Value Stream Mapping Template

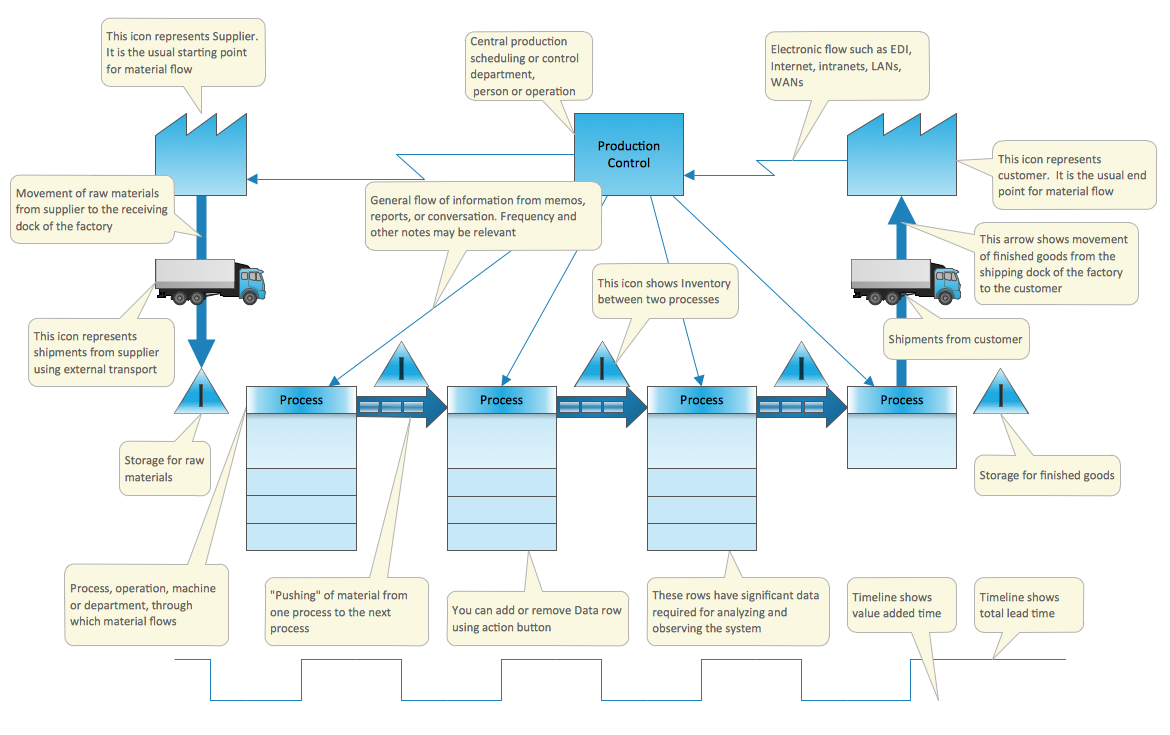

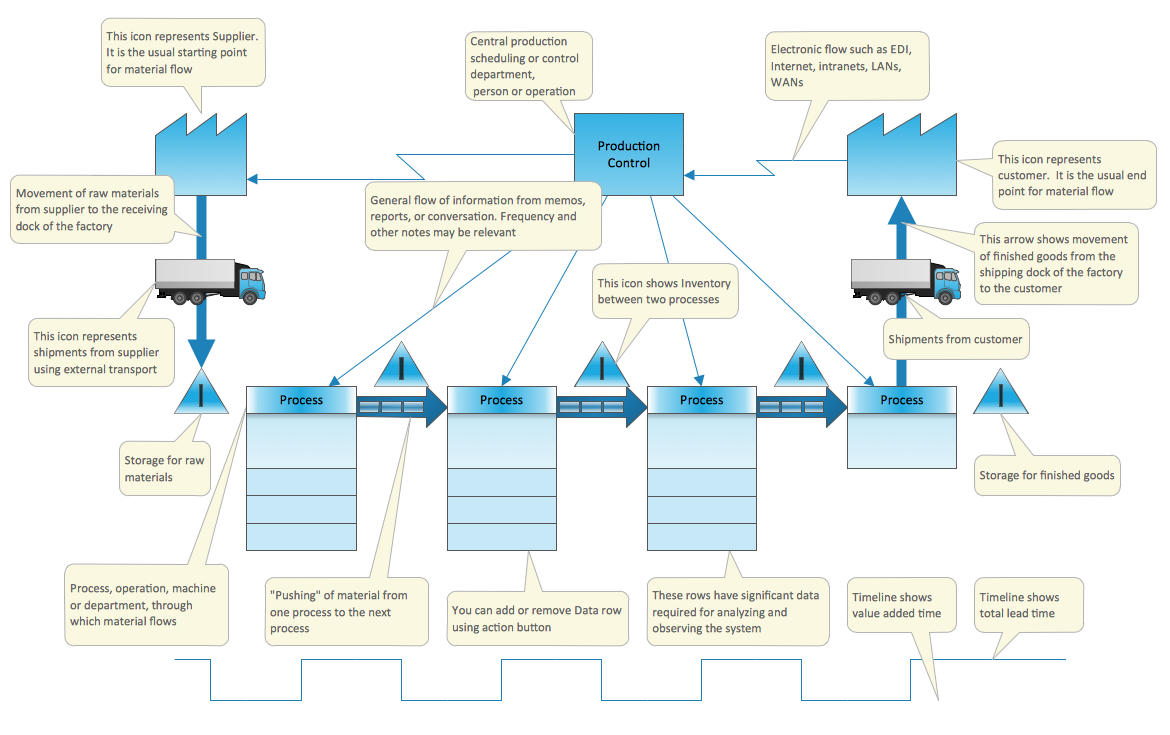

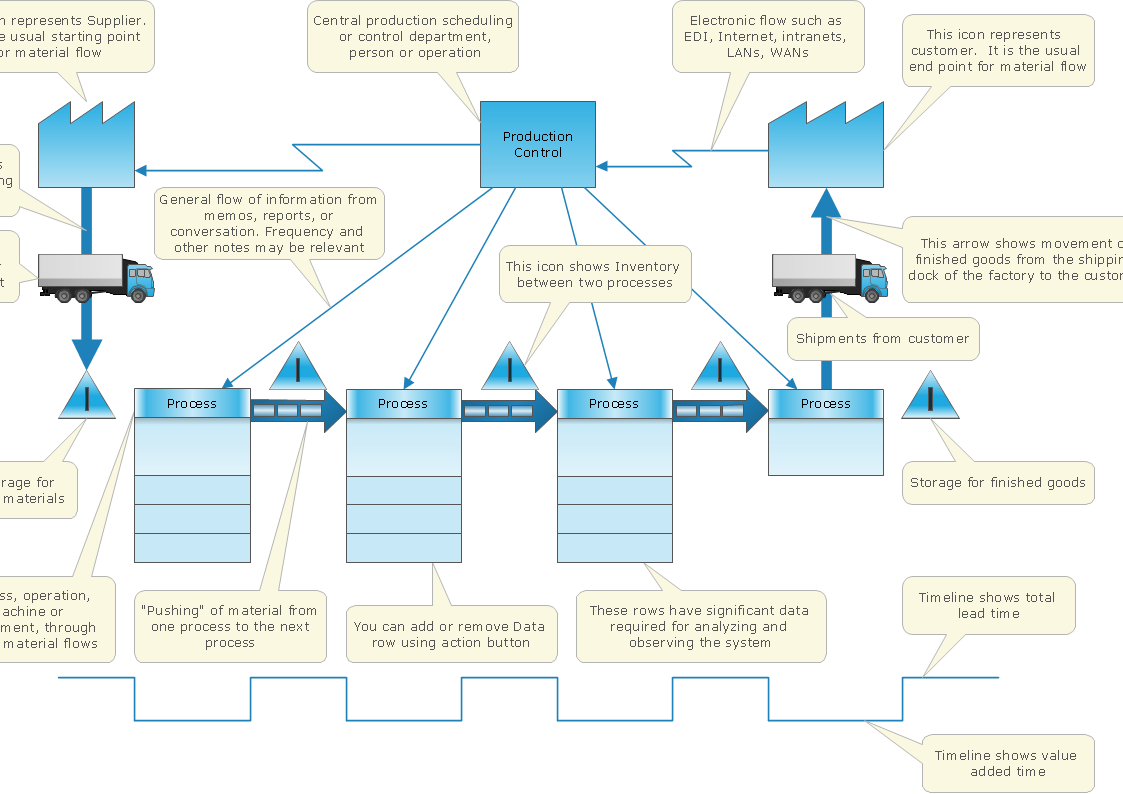

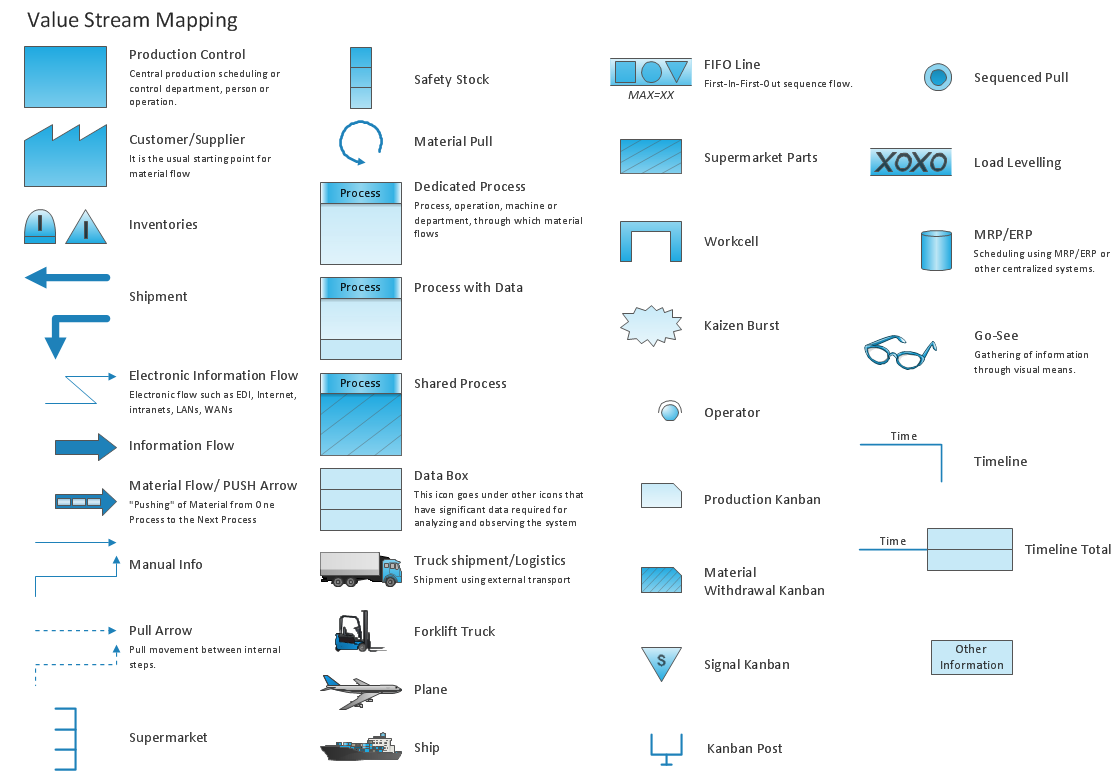

Use ConceptDraw PRO extended with Value Stream Mapping solution for document processes with professional designed Value Stream Mapping template.Value Stream Mapping Symbols

