Value Stream Mapping

Value Stream Mapping

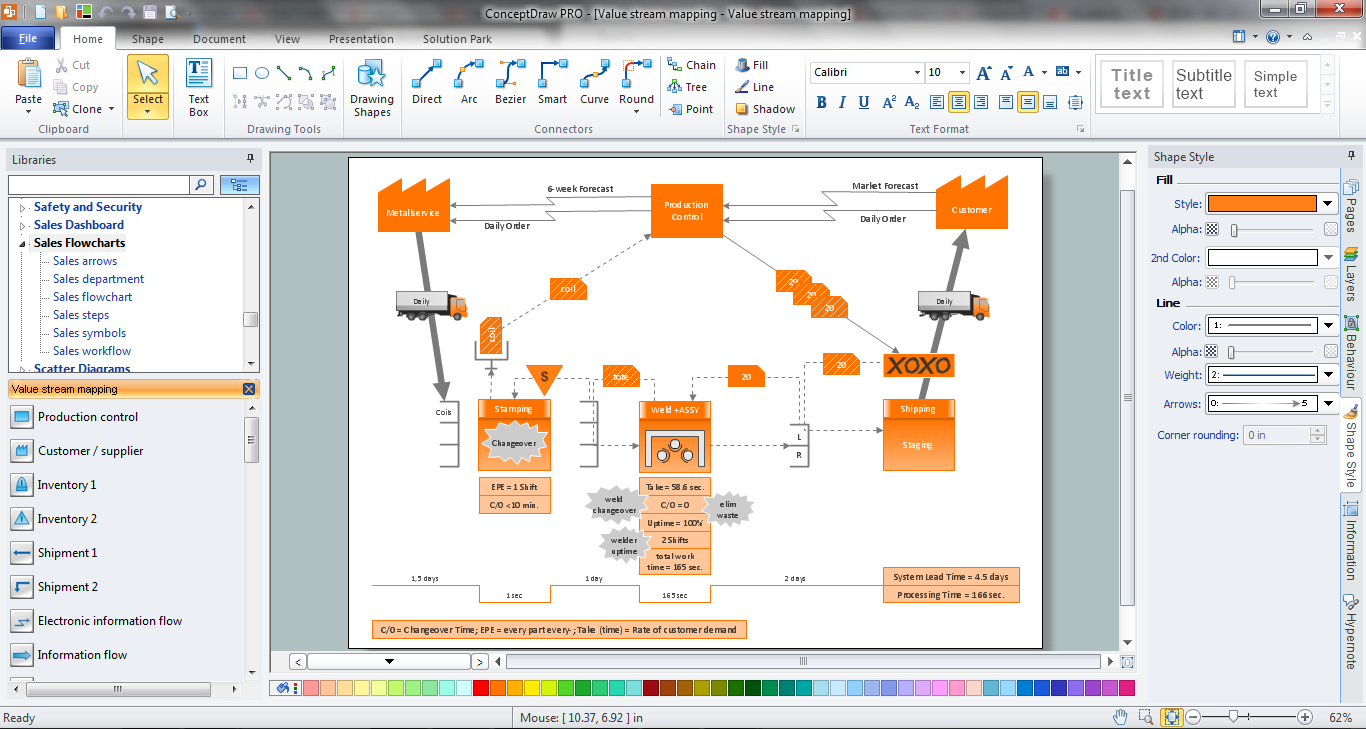

Value stream mapping solution extends ConceptDraw PRO software with templates, samples and vector stencils for drawing the Value Stream Maps (VSM) in lean manufacturing practice.

"Value Stream Mapping (VSM):

