HelpDesk

How to Create a VSM Diagram Using ConceptDraw Value Stream Mapping Solution

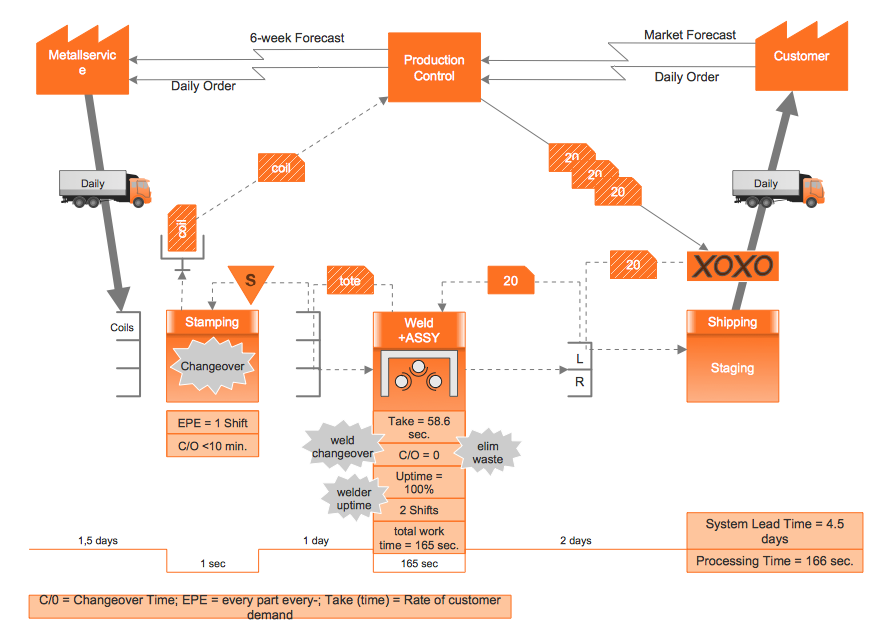

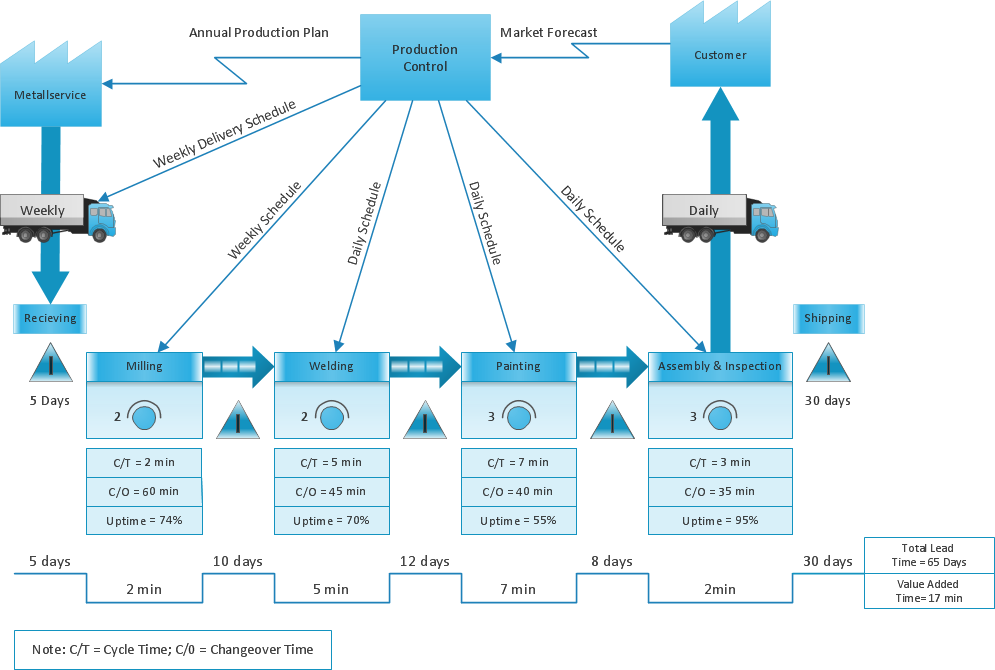

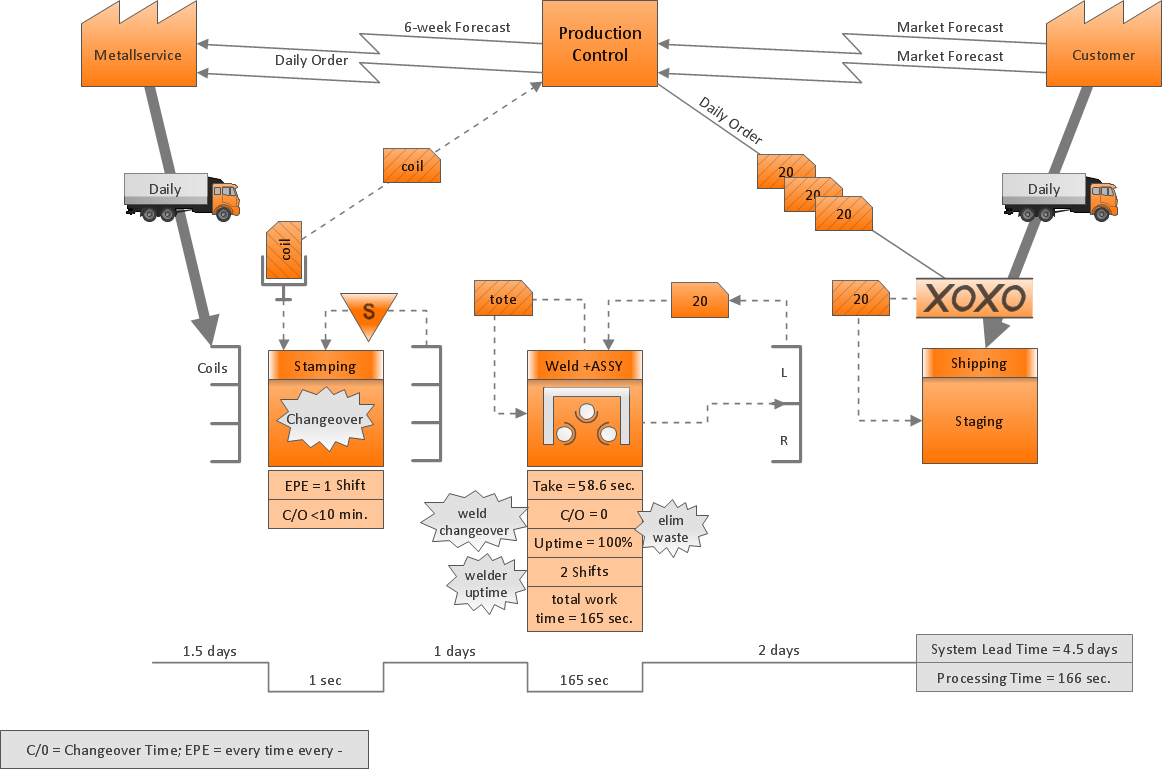

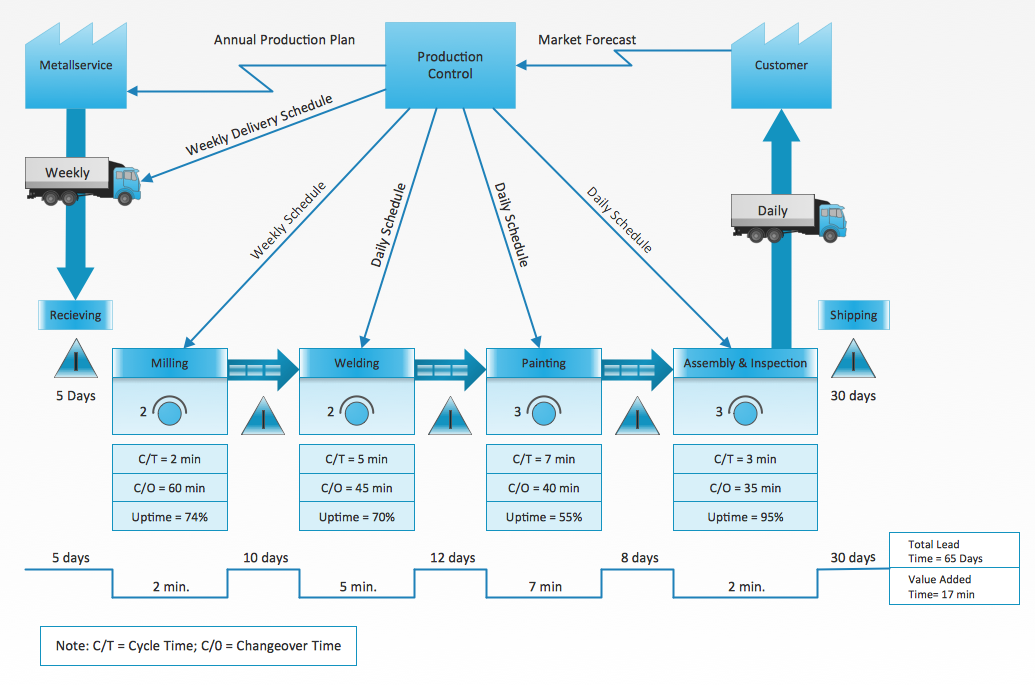

