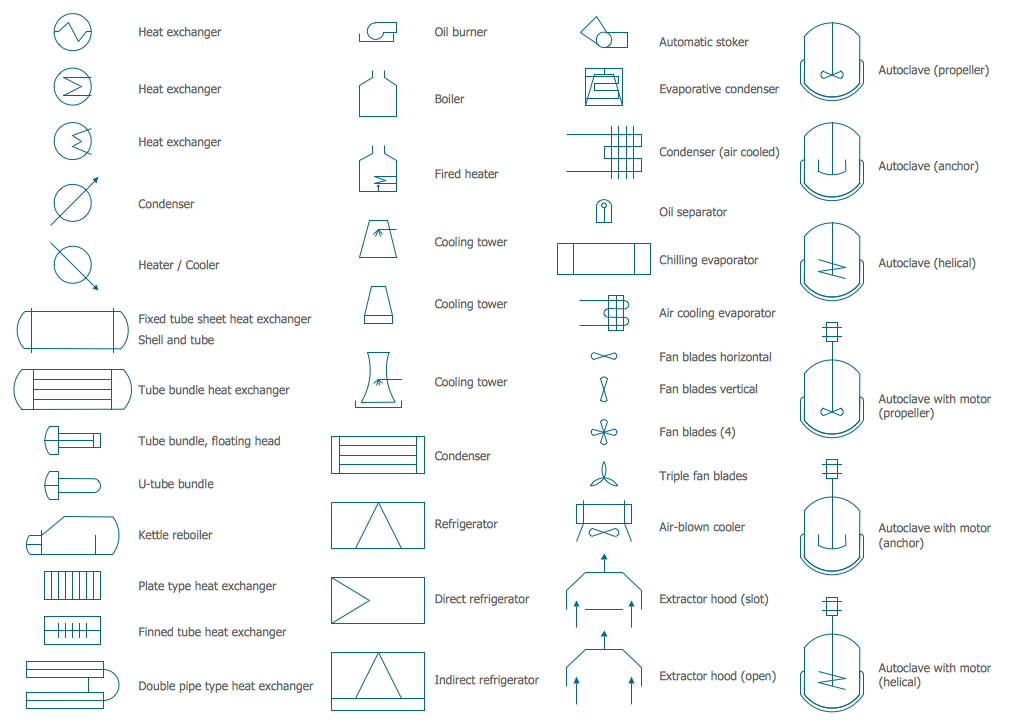

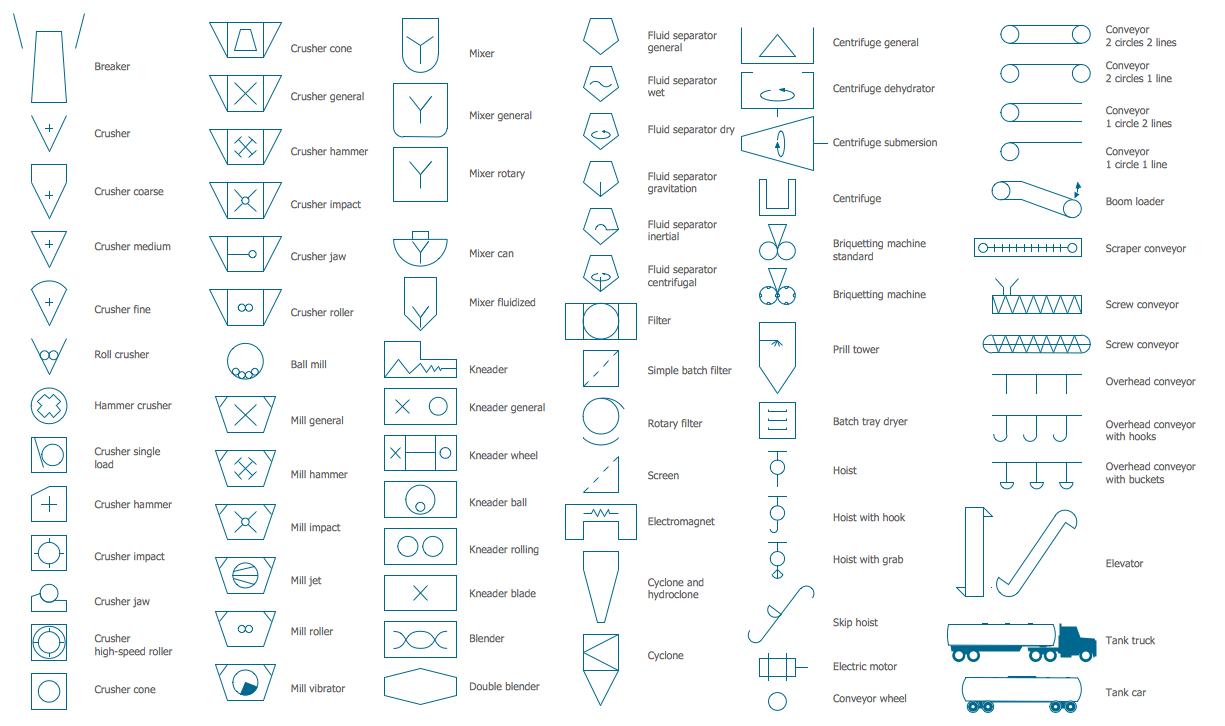

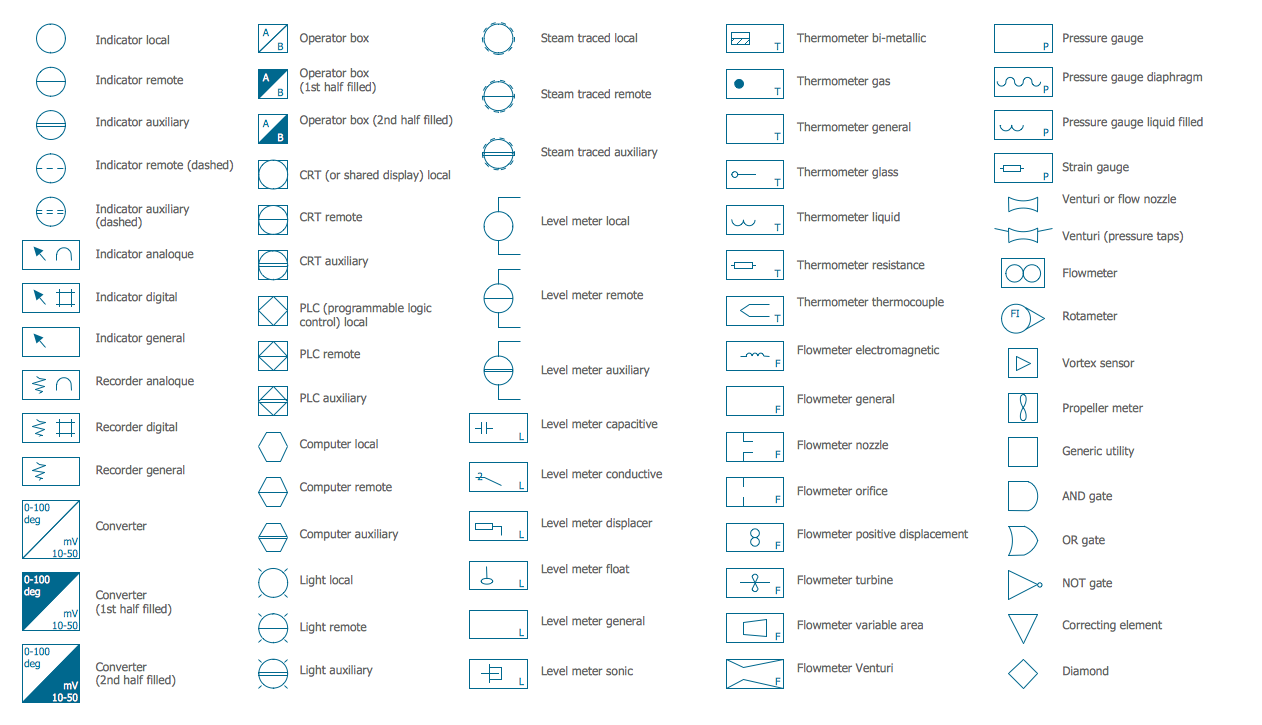

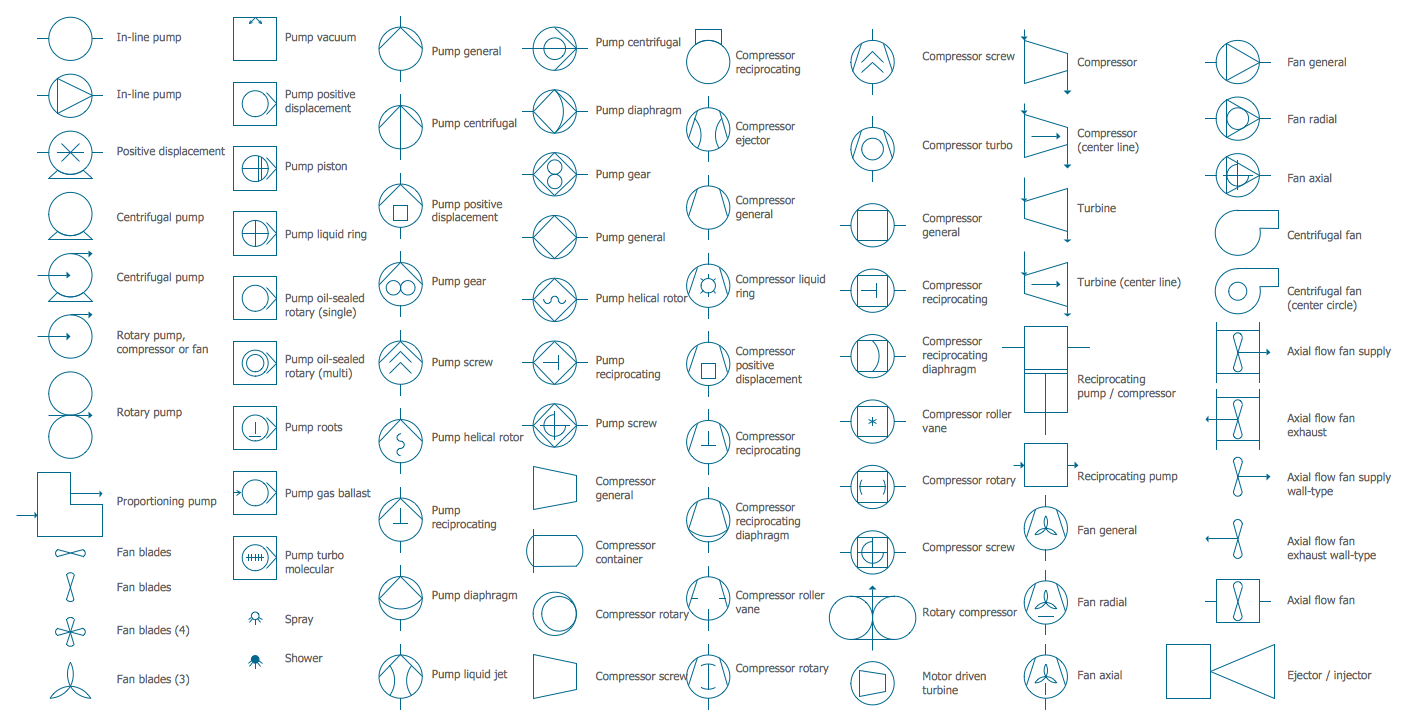

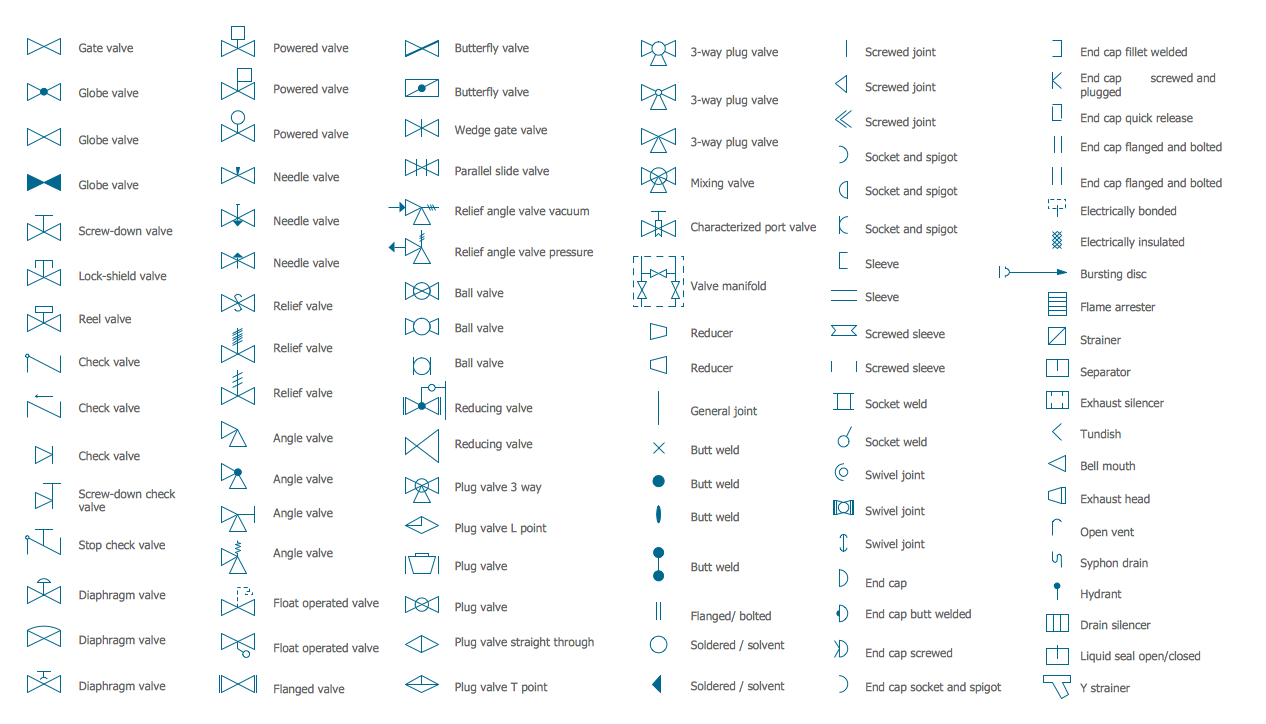

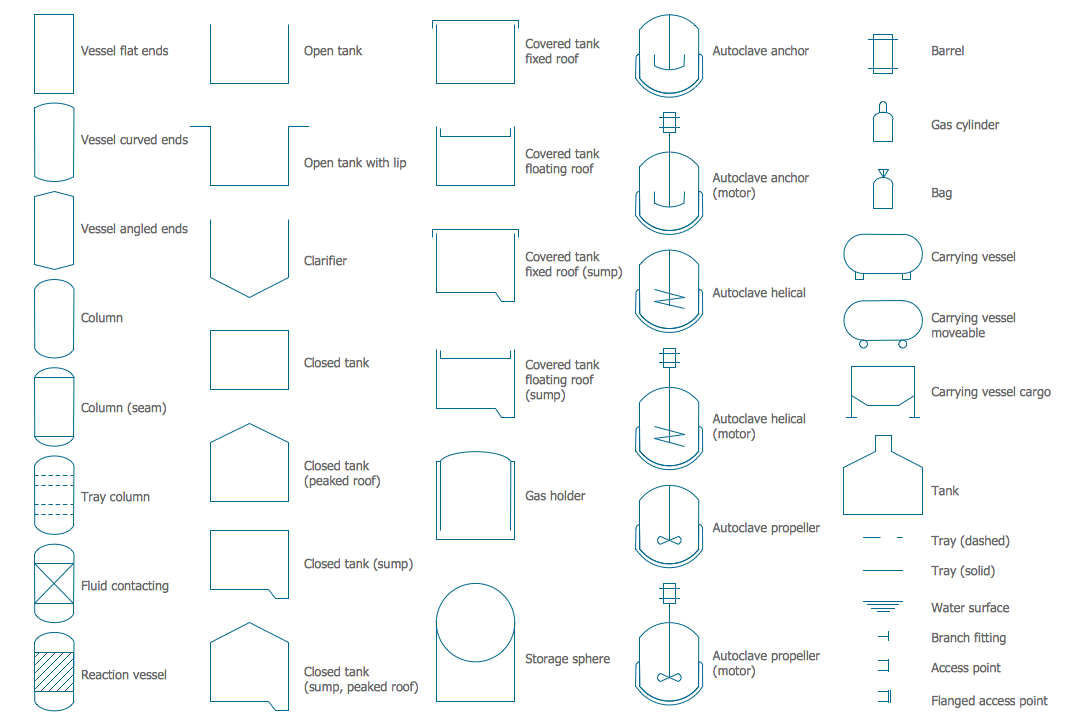

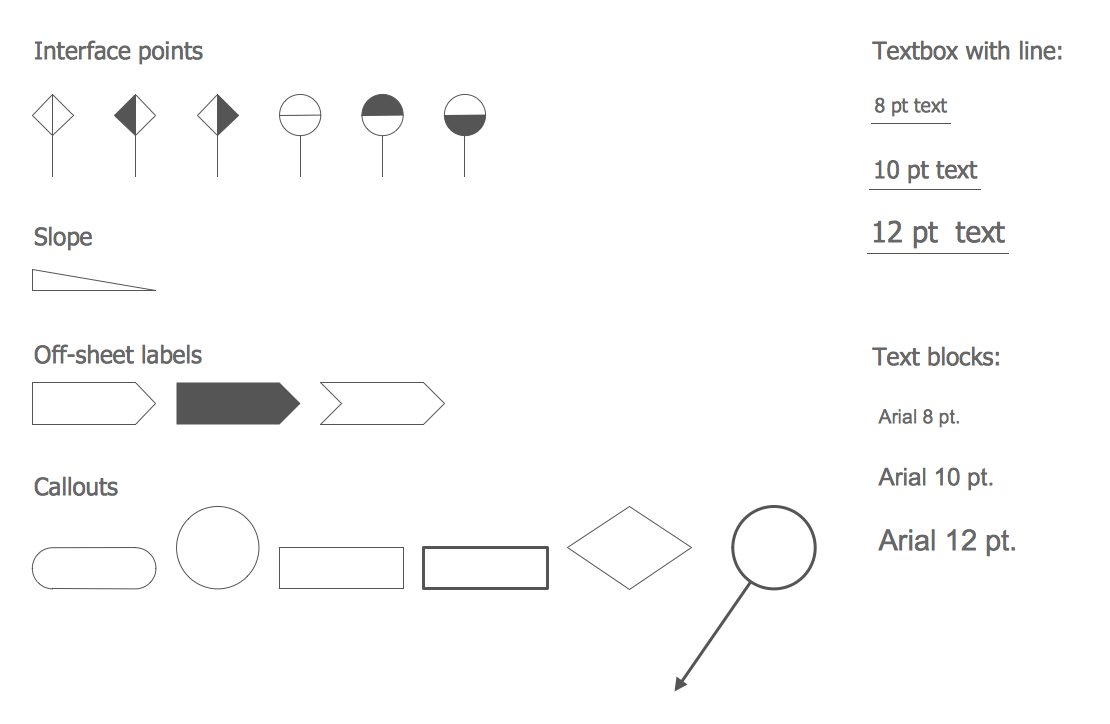

There are 8 libraries containing 468 process flow diagram symbols from chemical engineering.

Design Elements — Chemical and Process Engineering

Design Elements — Heating Equipment

Design Elements — Industrial Equipment

Design Elements — Instruments

Design Elements — Pumps

Design Elements — Valves and Fittings

Design Elements — Vessels

Design Elements — Process Annotation

Examples

There are a few samples that you see on this page which were created in the ConceptDraw DIAGRAM application by using the Chemical and Process Engineering solution. Some of the solution's capabilities as well as the professional results which you can achieve are all demonstrated here on this page.

All source documents are vector graphic documents which are always available for modifying, reviewing and/or converting to many different formats, such as MS PowerPoint, PDF file, MS Visio, and many other graphic ones from the ConceptDraw Solution Park or ConceptDraw STORE. The Chemical and Process Engineering solution is available to all ConceptDraw DIAGRAM users to get installed and used while working in the ConceptDraw DIAGRAM diagramming and drawing software.

