Value-Stream Mapping for Manufacturing

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Create a Value Stream Map

Use ConceptDraw PRO software extended with Value Stream Mapping solution to create your own VSM diagrams.Learn how to create a current state value stream map

Value Stream Mapping solution extends ConceptDraw PRO software with templates, samples and vector shapes for drawing the current state value stream maps.Value Stream Mapping for the Lean Office

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process.The Value Stream Mapping Process

ConceptDraw Value Stream Maps are used in lean manufacturing methodology to analyze and identify the process improvement opportunities that are available.Value Stream & Process Flow Diagramming Software

Value Stream & Process Flow Diagramming Software is a very popular Lean Manufacturing tool that allows to see and visualize in details the company's processes and current state, the flow of material and information, and thus gives the possibility to analyze the efficiency of company's processes and then develop improved processes. Value stream maps are also a good way to define the steps that do not add value to the end product, in other words waste in a company's processes.Value Stream Maps Visualize

ConceptDraw Value Stream Maps visualize for a manufacturing plant the material and information flow.Value Stream Mapping and Analysis

Value Stream Maps are used in lean methodology for analysis of manufacturing process and identification of the improvement opportunities."Value Stream Map (VSM)

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

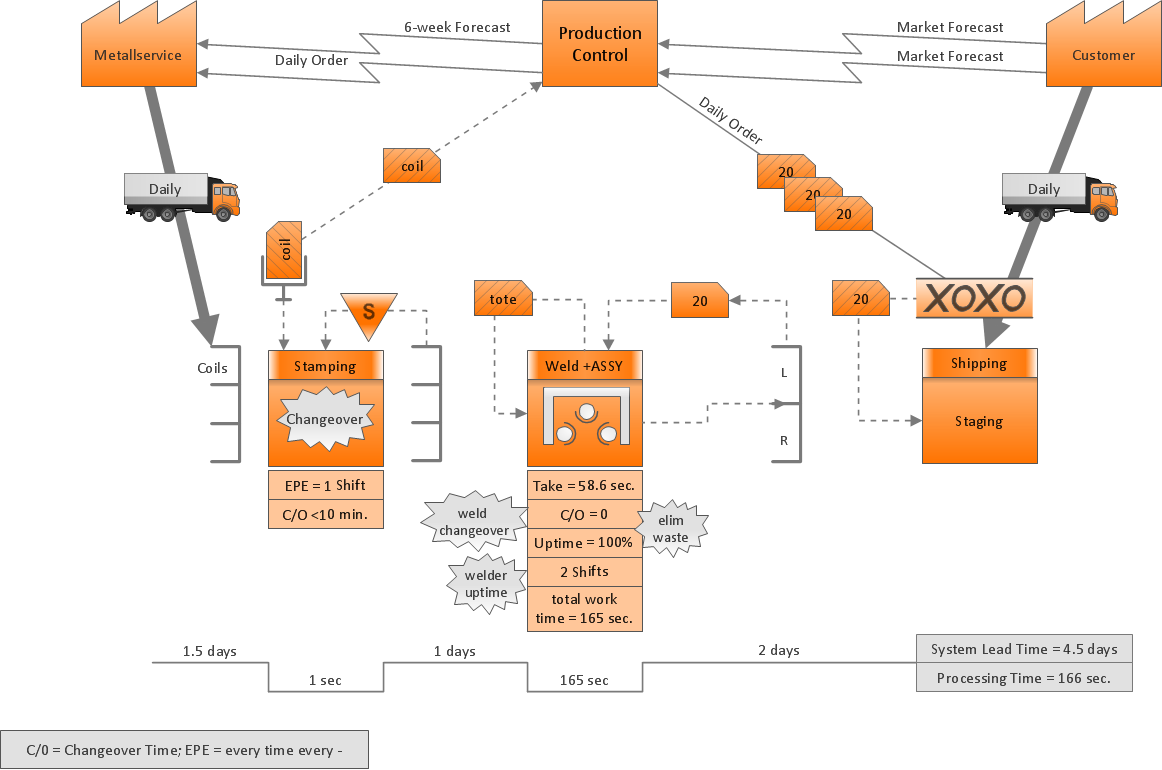

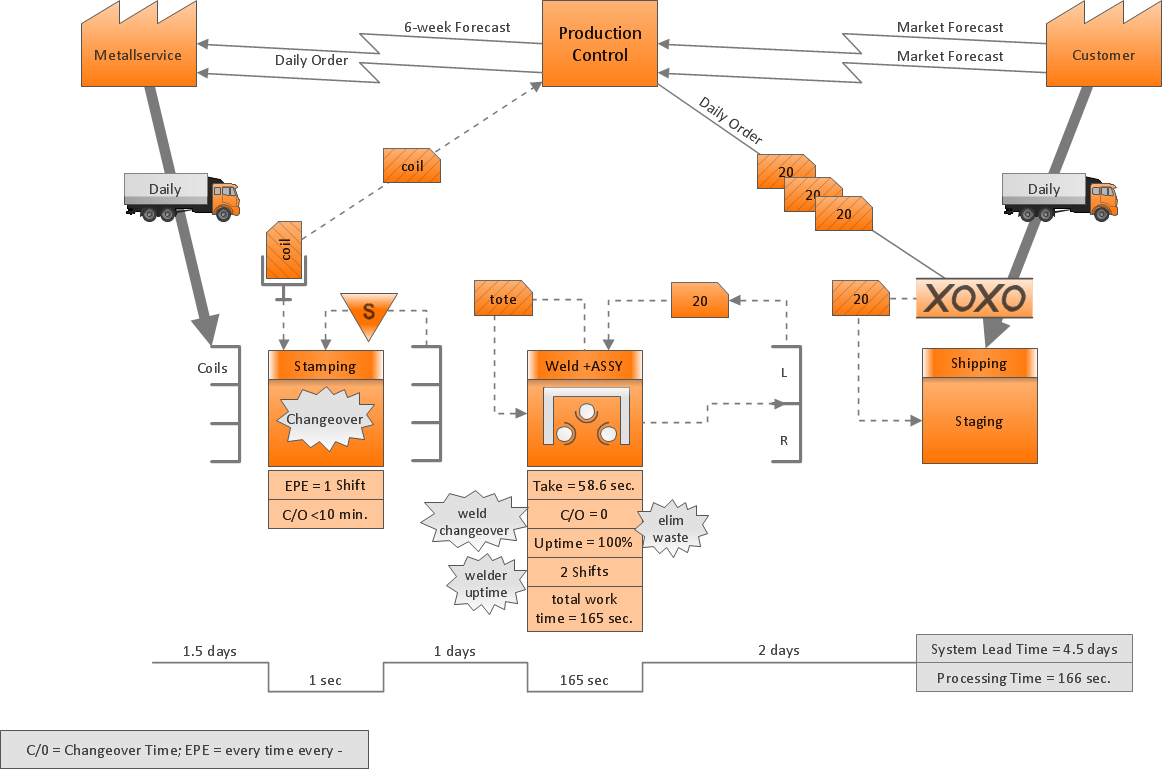

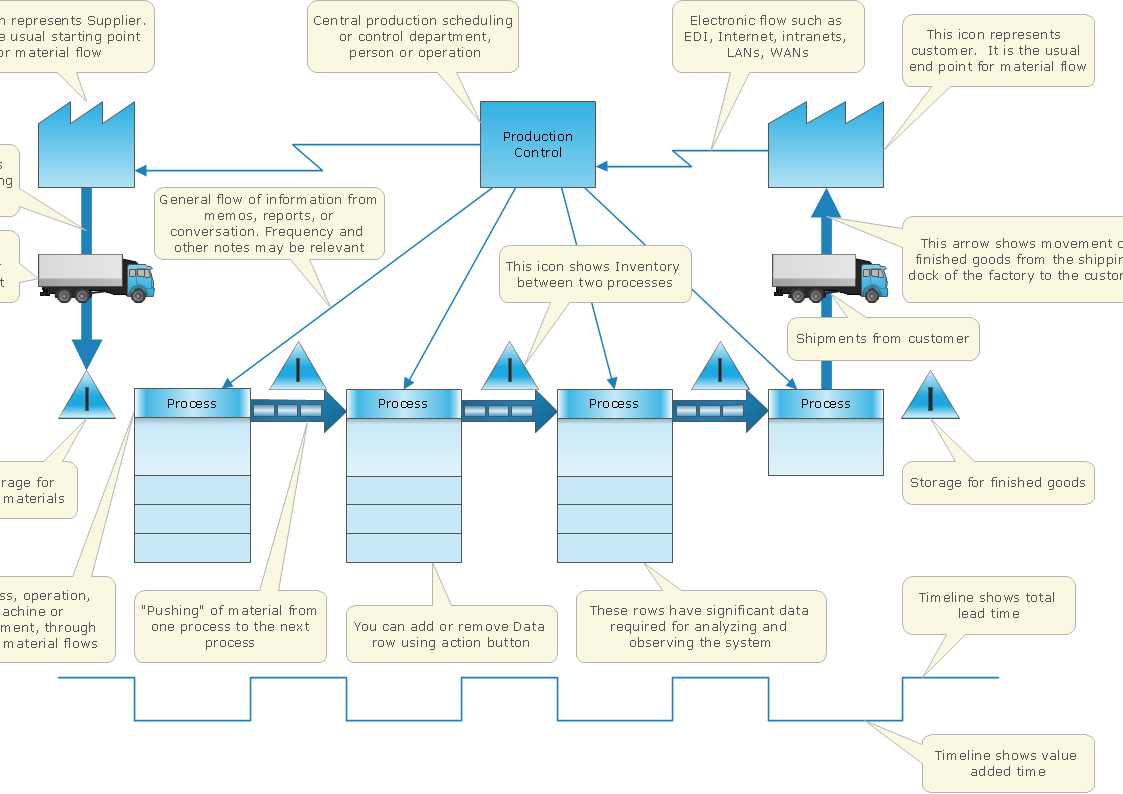

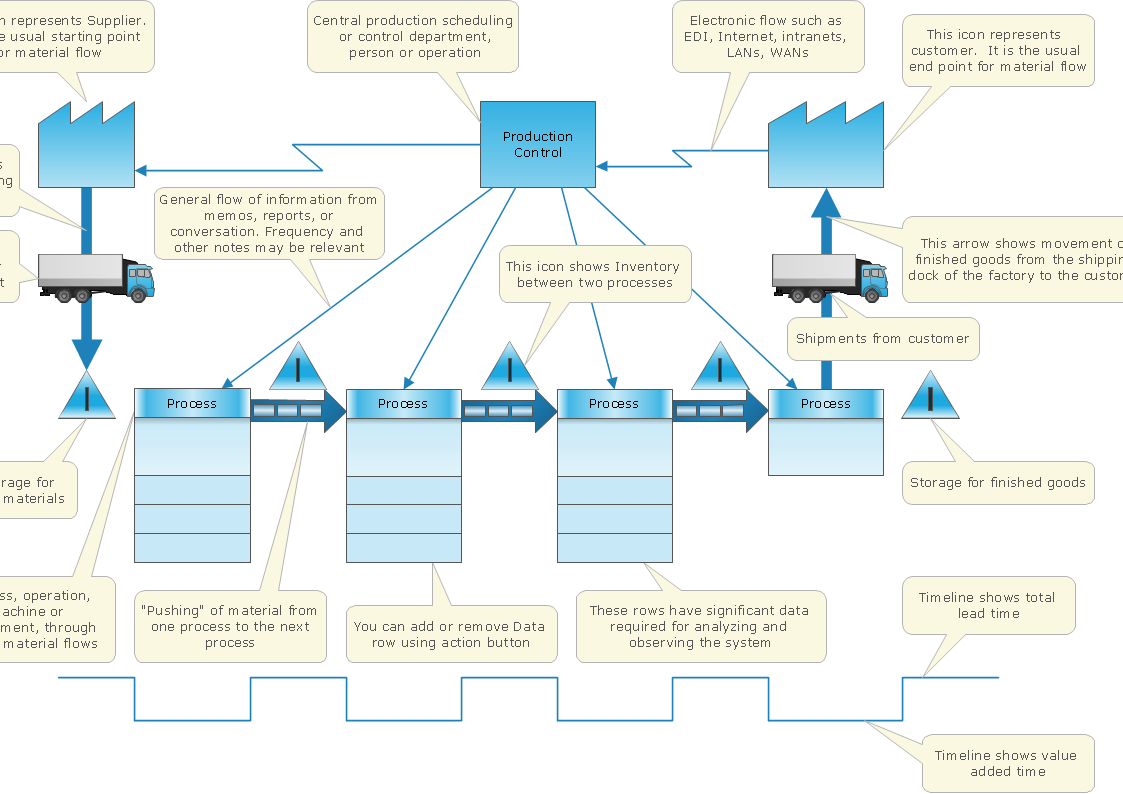

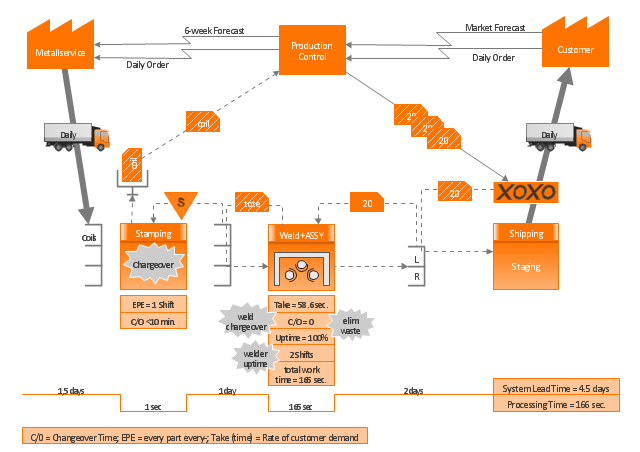

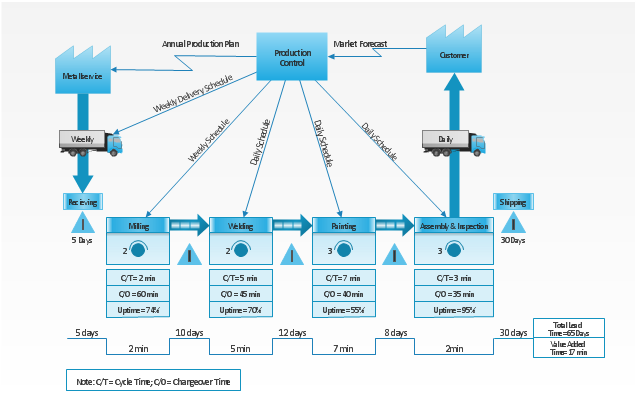

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

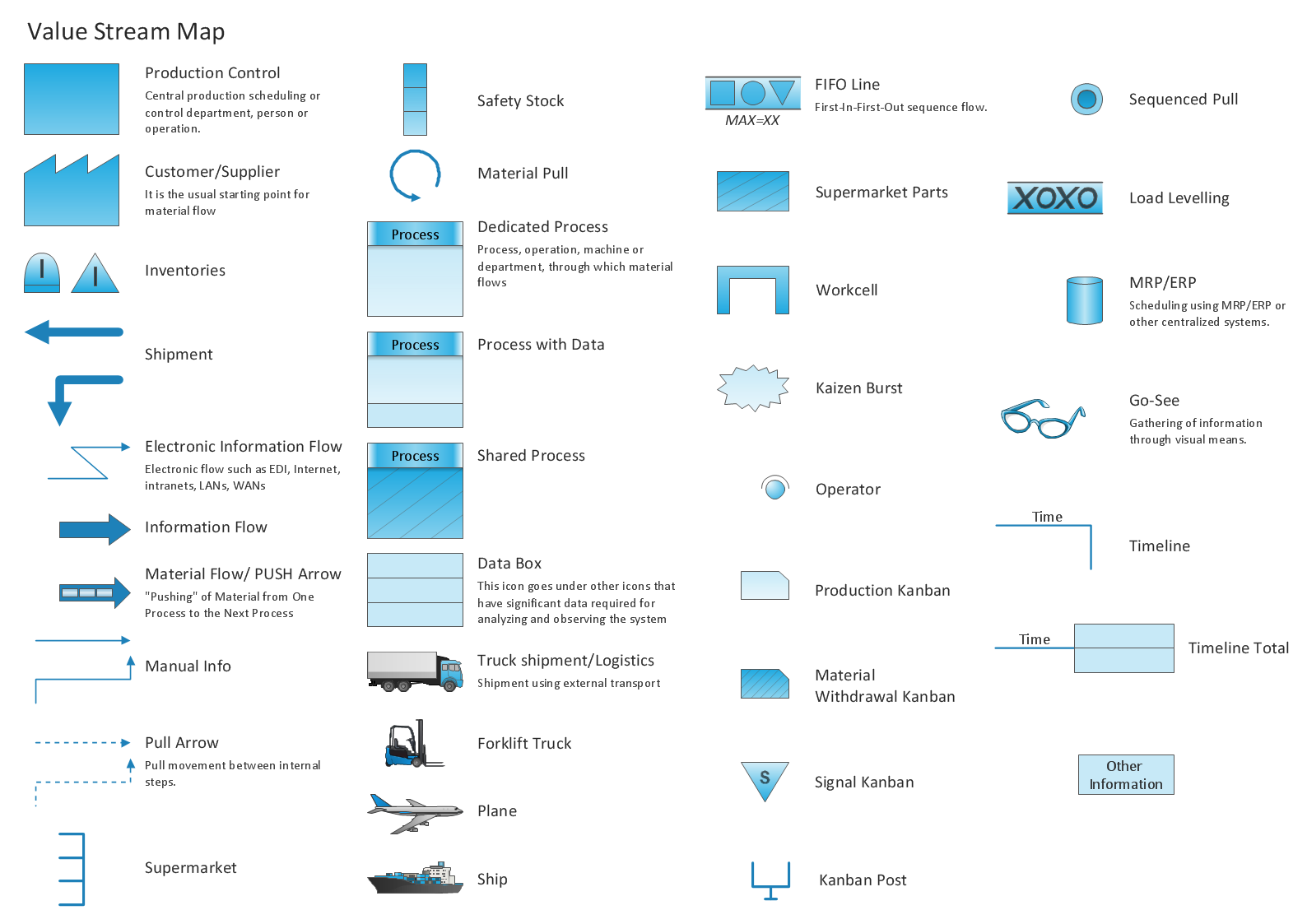

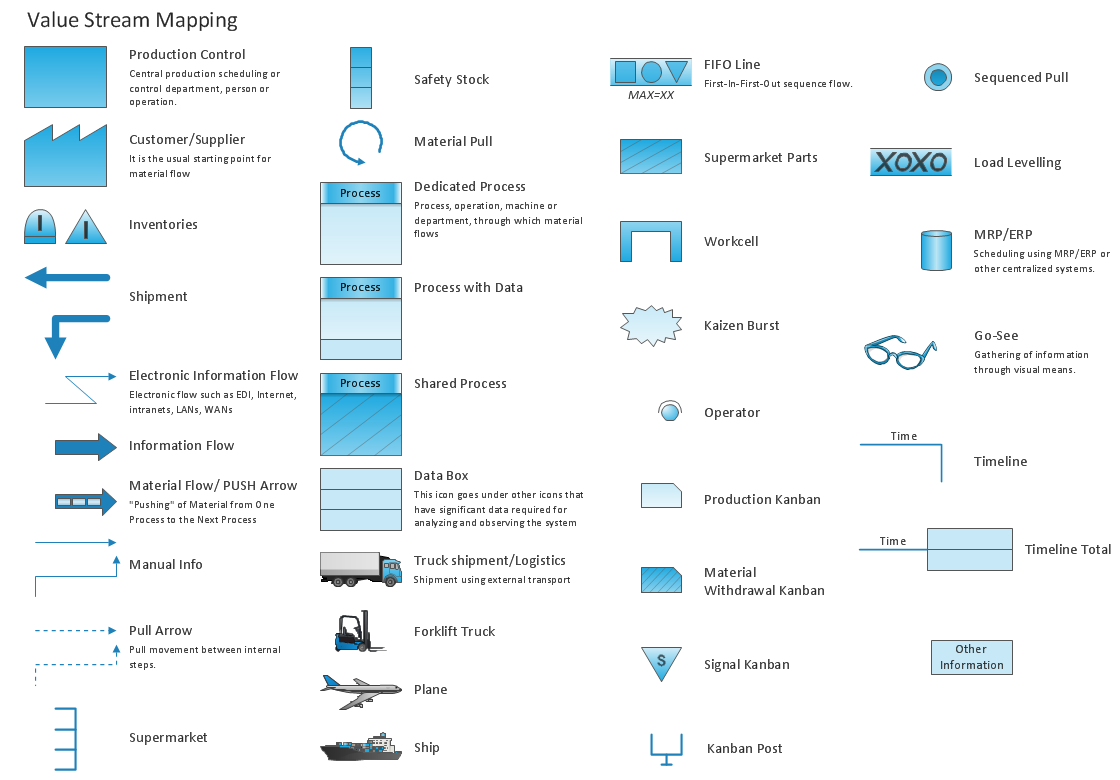

"Value Stream Mapping (VSM):