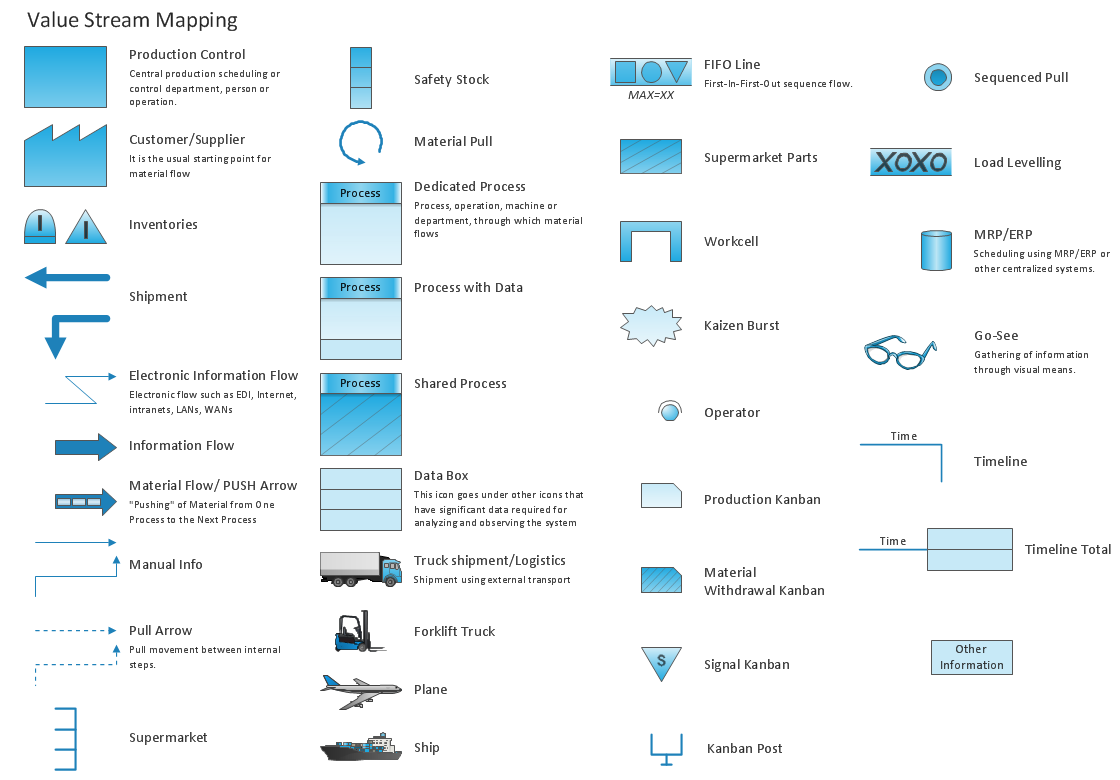

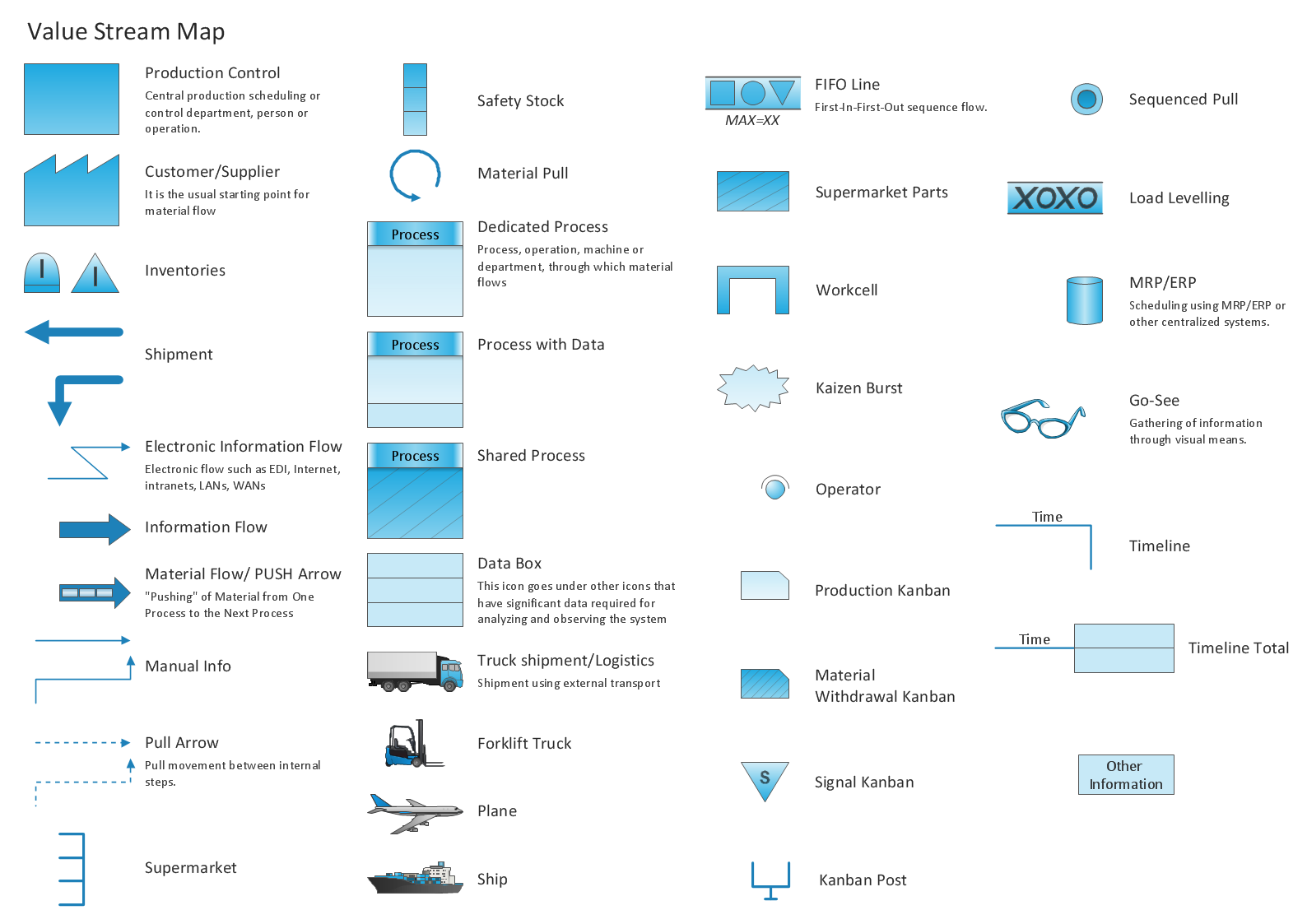

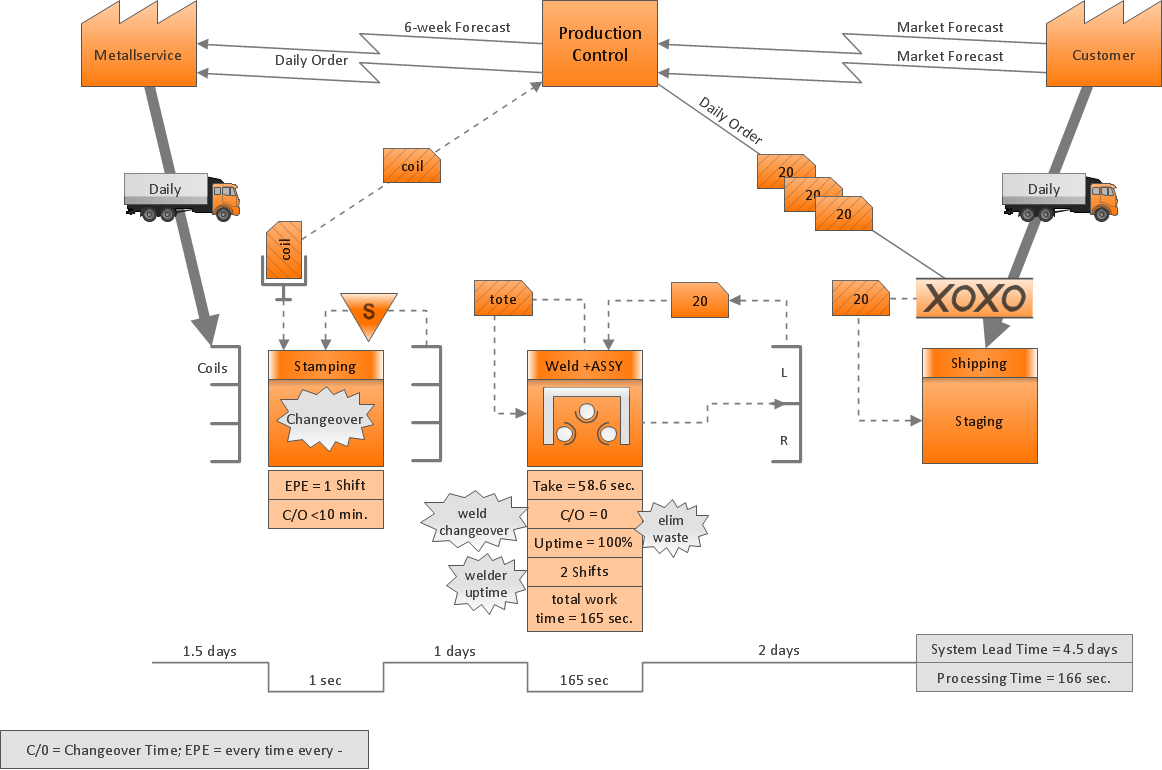