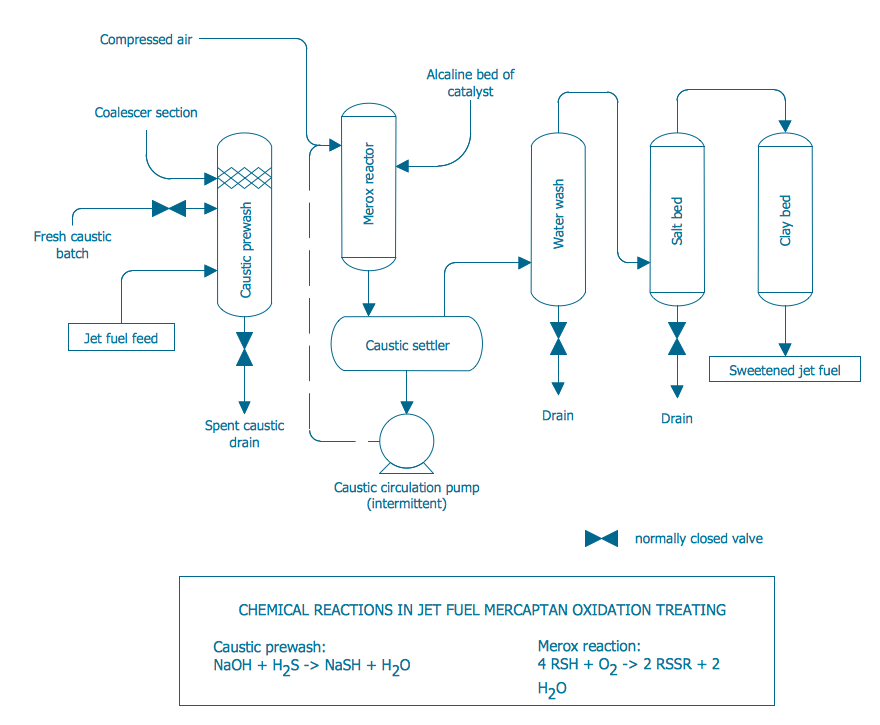

Example 1: Process Diagram — Conventional Merox Process Unit for Sweetening Jet Fuel or Kerosene

This diagram was created in ConceptDraw DIAGRAM using the Vessels, Valves and Fittings, and Pumps Libraries from the "Chemical and Process Engineering" Solution. An experienced user spent 10 minutes creating this sample.

This sample shows a flow diagram describing the process of mercaptan extraction using a conventional mercaptan oxidation treating unit. Use the "Chemical and Process Engineering" Solution for ConceptDraw DIAGRAM to design any process and instrumentation diagram, or process diagrams quickly and easily.