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

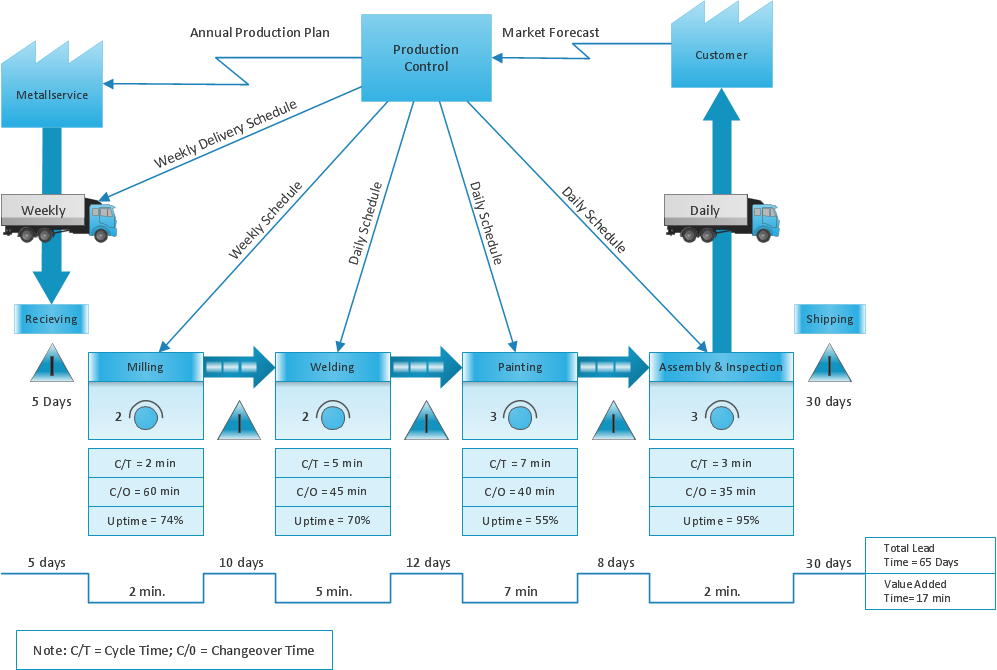

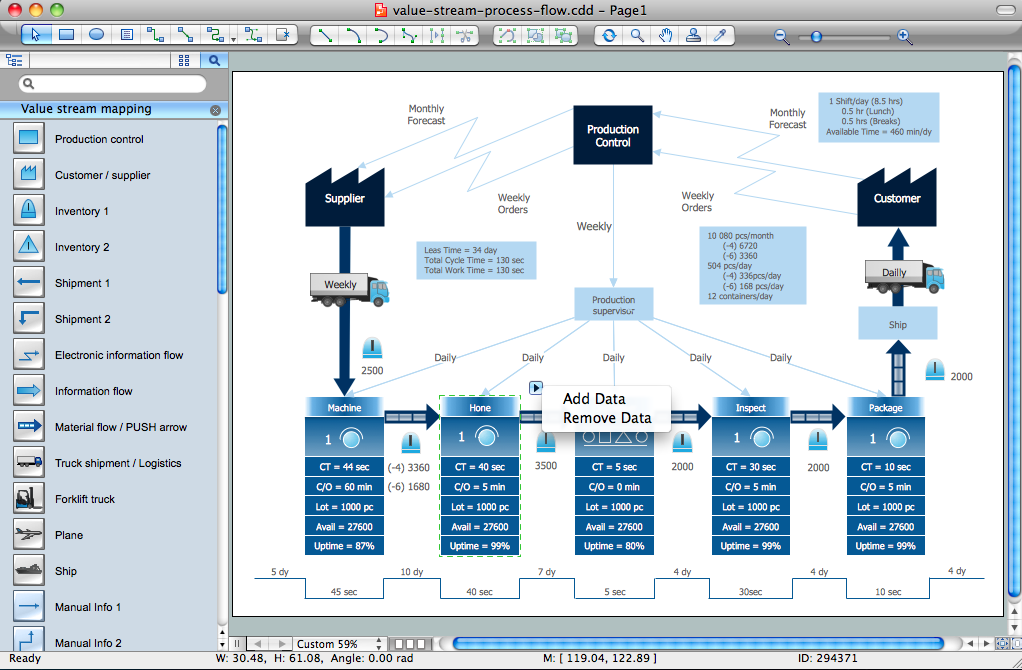

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

– Special type of flow chart that uses symbols known as "the language of Lean" to depict and improve the flow of inventory information. ...

Value Stream Mapping ...

Provide optimum value to the customer through a complete value creation process with minimum waste in:

– Design (concept to customer);

– Design (concept to customer);

– Build (order to delivery);

– Sustain (in-use through life cycle to service)." [courses.washington.edu/ ie337/ Value_ Stream_ Mapping.pdf]

This sample Value Stream Map shows how customer value is created in the steps of manufacturing, production control, and shipping processes.

This VSM example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

- Identification Of Waste Through Vsm Diagram

- Lean Manufacturing Diagrams | Value Stream Mapping | Value ...

- Lean Manufacturing Diagrams | Value Stream Mapping for the Lean ...

- Lean Manufacturing Chart

- Lean Manufacturing Diagrams | Value Stream Mapping for the Lean ...

- Lean Manufacturing Diagrams | Value Stream Mapping | Types of ...

- Value Stream Mapping | Value-Stream Mapping for Manufacturing

- Fishbone Diagram | Lean Manufacturing Diagrams | Bar Diagrams ...

- Lean Value Stream Map | Value-Stream Mapping for Manufacturing

- Value Stream Mapping Shipping

- Value Stream Mapping | Value-Stream Mapping for Manufacturing

- Manufacturing 8 Ms fishbone diagram - Template | Data Flow ...

- Value Stream Mapping Production Control

- Process Flowchart | 4 Ms fishbone diagram - Production process ...

- Lean Manufacturing Current State Map Template

- Value Stream Mapping Symbols | Lean Manufacturing Diagrams ...

- Value Stream Mapping

- Value Stream Mapping | Value stream with ConceptDraw PRO | Best ...

- Value Stream Mapping | Quality Engineering Diagrams | Value ...

- Value stream map example