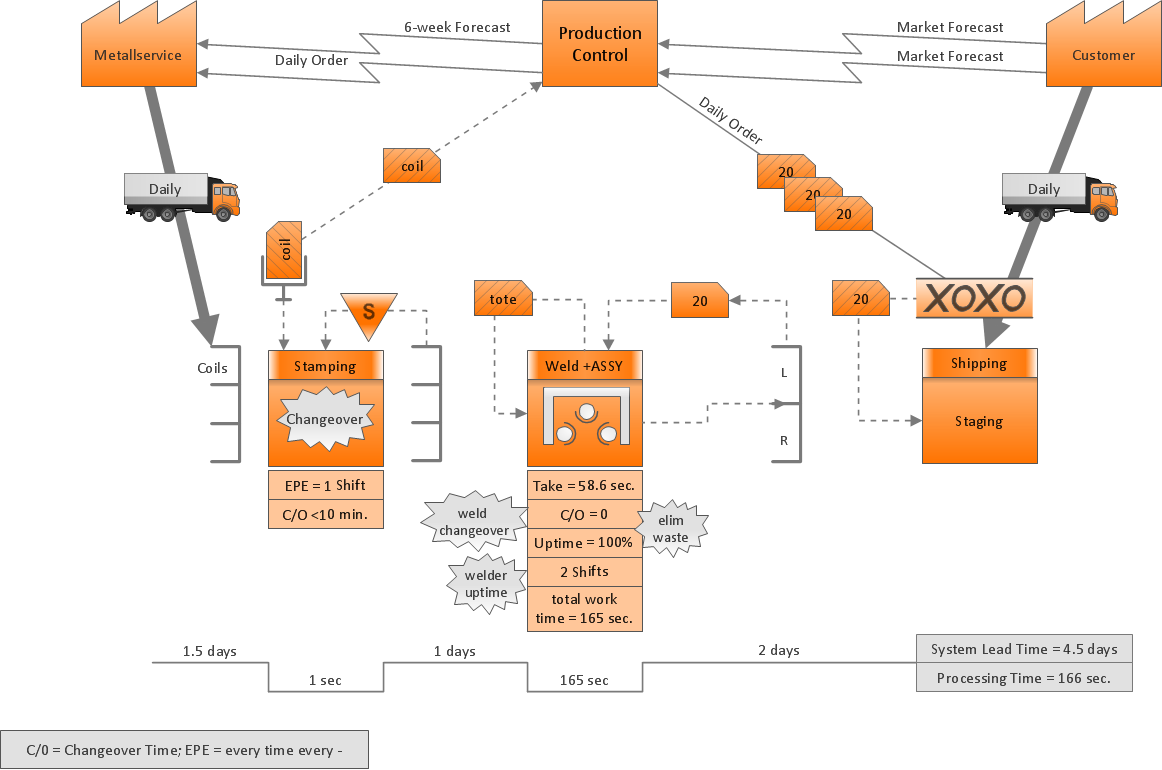

Value Stream Mapping is a Lean Manufacturing tool that uses a flow diagram to document in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value Stream Mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Many organizations use value stream mapping as a key portion of their lean efforts. Value Stream Maps are used to analyze and design the flow of materials and information required to bring a product or service to a consumer. You can create a Value Stream Mapping flowchart using ConceptDraw PRO tools.