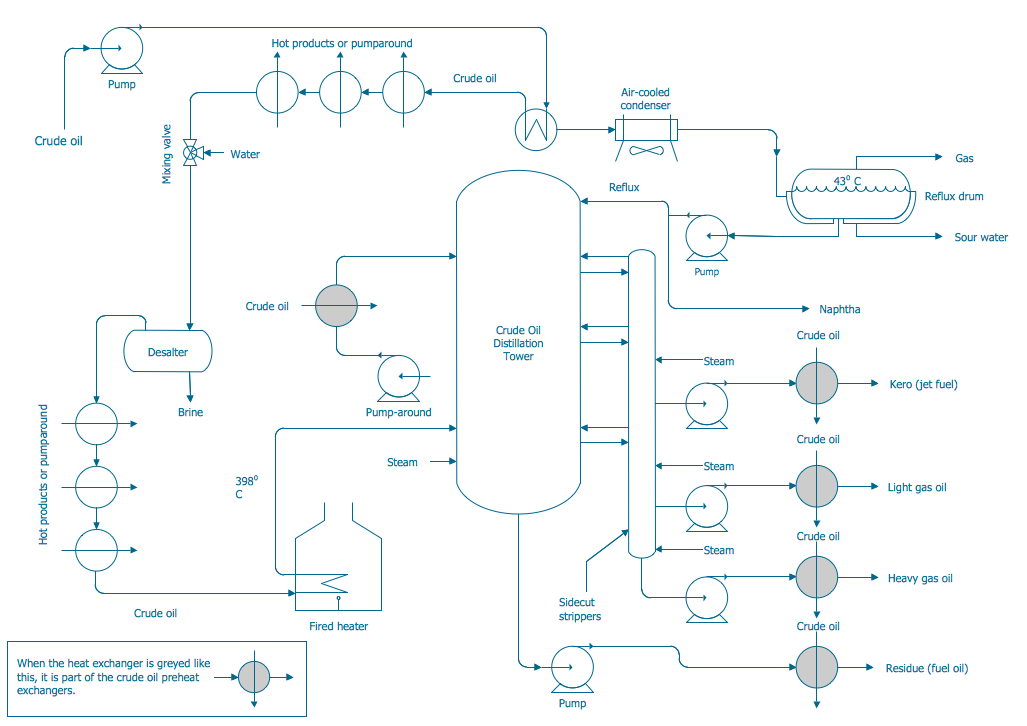

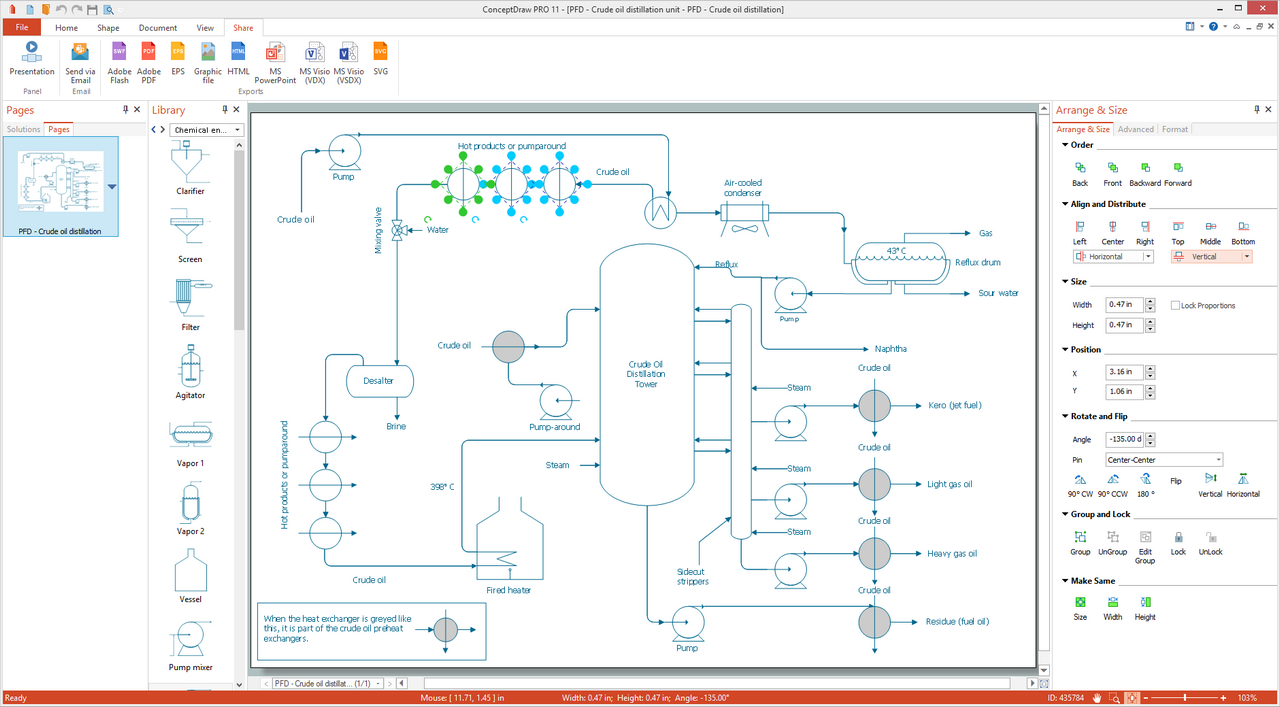

Example 2: PFD — Crude Oil Distillation

This diagram was created in ConceptDraw DIAGRAM using the Chemical Engineering and Pumps Libraries from the "Chemical and Process Engineering" Solution. An experienced user spent 20 minutes creating this sample.

This sample demonstrates a schematic flow diagram of a typical crude oil distillation unit that is used in petroleum crude oil refineries. It is a detailed process engineering diagram designed with the help of process flow diagram symbols from the libraries of the "Chemical and Process Engineering" Solution.

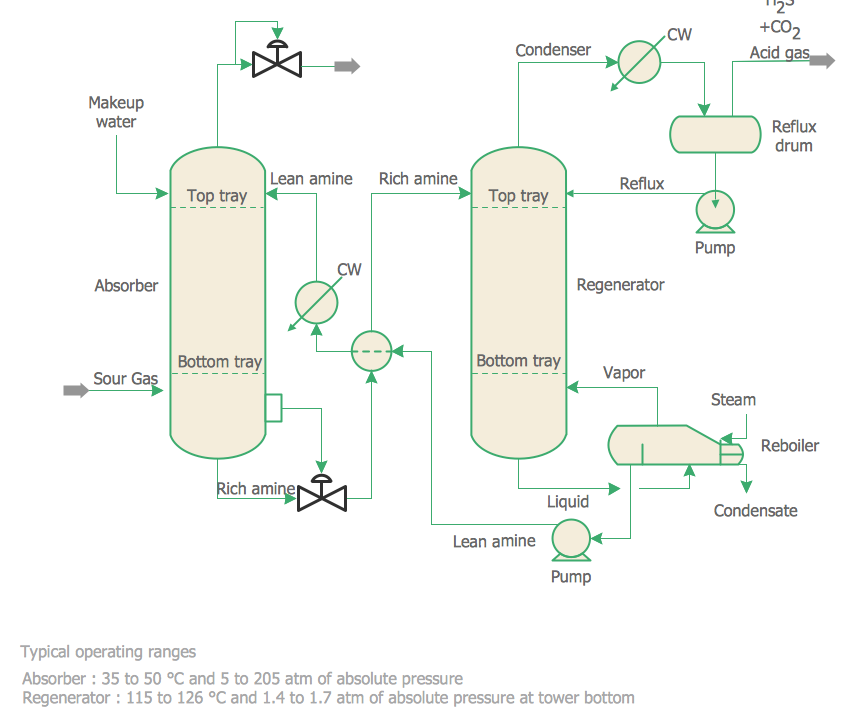

Example 3: Chemical Engineering — Amine Treating Unit Schematic Diagram

This diagram was created in ConceptDraw DIAGRAM using the Vessels, Pumps and Heating Equipment Libraries from the "Chemical and Process Engineering" Solution. An experienced user spent 15 minutes creating this sample.

This sample diagram visualizes Amine Treating. Chemical engineering is an industry which perpetually calls for a large quantity of diagrams and schemes of different complexity. Using ConceptDraw DIAGRAM will help you cope with this task in the most effective manner.