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

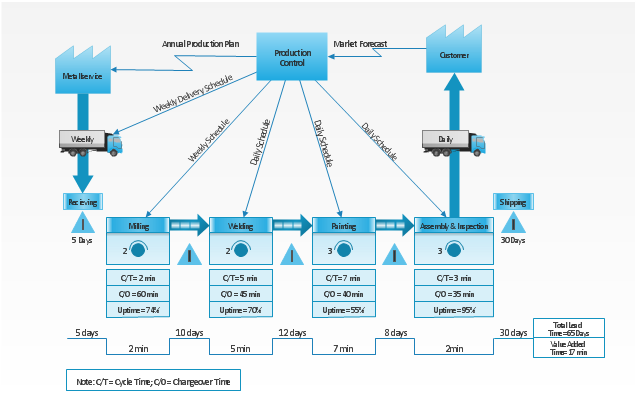

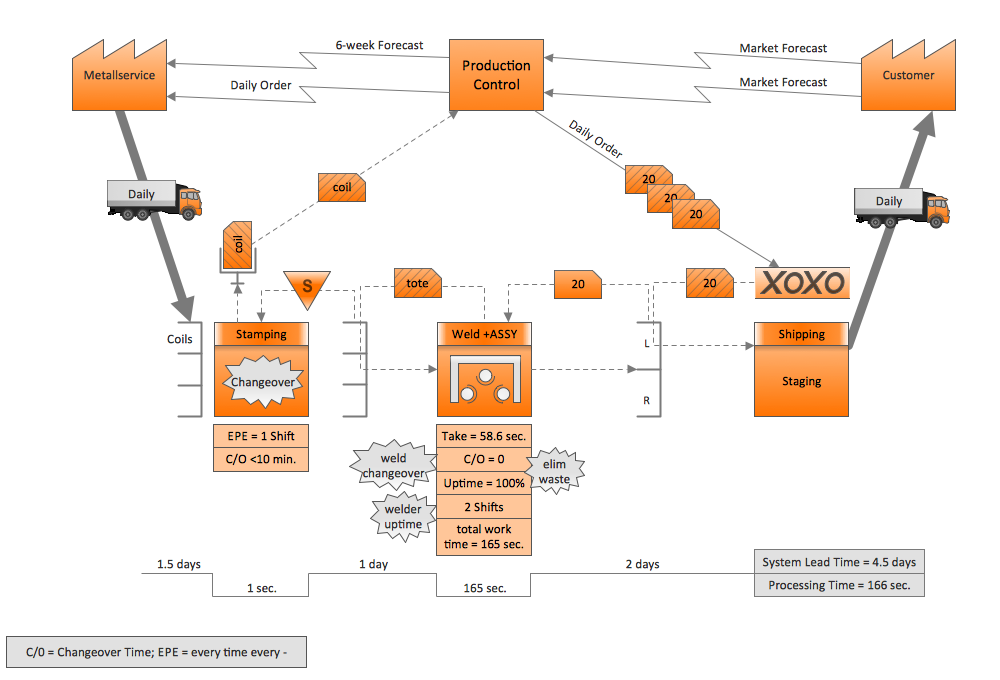

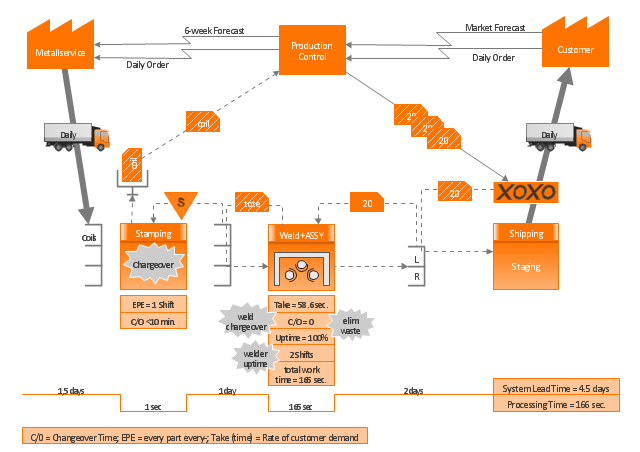