Value Stream Mapping

Value Stream Mapping

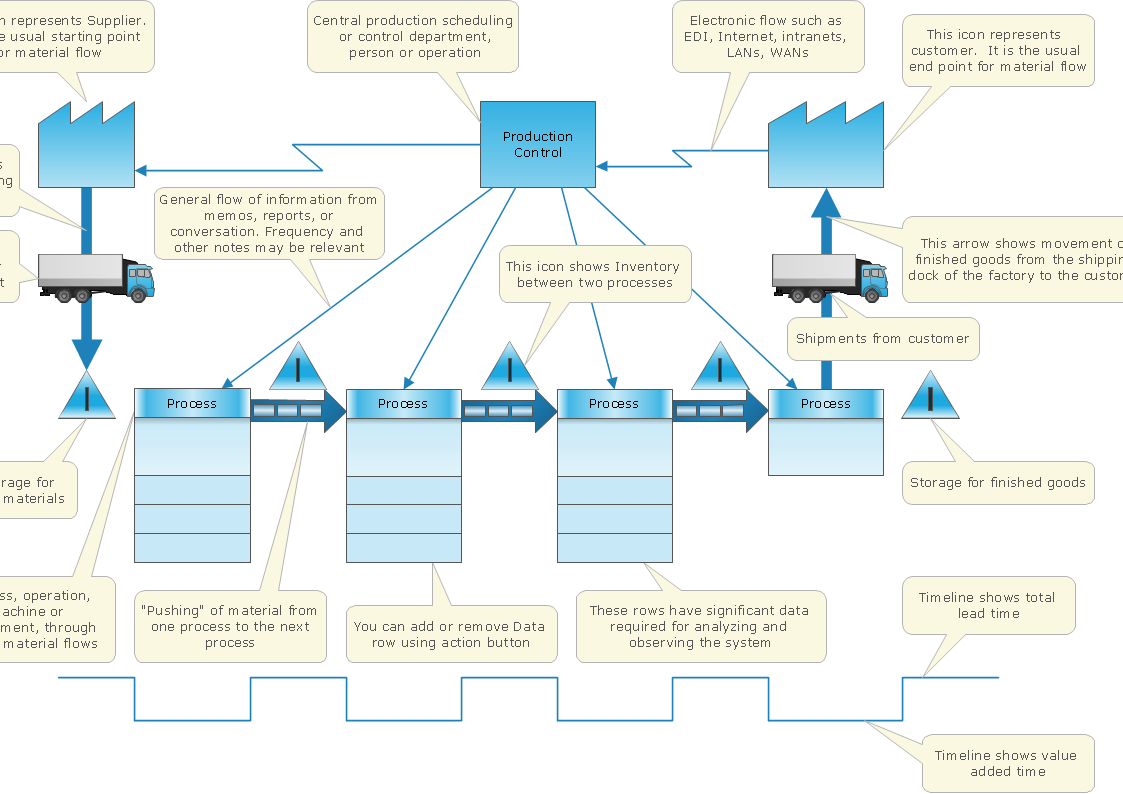

Value stream mapping solution extends ConceptDraw PRO software with templates, samples and vector stencils for drawing the Value Stream Maps (VSM) in lean manufacturing practice.

Lean Manufacturing Diagrams

The Value Stream Mapping solution continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes of Lean Manufacturing.Best Value Stream Mapping mac Software