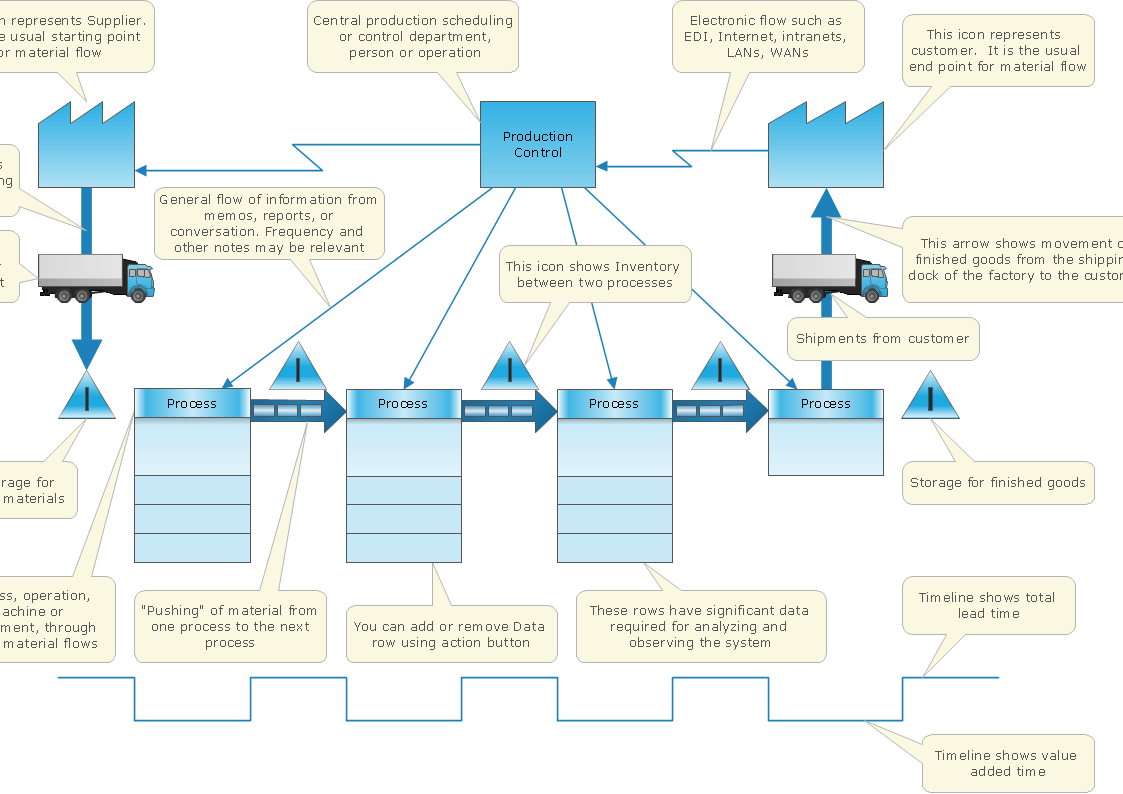

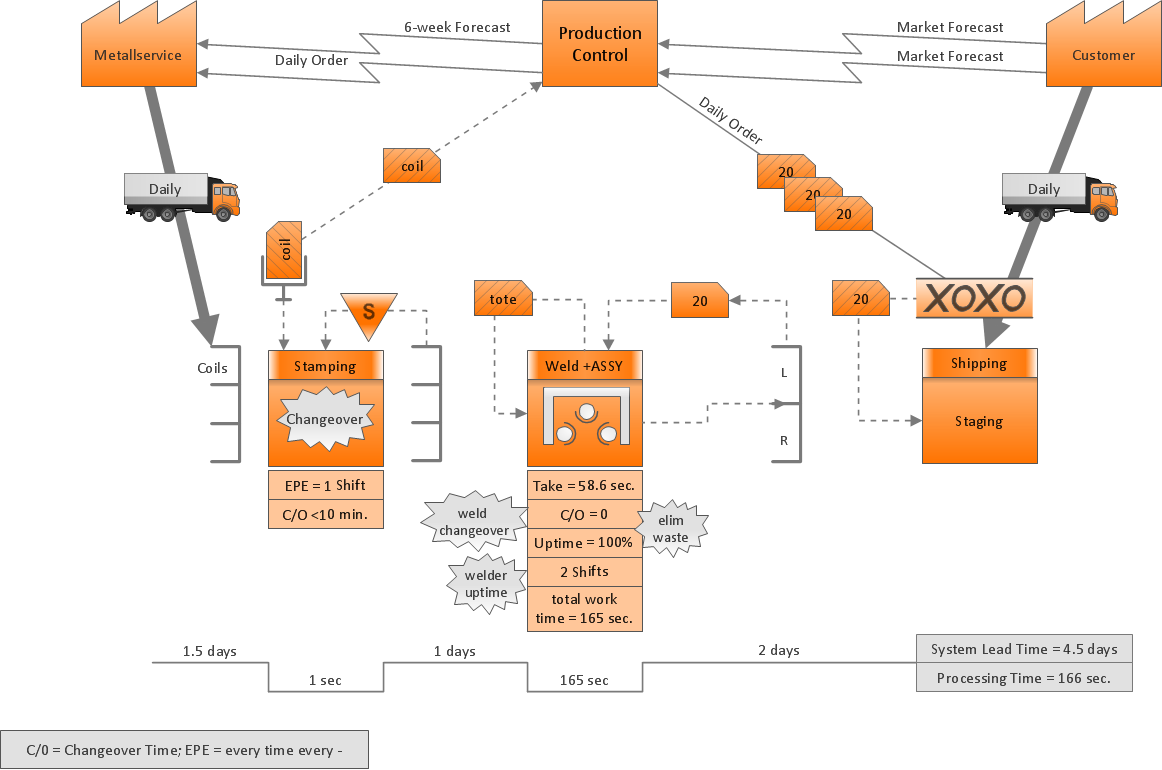

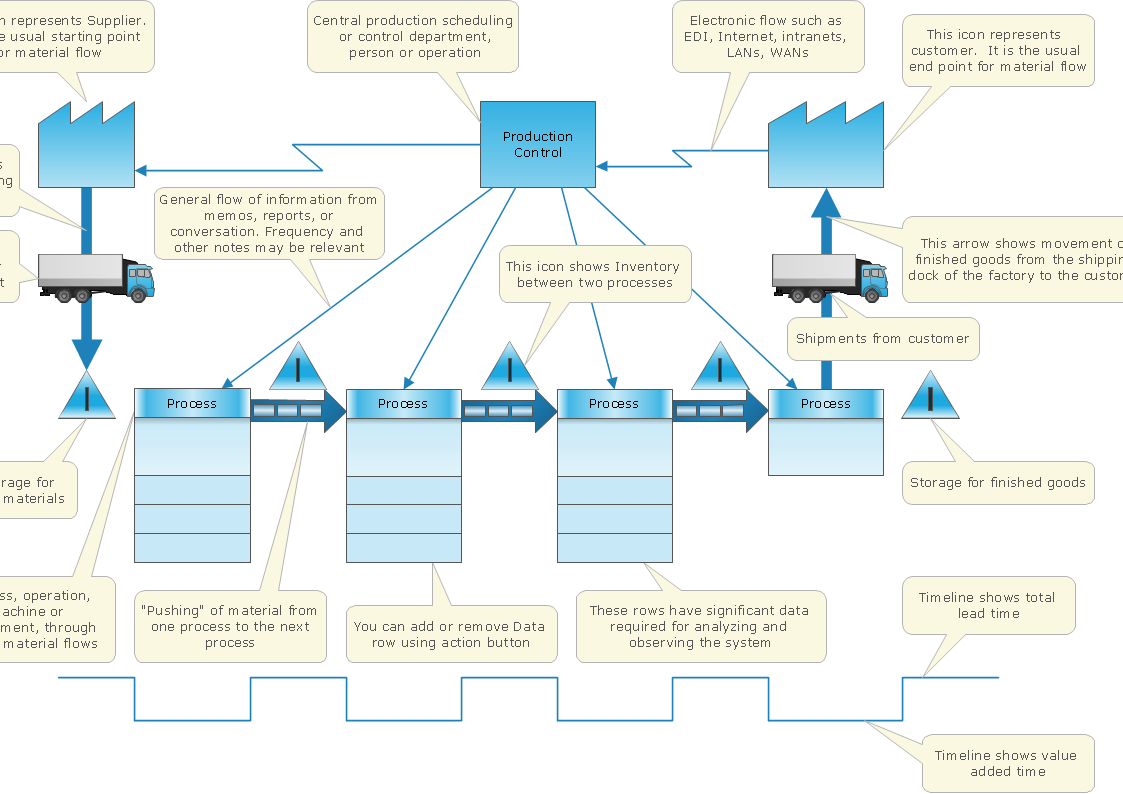

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.Learn how to create a current state value stream map

Value Stream Mapping solution extends ConceptDraw PRO software with templates, samples and vector shapes for drawing the current state value stream maps.VSM