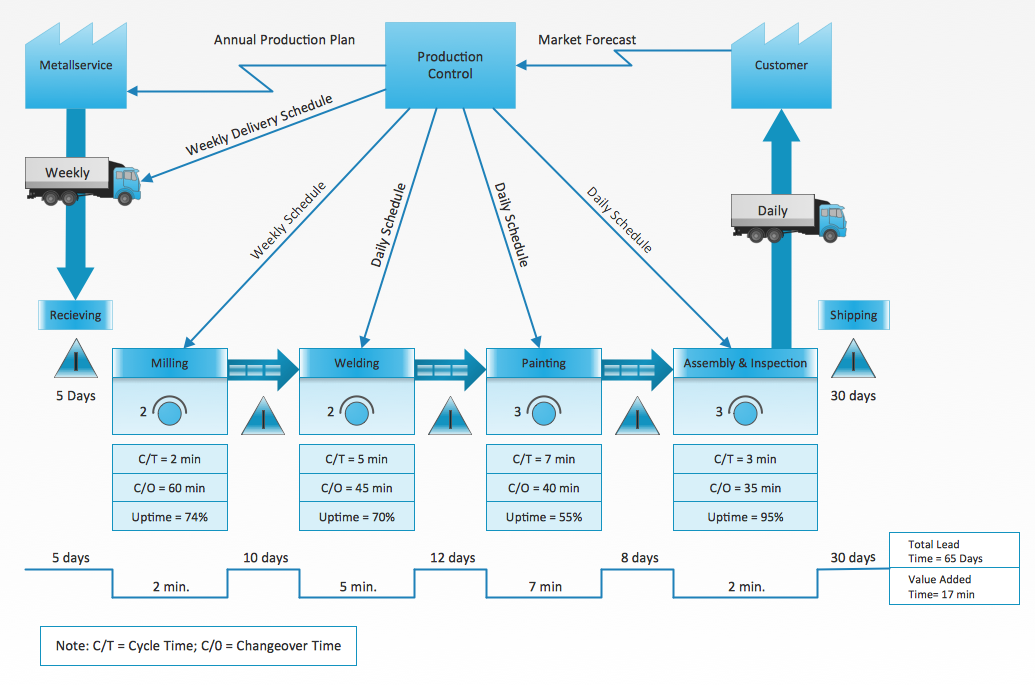

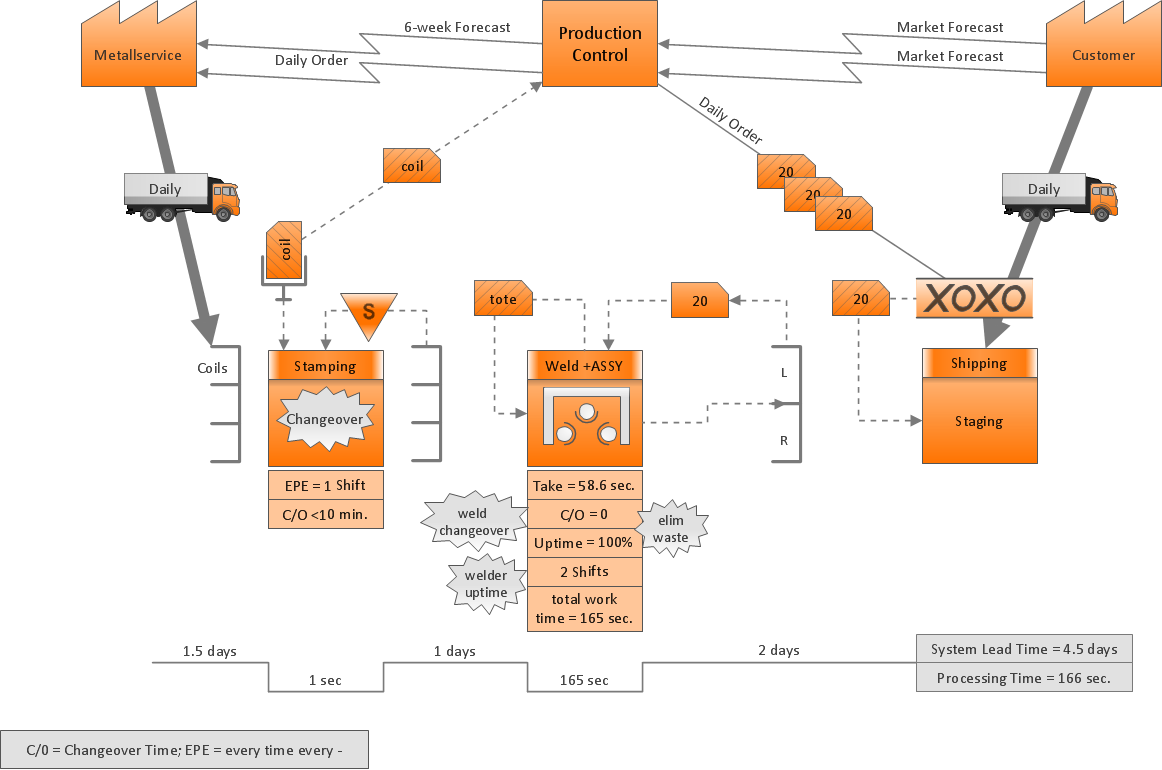

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

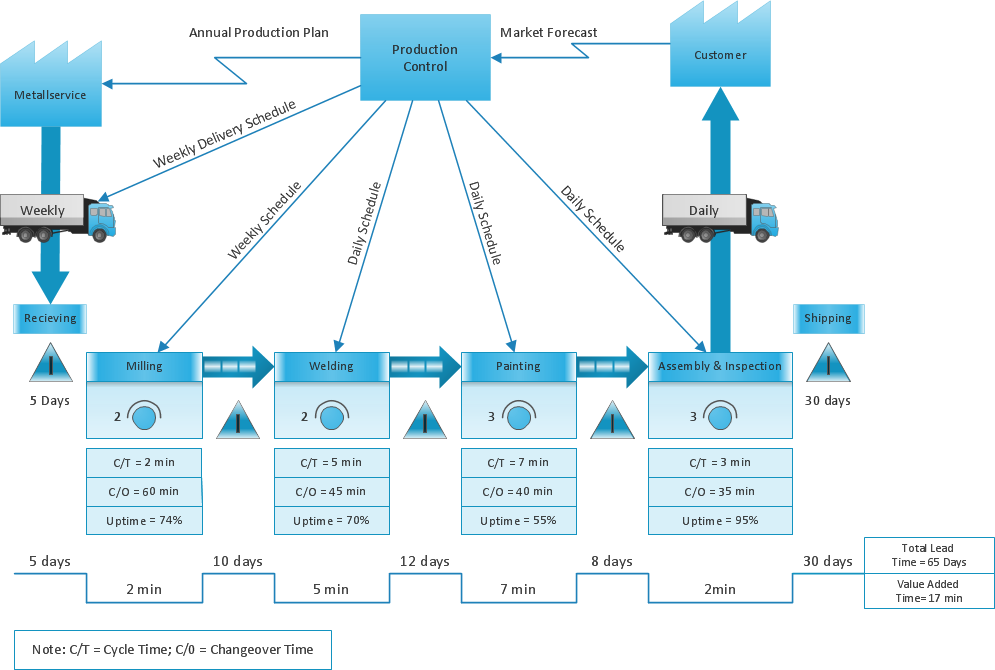