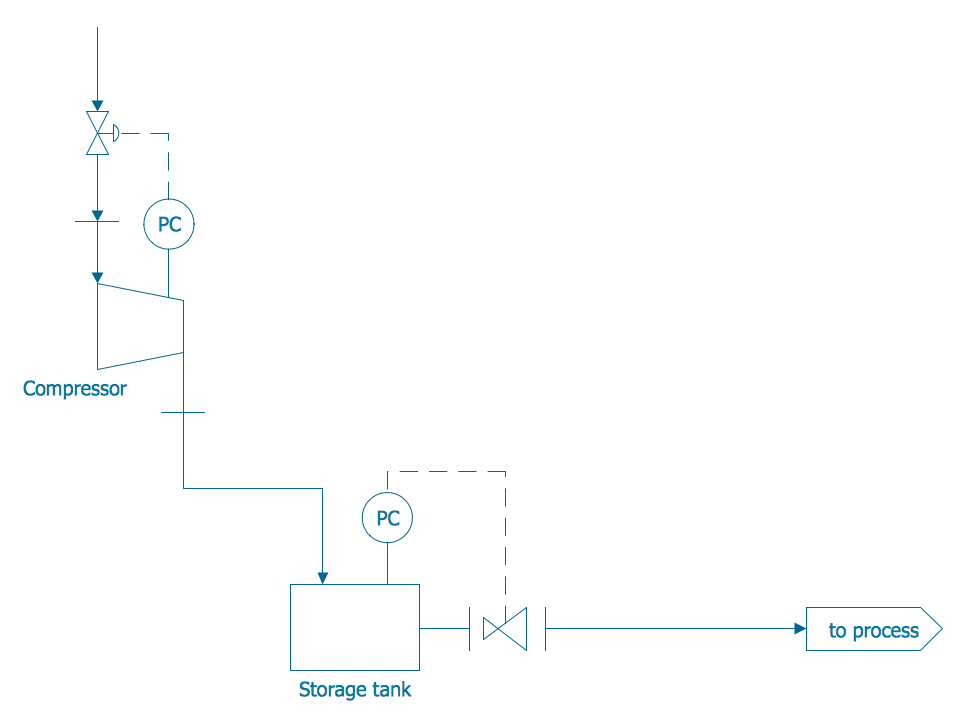

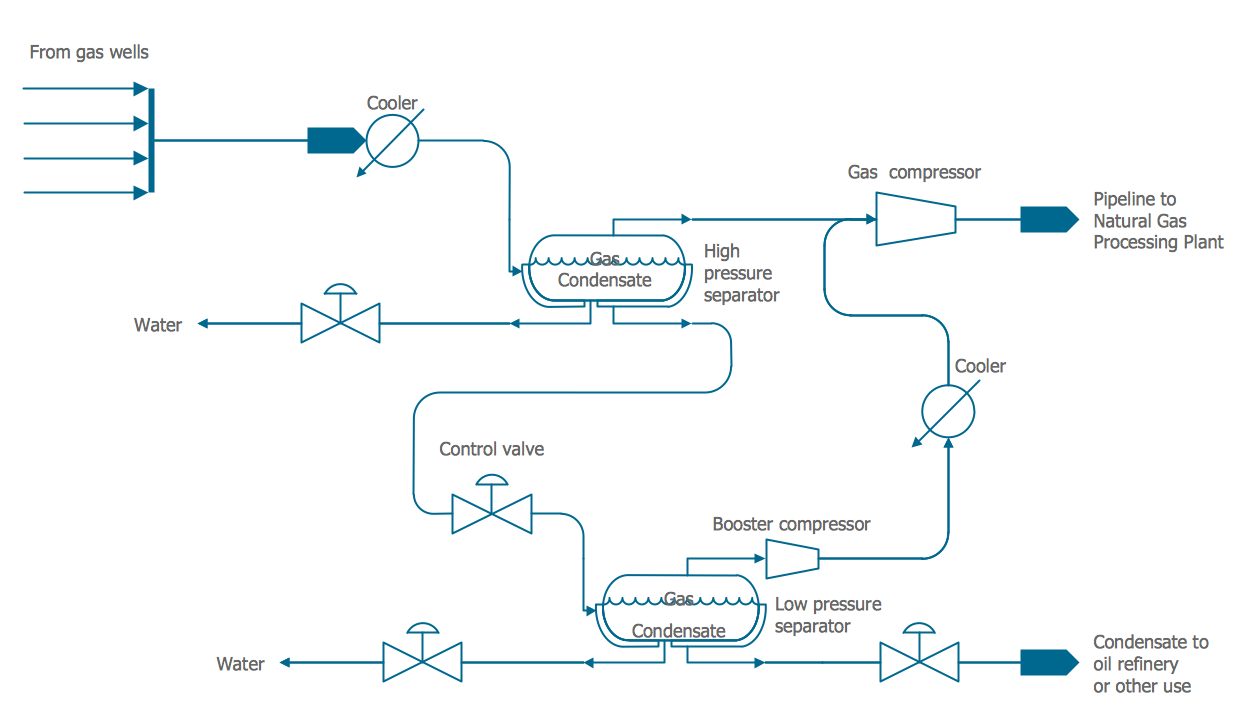

Example 4: Flow Diagram — Natural Gas Condensate

This diagram was created in ConceptDraw DIAGRAM using the Heating Equipment, Chemical Engineering, Valves and Fittings, and Process Annotations Libraries from the "Chemical and Process Engineering" Solution. An experienced user spent 10 minutes creating this sample.

There are many different equipment configurations utilized for the process of separating condensate from raw natural gas. This sample illustrates the flow diagram of one such system.