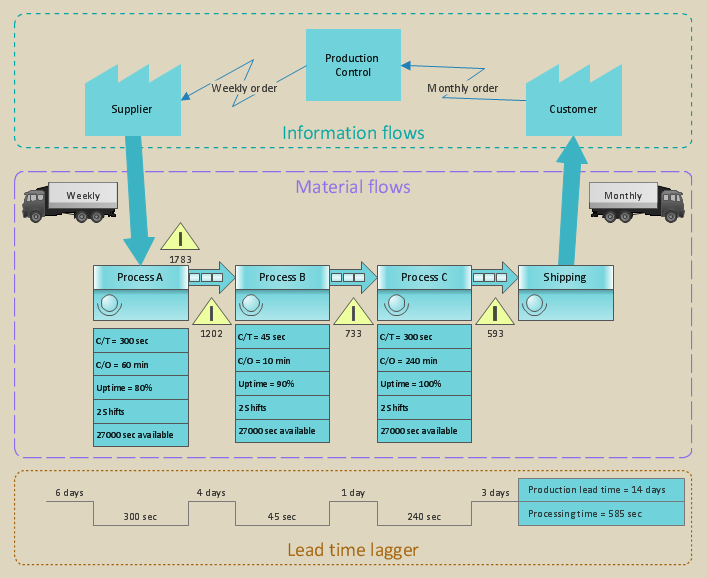

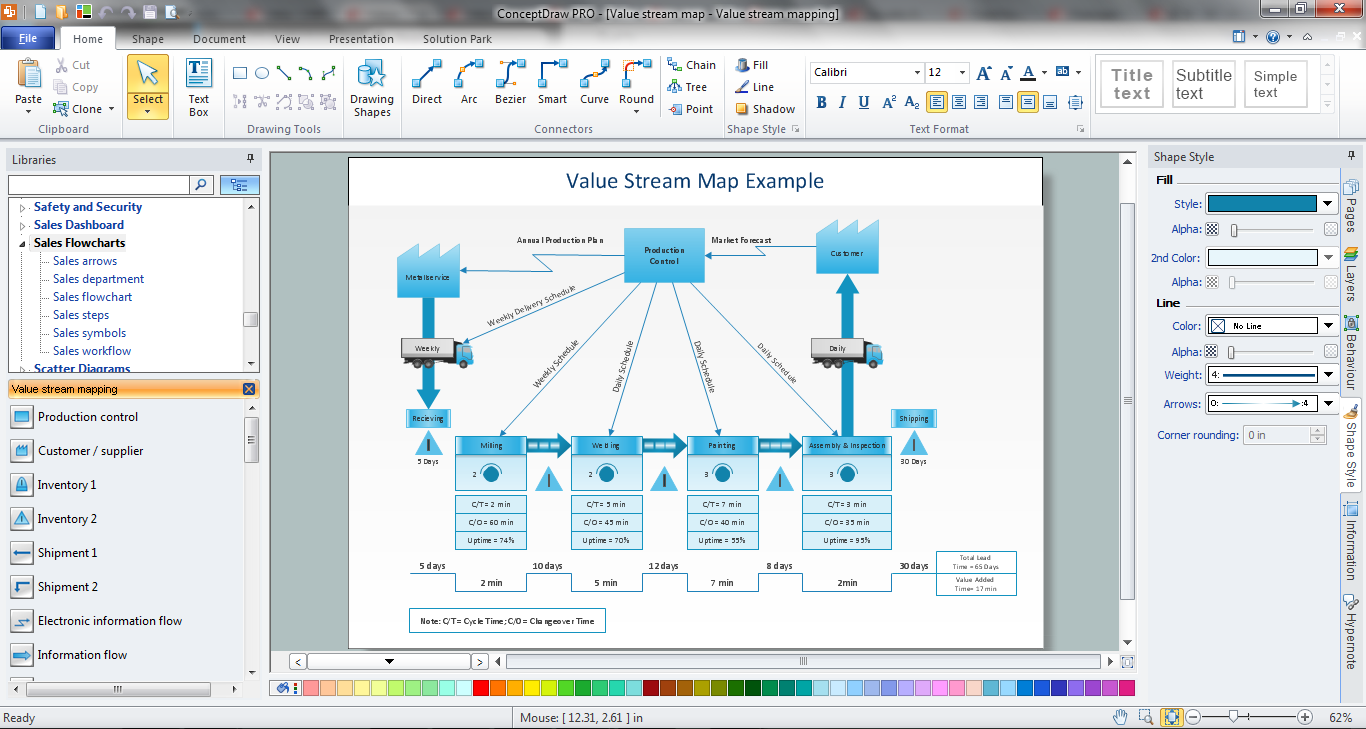

Value stream mapping is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer. ConceptDraw PRO diagramming and vector drawing software extended with Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park is effective for implementation a value stream mapping (VSM) process and for creating Value Stream Maps.Value Stream Map

ConceptDraw PRO diagramming and vector drawing software offers a powerful Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park which contains a set of useful tools for easy drawing Value Stream Map of any complexity.Value Stream Mapping

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product/service to customers. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes in any organization.Value Stream Mapping Software

ConceptDraw PRO is a best Value Stream Mapping software. The graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes in any organization.Best Value Stream Mapping mac Software

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Value Stream Mapping Examples

ConceptDraw PRO diagramming and vector drawing software supplied with Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park is ideal for drawing Value Stream Maps and includes variety of value stream mapping examples.How To create Value Stream Map (VSM)

Value Stream Map template helps you to create VSM diagrams using ConceptDraw PRO software.Create a Value Stream Map Rapidly

The Value Stream Mapping solution from ConceptDraw Solution Park extends ConceptDraw PRO software with a new library that contains vector objects, samples and templates.Lean Value Stream

ConceptDraw Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process.Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Lean Manufacturing Diagrams

The Value Stream Mapping solution continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes of Lean Manufacturing.Value Stream Mapping and Analysis

Value Stream Maps are used in lean methodology for analysis of manufacturing process and identification of the improvement opportunities.- Lean Manufacturing Current State Map Template

- Value Stream Mapping Template | Learn how to create a current ...

- Current State Value Stream Map Template

- Value Stream Mapping

- Learn how to create a current state value stream map | Best Value ...

- Value Stream Mapping Template

- Learn how to create a current state value stream map | Geo Map ...

- Free Value Stream Mapping For Mac

- | VSM Template | Value Stream Mapping Template | Vsm Template

- Value Stream Mapping Icons | Learn how to create a current state ...

- Learn how to create a current state value stream map | Value Stream ...

- Value Stream Mapping | Value Stream Mapping Template | Value ...

- Good Software For Value Stream Mapping On Mac

- Use Microsoft Project For Value Stream Mapping

- Value Stream & Process Flow Diagramming Software | Value stream ...

- Value Stream Mapping Template Visio

- Process Improvement Value Stream Mapping

- Value Stream Mapping Template

- Value Stream Process Mapping Template

- Value Stream Mapping Symbols | Value Stream Mapping Template ...