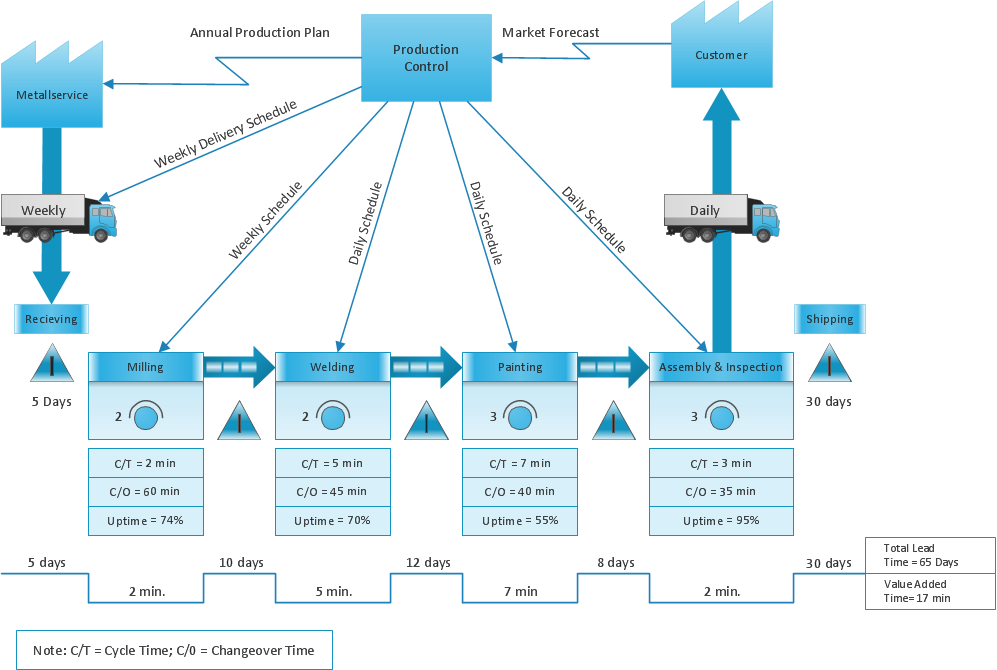

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Value Stream Mapping and Analysis

Value Stream Maps are used in lean methodology for analysis of manufacturing process and identification of the improvement opportunities.What is Value Stream Mapping?

Value stream maps (VSM) are an essential tool for organizations applying Lean methods.Value Stream Mapping for the Lean Office

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process.Value Stream Diagram

The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool.Value Stream Mapping Template

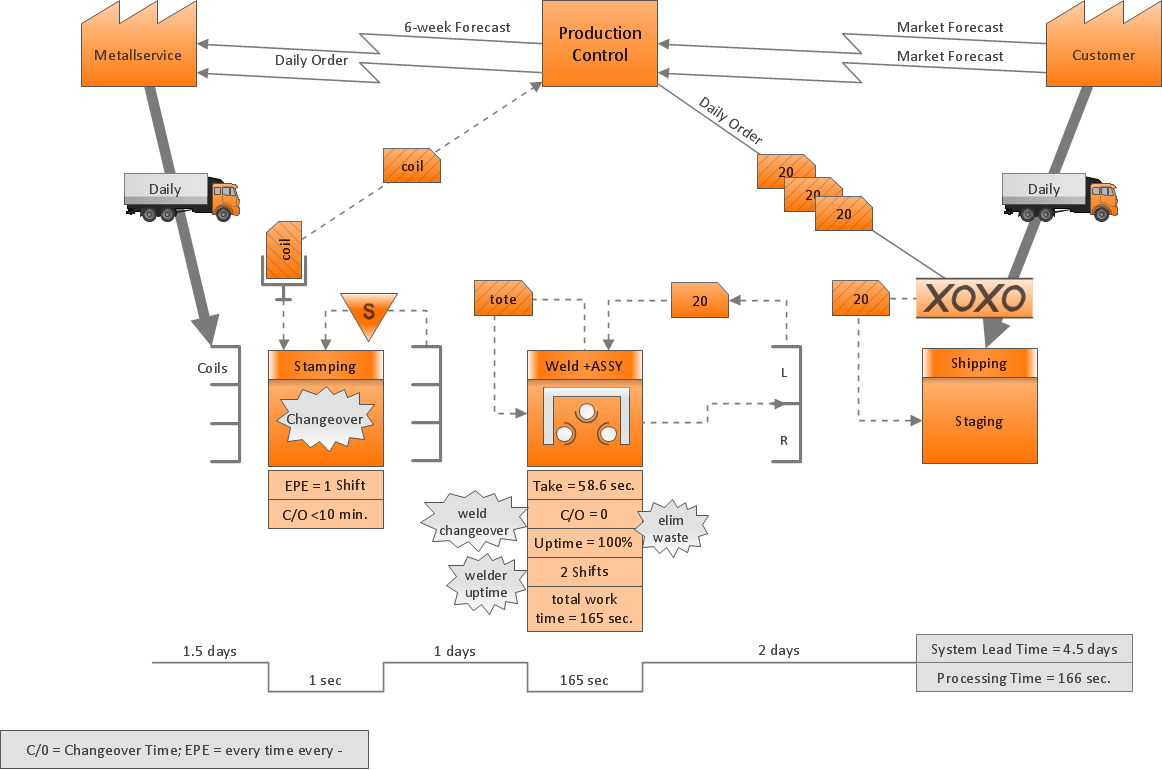

Use ConceptDraw PRO extended with Value Stream Mapping solution for document processes with professional designed Value Stream Mapping template.Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Learn how to create a current state value stream map