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

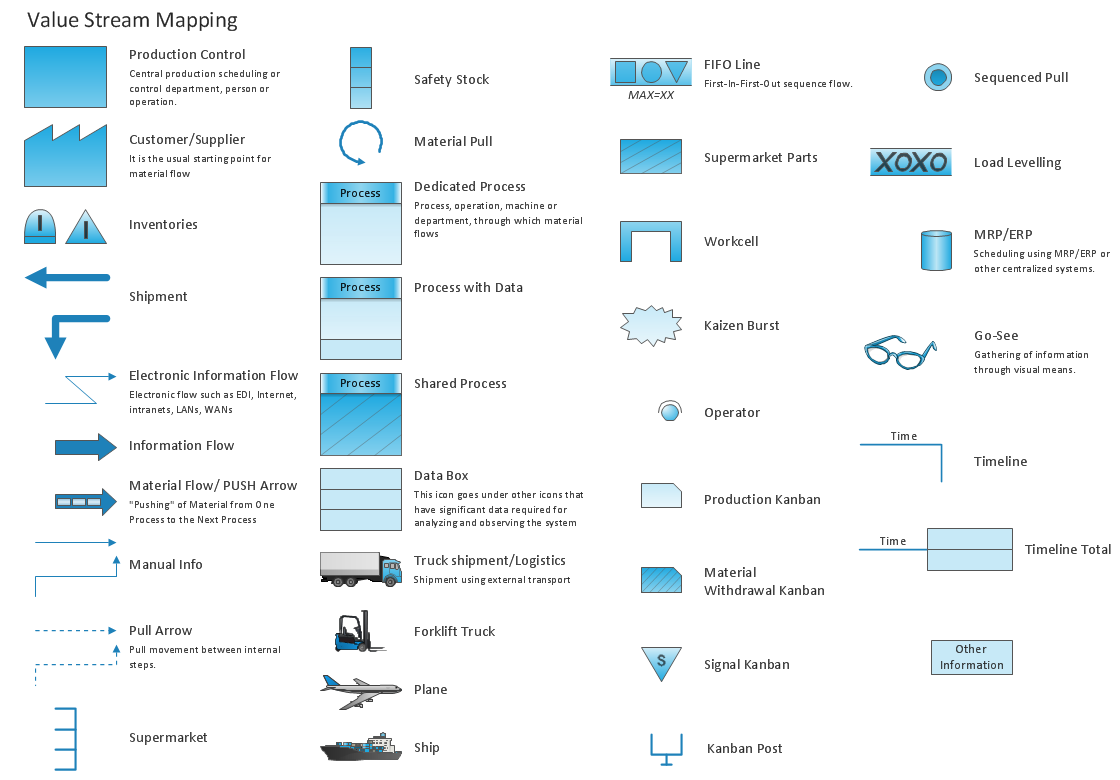

Value Stream Mapping Symbols

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.Value stream with ConceptDraw PRO