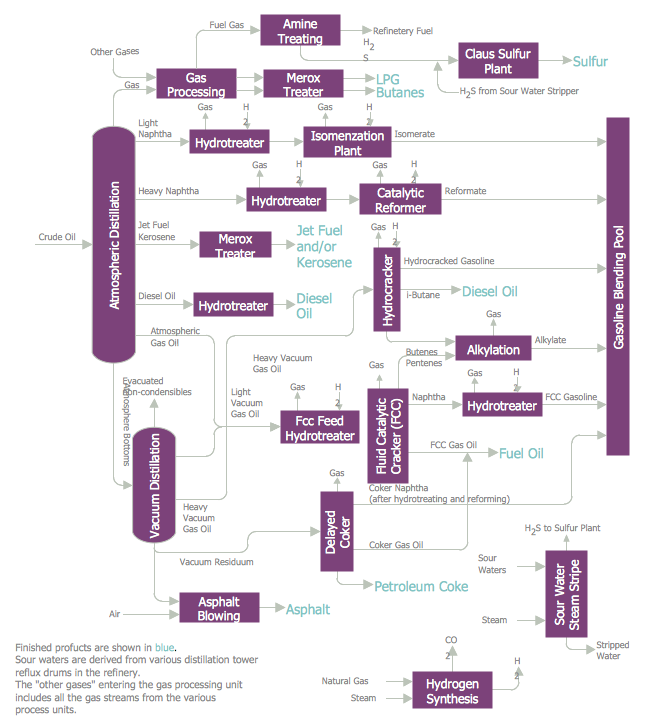

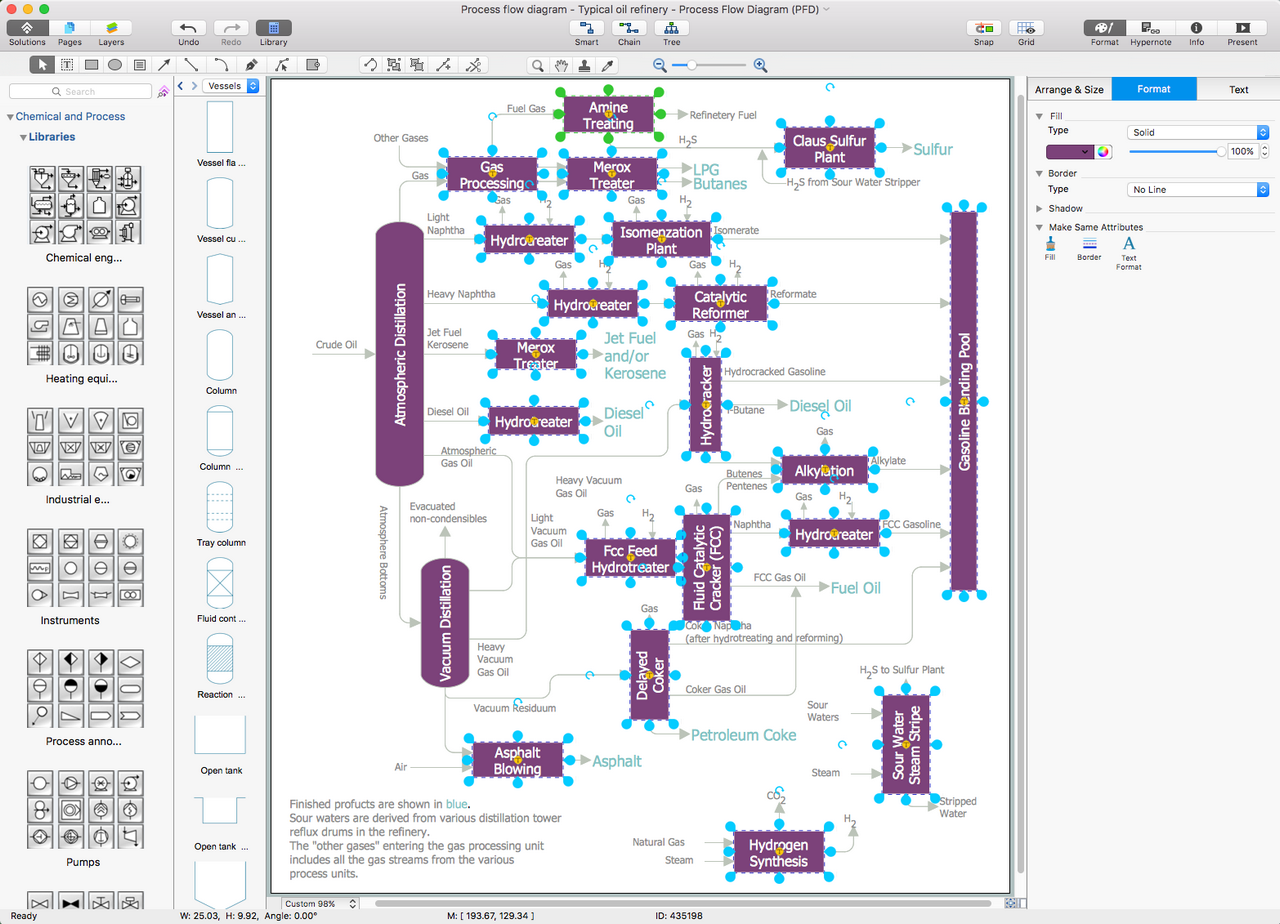

Example 5: Flow Diagram — Typical Oil Refinery

This diagram was created in ConceptDraw DIAGRAM using the Vessels Library from the "Chemical and Process Engineering" Solution. An experienced user spent 20 minutes creating this sample.

This sample shows the complex flow diagram of a typical oil refinery. You can see all processes and the flow of intermediate product streams that take place between the inlet crude oil feedstock and the final end products.

More Examples and Templates

Inside

What I Need to Get Started

Both ConceptDraw DIAGRAM diagramming and drawing software and the Chemical and Process Engineering solution can help creating the illustrations the technical documentation of an engineering projects you need. The Chemical and Process Engineering solution can be found in the Industrial Engineering area of ConceptDraw STORE application that can be downloaded from this site. Make sure that both ConceptDraw DIAGRAM and ConceptDraw STORE applications are installed on your computer before you get started.

How to install

After ConceptDraw STORE and ConceptDraw DIAGRAM are downloaded and installed, you can install the Chemical and Process Engineering solution from the ConceptDraw STORE.

Start Using

To make sure that you are doing it all right, use the pre-designed symbols from the stencil libraries from the solution to make your drawings look smart and professional. Also, the pre-made examples from this solution can be used as drafts so your own drawings can be based on them. Using the samples, you can always change their structures, colors and data.