Value Stream Mapping solution extends ConceptDraw PRO software with templates, samples and vector shapes for drawing the current state value stream maps.Value Stream Mapping Icons

The library with 40 vector stencils is included in the ConceptDraw Value Stream Mapping solution.Value Stream Mapping Presentations

Users can create Value Stream Mapping Presentations using presentation mode in ConceptDraw PRO.Lean Value Stream Map

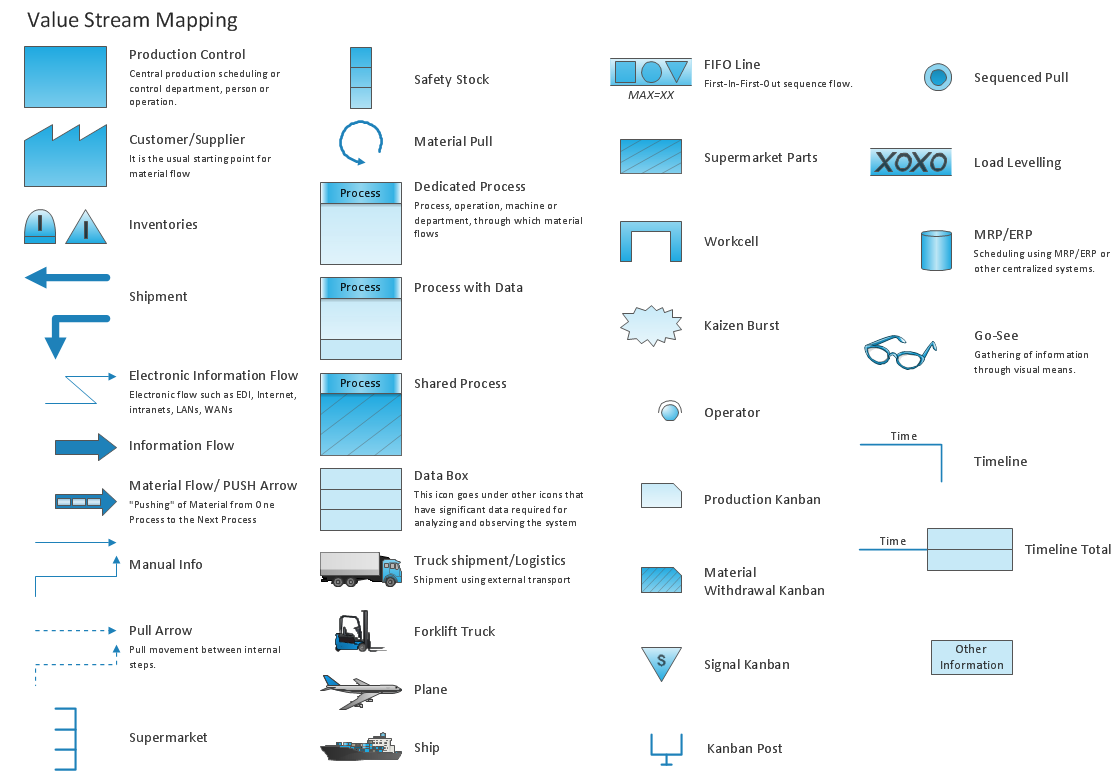

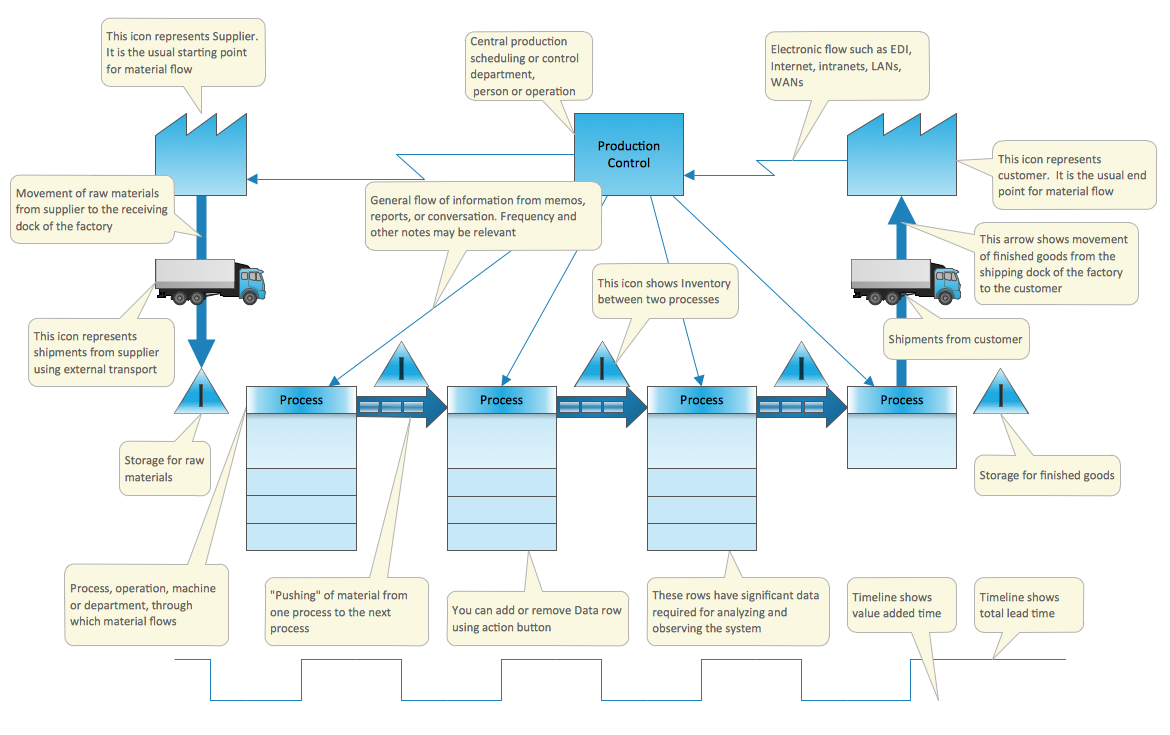

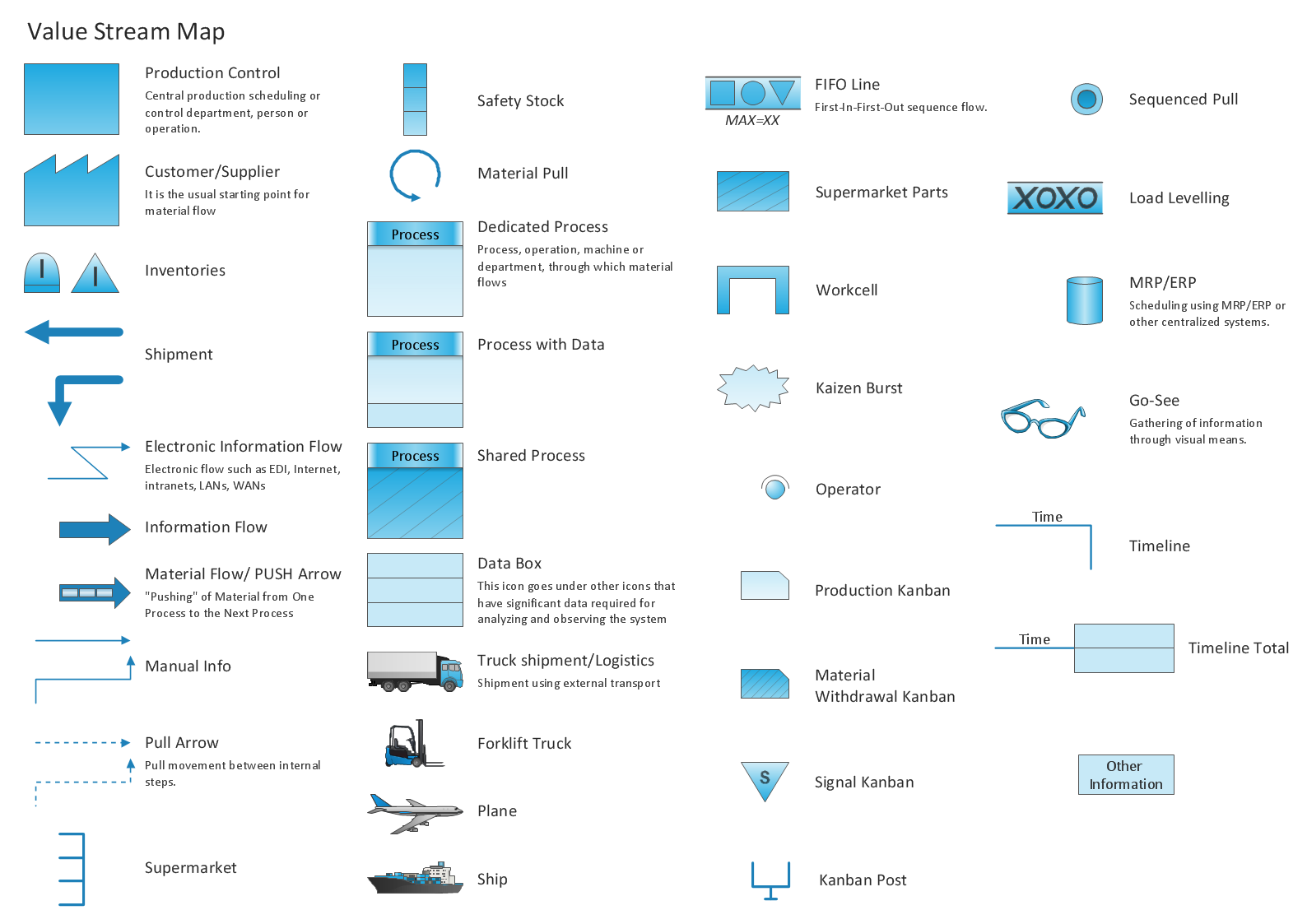

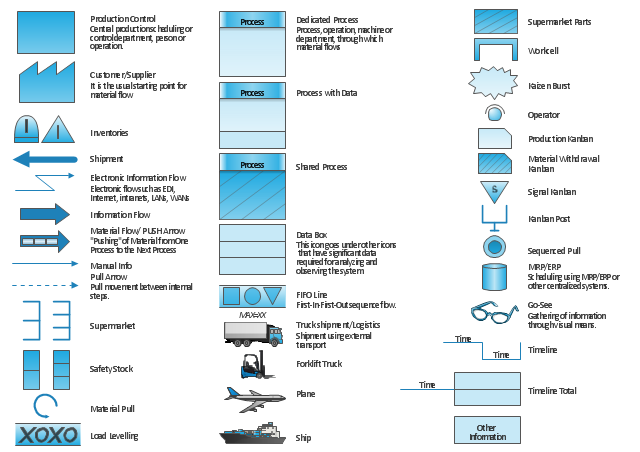

Lean Manufacturing tool is a new Value Stream Mapping solution found in the ConceptDraw Solution Park."Value stream mapping usually employs standard symbols to represent items and processes, therefore knowledge of these symbols is essential to correctly interpret the production system problems." [Value stream mapping. Wikipedia]