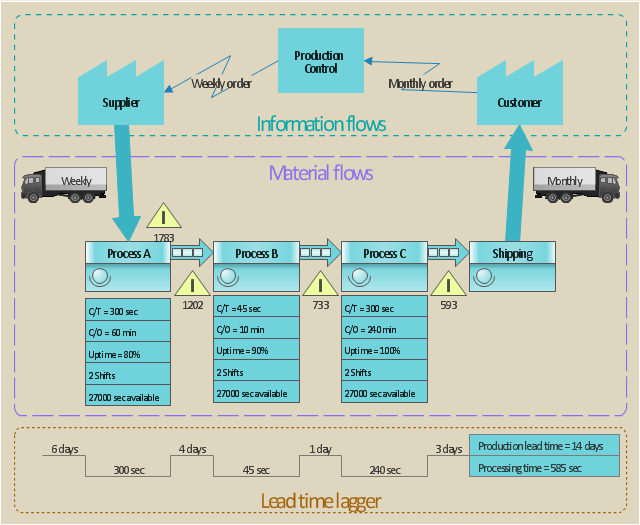

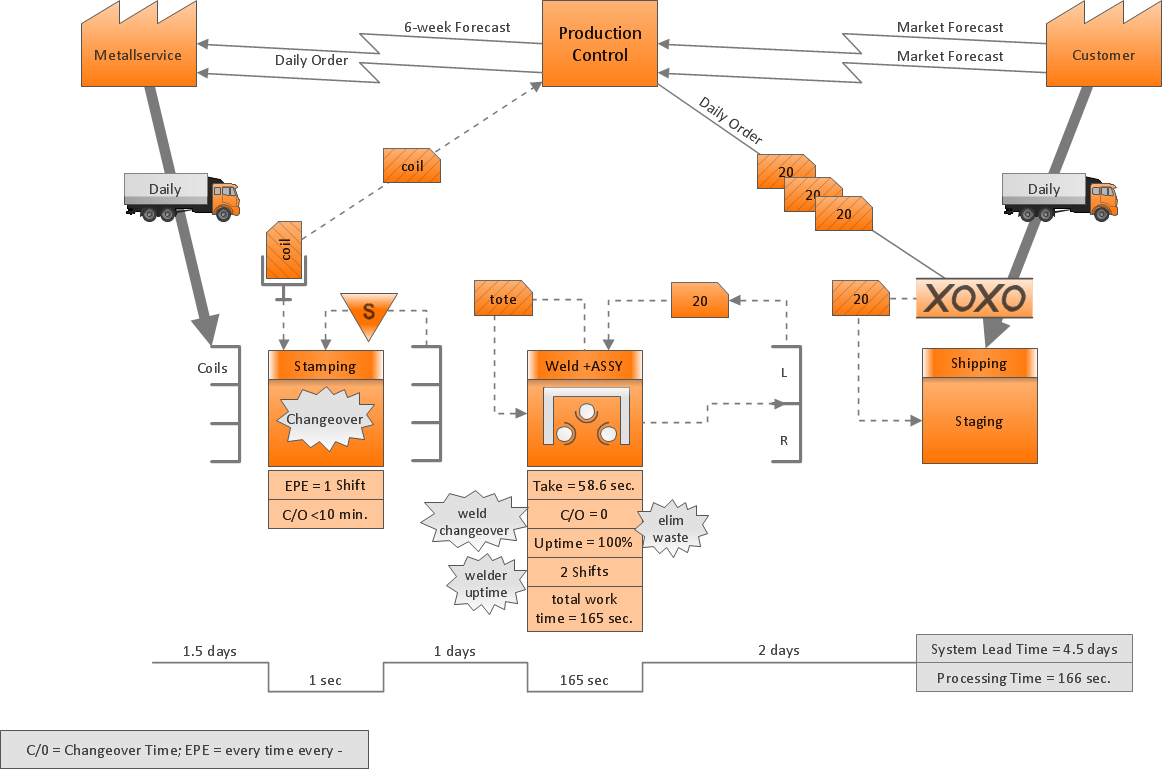

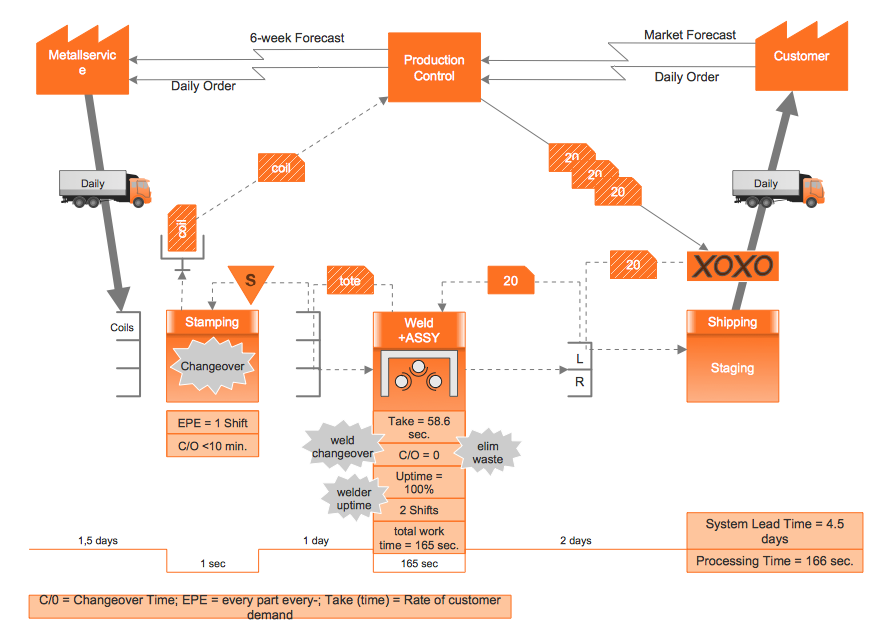

The Value stream is a totality of all actions on the projection, order composition and production: starting from creation a product project to launching this product, from order to delivery, from extraction of raw materials to ready product manufacturing. Value stream mapping is a process of visualization of these actions and creation of a detailed and graphical map.This value stream map example was redesigned from the Wikipedia file: ValueStreamMapParts.png.

[en.wikipedia.org/ wiki/ File:ValueStreamMapParts.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Value stream mapping (VSM) refers to the activity of developing a visual representation of the flow of processes, from start to finish, involved in delivering a desired outcome, service, or product (a “value stream”) that is valued by customers. In the context of government, a value stream could be the process of conducting an audit, completing a procurement, or hiring new agency staff. VSM can increase understanding of actual decision-making processes and identify sources of non-value-added time (e.g., documents waiting to be reviewed). The typical products of a 2-5 day VSM workshop are a map of the “current state” of targeted processes and a “future state” map of the desired process flow and an associated implementation plan for future process improvement activities." [en.wikibooks.org/ wiki/ Business_ Analysis_ Guidebook/ LEAN]

The VSM diagram example "Value stream map parts" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

