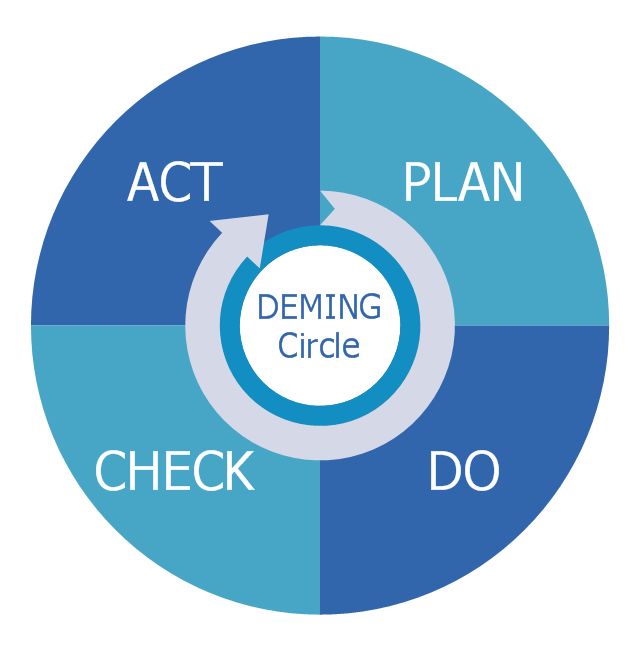

This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: Deming PDCA cycle.PNG. [commons.wikimedia.org/ wiki/ File:Deming_ PDCA_ cycle.PNG]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"The concept of PDCA is based on the scientific method, as developed from the work of Francis Bacon (Novum Organum, 1620). The scientific method can be written as "hypothesis"–"experiment"–"evaluation" or plan, do and check." [PDCA. Wikipedia]

The plan-do-check-act diagram example "Deming PDCA cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: Deming PDCA cycle.PNG. [commons.wikimedia.org/ wiki/ File:Deming_ PDCA_ cycle.PNG]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"The concept of PDCA is based on the scientific method, as developed from the work of Francis Bacon (Novum Organum, 1620). The scientific method can be written as "hypothesis"–"experiment"–"evaluation" or plan, do and check." [PDCA. Wikipedia]

The plan-do-check-act diagram example "Deming PDCA cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

This business infographic sample shows the plan–do–check–act cycle. It was designed on the base of the Wikimedia Commons file: PDCA-Cycle.png.

[commons.wikimedia.org/ wiki/ File:PDCA-Cycle.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA)." [PDCA. Wikipedia]

The business infographic example "PDCA cycle" was designed using ConceptDraw PRO diagramming and vector drawing software extended with the Business and Finance solution from Illustration area of ConceptDraw Solution Park.

[commons.wikimedia.org/ wiki/ File:PDCA-Cycle.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA)." [PDCA. Wikipedia]

The business infographic example "PDCA cycle" was designed using ConceptDraw PRO diagramming and vector drawing software extended with the Business and Finance solution from Illustration area of ConceptDraw Solution Park.

Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act (PDCA) solution extends the ConceptDraw DIAGRAM software with collection of samples and predesigned vector objects for easy visualization four stages of PDCA cycle, PDSA cycle, or Deming cycle, for illustration effective application of this method to the practical business tasks, for depiction the implementation of changes and solution the problems in business processes. Plan-Do-Check-Act (PDCA) solution helps to design professional-looking and attractive Plan Do Study Act diagrams, PDCA cycle diagrams, PDCA Process diagrams, and to construct the Quality Management Process Models, which all assist to manage efficiently the business processes, to improve quality of work and to reduce significantly the costs.