The vector stencils library Value stream mapping contains 43 symbols for drawing the value stream mapping diagrams using the ConceptDraw PRO diagramming and vector drawing software.

The example "Design elements - Value stream mapping diagram" is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

The vector stencils library Value stream mapping contains 43 symbols for drawing the value stream mapping diagrams using the ConceptDraw PRO diagramming and vector drawing software.

The example "Design elements - Value stream mapping diagram" is included in the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

- Lean Manufacturing Diagrams | How Do Fishbone Diagrams Solve ...

- What is Value Stream Mapping ? | Total Quality Management Value ...

- Value Stream Mapping Symbols

- How Do Fishbone Diagrams Solve Manufacturing Problems | TQM ...

- Lean Manufacturing Diagrams | Value Stream Mapping Icons ...

- How Do Fishbone Diagrams Solve Manufacturing Problems | Value ...

- Vsm Sample

- The Purpose Of Vsm Is To And Eliminate Waste

- Payroll process - Swim lane process mapping diagram | Design ...

- ConceptDraw Solution Park | Business Process Workflow Diagrams ...

- The Lean Enterprise Value Stream Mapping | Quality Engineering ...

- Value Stream Mapping for the Lean Office | Lean Manufacturing ...

- Lean Manufacturing Diagrams | Value Stream Mapping | Types of ...

- Process Flowchart | How to Create a VSM Diagram Using ...

- VSM Template | Quality Mind Map Solution | Quality Engineering ...

- Value Stream Mapping | How to Create a VSM Diagram Using ...

- What is Value Stream Mapping ?

- Value Stream Mapping | Value Stream Diagram | How to Create a ...

- Lean Manufacturing Diagrams | Value-Stream Mapping for ...