[en.wikipedia.org/ wiki/ File:ValueStreamMapParts.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Value stream mapping (VSM) refers to the activity of developing a visual representation of the flow of processes, from start to finish, involved in delivering a desired outcome, service, or product (a “value stream”) that is valued by customers. In the context of government, a value stream could be the process of conducting an audit, completing a procurement, or hiring new agency staff. VSM can increase understanding of actual decision-making processes and identify sources of non-value-added time (e.g., documents waiting to be reviewed). The typical products of a 2-5 day VSM workshop are a map of the “current state” of targeted processes and a “future state” map of the desired process flow and an associated implementation plan for future process improvement activities." [en.wikibooks.org/ wiki/ Business_ Analysis_ Guidebook/ LEAN]

The VSM diagram example "Value stream map parts" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

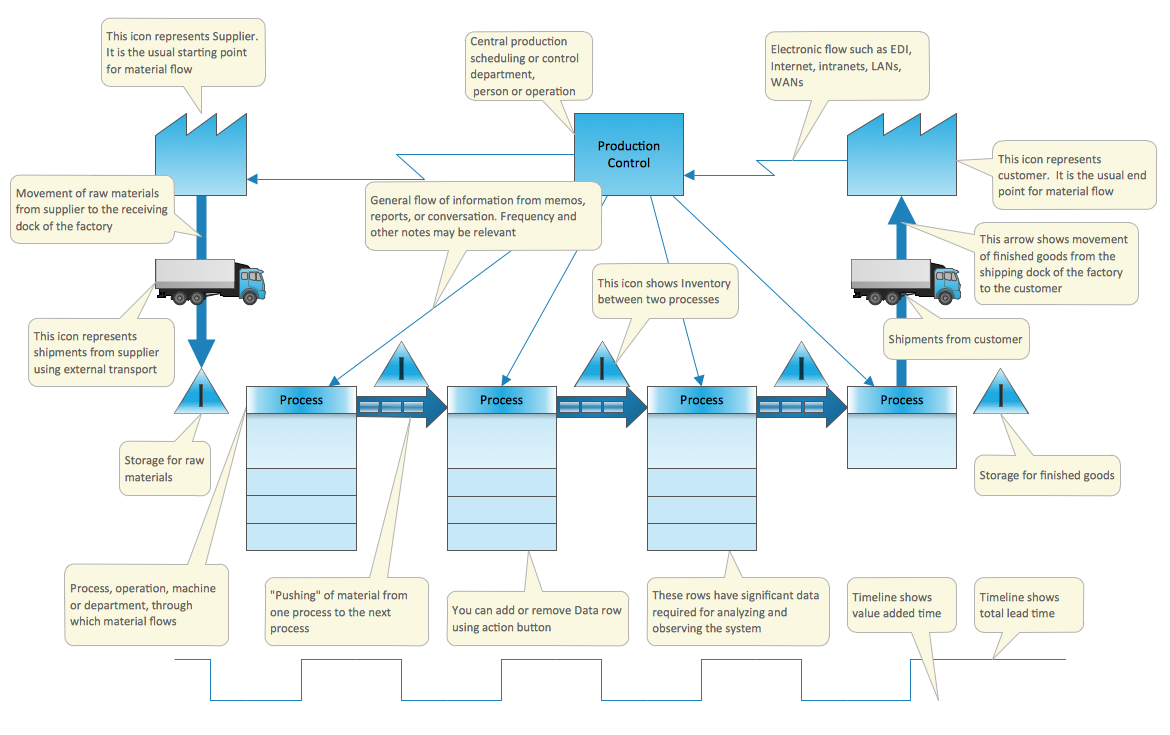

Value Stream Mapping Template

Use ConceptDraw PRO extended with Value Stream Mapping solution for document processes with professional designed Value Stream Mapping template.Quality Engineering Diagrams

Create Quality Engineering Diagrams (value stream maps) - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw."Value Stream Map (VSM)

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

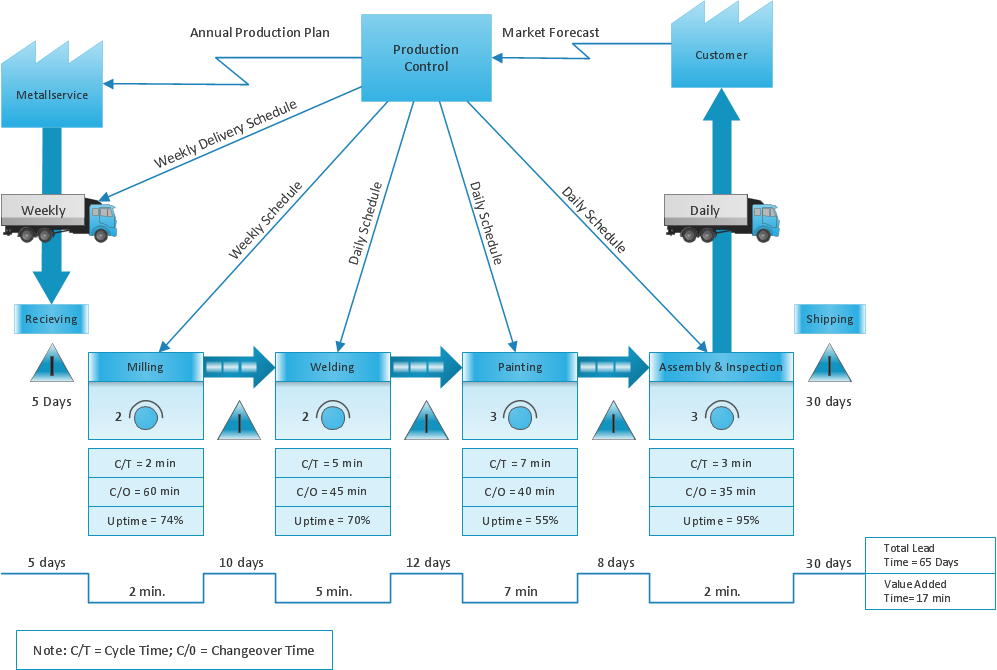

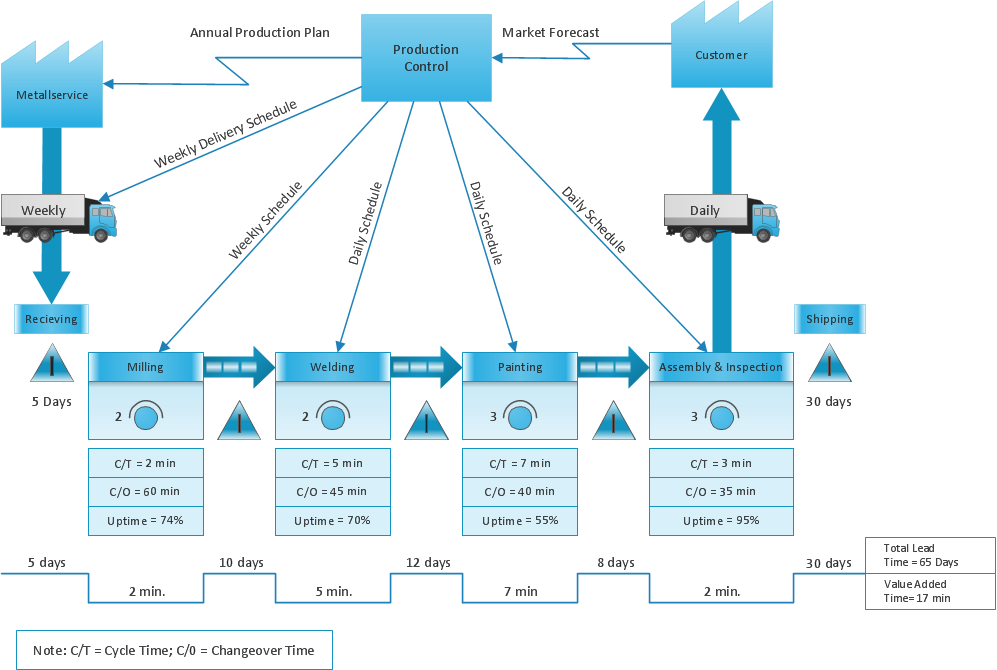

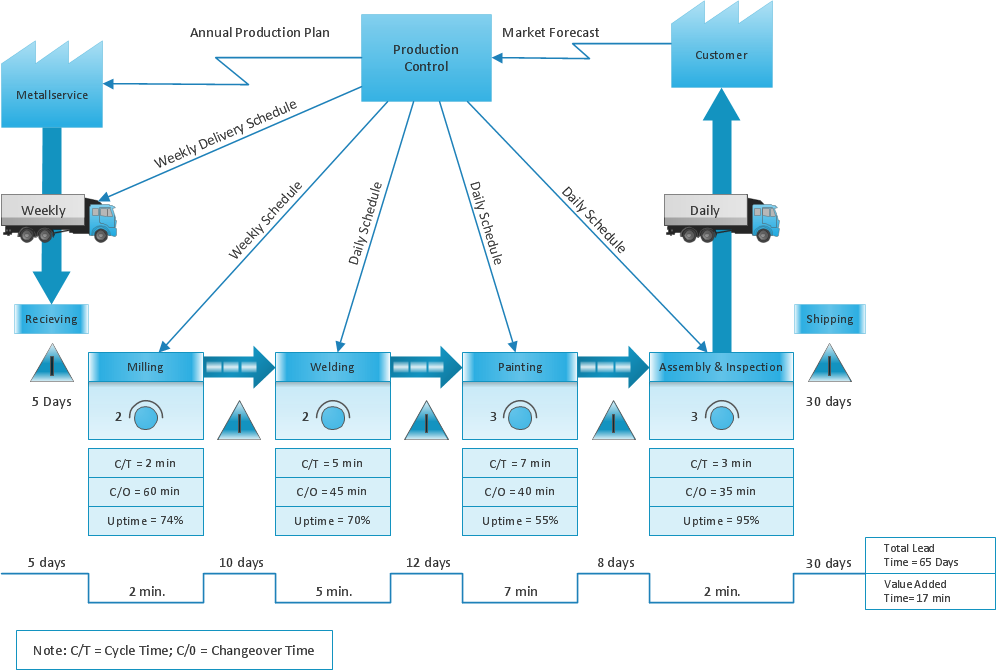

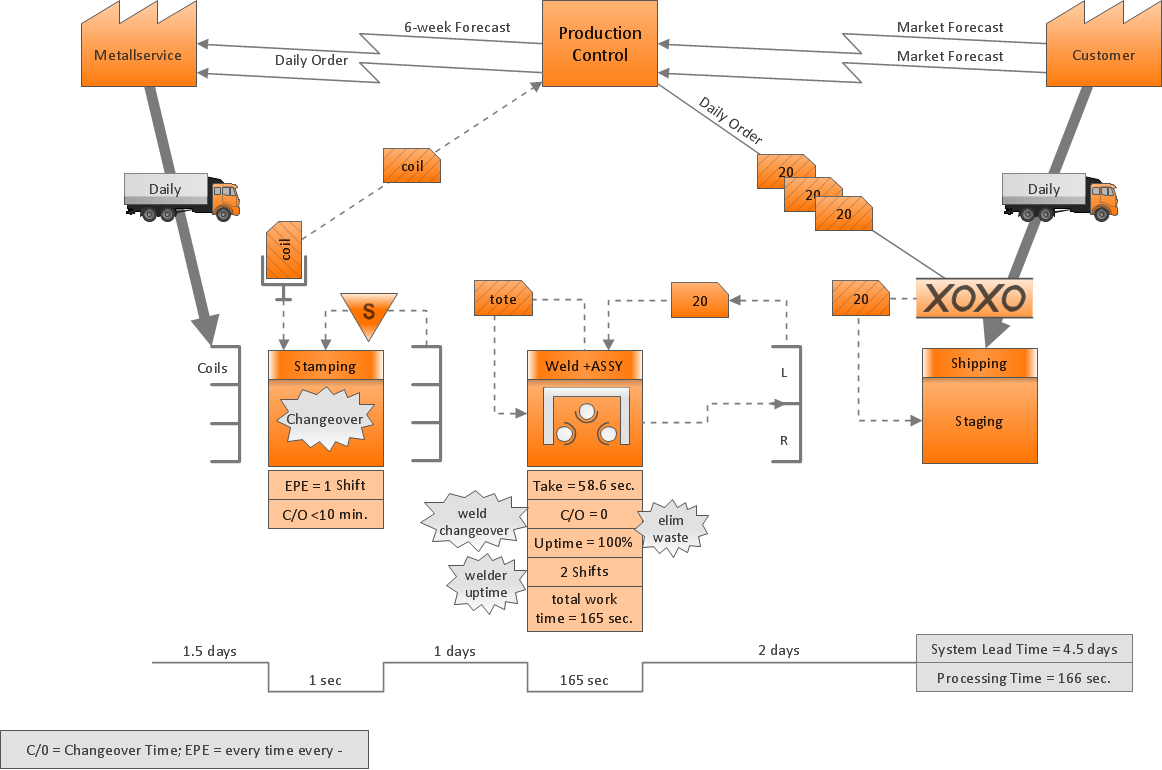

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

Create a Value Stream Map

Use ConceptDraw PRO software extended with Value Stream Mapping solution to create your own VSM diagrams.Lean Value Stream Map

Lean Manufacturing tool is a new Value Stream Mapping solution found in the ConceptDraw Solution Park.Value Stream Diagram

The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool.What is Value Stream Mapping?

Value stream maps (VSM) are an essential tool for organizations applying Lean methods.Sections of the Value Stream Map

The Value Stream Mapping solution extends ConceptDraw PRO software with a new library that contain vector objects, samples and templates.Value Stream Mapping for the Lean Office

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process.Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.HelpDesk

How to Create a VSM Diagram Using ConceptDraw Value Stream Mapping Solution

Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value Stream Mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Many organizations use value stream mapping as a key portion of their lean efforts. Value Stream Maps are used to analyze and design the flow of materials and information required to bring a product or service to a consumer. You can create a Value Stream Mapping flowchart using ConceptDraw PRO tools.Value Stream Mapping

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product/service to customers. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes in any organization.Best Value Stream Mapping mac Software

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Value Stream Analysis

ConceptDraw Value Stream Maps are used in lean practice for analysis of manufacturing processes to identify the improvement opportunities.- What is Value Stream Mapping ? | Value stream map example ...

- What is Value Stream Mapping ? | Value Stream Analysis | Value ...

- Value stream map example

- Value Stream Mapping Symbols | Design elements - Value stream ...

- Value stream map example | Marketing | Management | Timeline ...

- Vsm Sample

- Value stream map example

- Value Stream Mapping | Value stream map example | Best Value

- Value stream map example | Timeline Diagrams | Communication ...

- Types of Flowchart - Overview | Value - Stream Mapping for ...

- Value Stream Mapping | Value stream map example | Value Stream ...

- Value stream mapping diagram | Value Stream Analysis | What is ...

- Material Requisition Flowchart. Flowchart Examples | Value stream ...

- Value stream map example

- Value Stream Mapping

- Management | Timeline Diagrams | Value stream map example ...

- Timeline Diagrams | Value stream map example | Value stream ...

- Value Stream Mapping

- Value stream mapping diagram | Swim lane process mapping ...