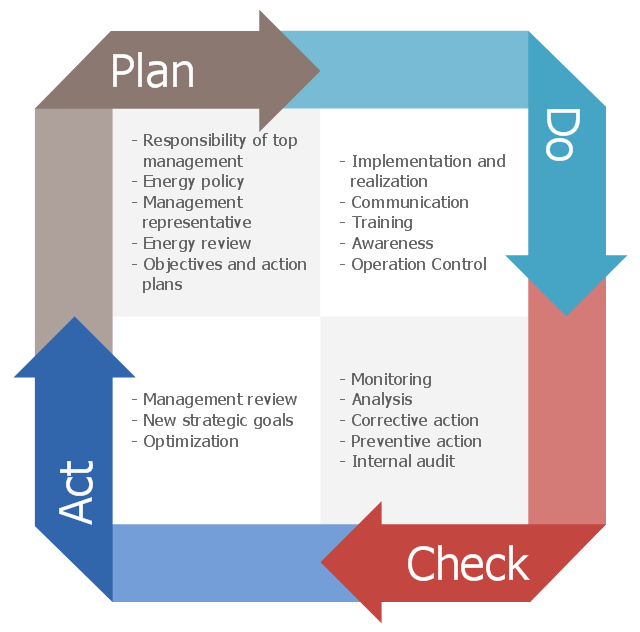

This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: PDCA ZIRKEL ENGL.png.

"The picture describes the 4 phases of the PDCA circle based on the specification ISO 50001." [commons.wikimedia.org/ wiki/ File:PDCA_ ZIRKEL_ ENGL.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The plan-do-check-act diagram example "PDCA cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: PDCA ZIRKEL ENGL.png.

"The picture describes the 4 phases of the PDCA circle based on the specification ISO 50001." [commons.wikimedia.org/ wiki/ File:PDCA_ ZIRKEL_ ENGL.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The plan-do-check-act diagram example "PDCA cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

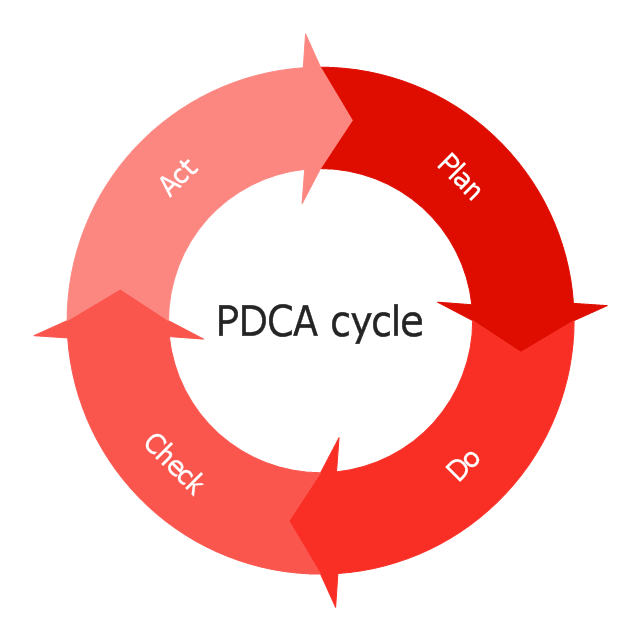

This circular arrows diagram sample depicts the Plan–Do–Check–Act cycle.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition." This emphasis on observation and current condition has currency with Lean manufacturing/ Toyota Production System literature." [PDCA. Wikipedia]

The diagram example "PDCA cycle" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Circular Arrows Diagrams solution from the area "What is a Diagram" of ConceptDraw Solution Park.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition." This emphasis on observation and current condition has currency with Lean manufacturing/ Toyota Production System literature." [PDCA. Wikipedia]

The diagram example "PDCA cycle" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Circular Arrows Diagrams solution from the area "What is a Diagram" of ConceptDraw Solution Park.

This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: Pdca.png. [commons.wikimedia.org/ wiki/ File:Pdca.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA (and other forms of scientific problem solving) is also known as a system for developing critical thinking. At Toyota this is also known as "Building people before building cars." Toyota and other Lean companies propose that an engaged, problem-solving workforce using PDCA is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations. This also creates a culture of problem solvers using PDCA and creating a culture of critical thinkers." [PDCA. Wikipedia]

The plan-do-check-act diagram example "PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: Pdca.png. [commons.wikimedia.org/ wiki/ File:Pdca.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"PDCA (and other forms of scientific problem solving) is also known as a system for developing critical thinking. At Toyota this is also known as "Building people before building cars." Toyota and other Lean companies propose that an engaged, problem-solving workforce using PDCA is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations. This also creates a culture of problem solvers using PDCA and creating a culture of critical thinkers." [PDCA. Wikipedia]

The plan-do-check-act diagram example "PDCA" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

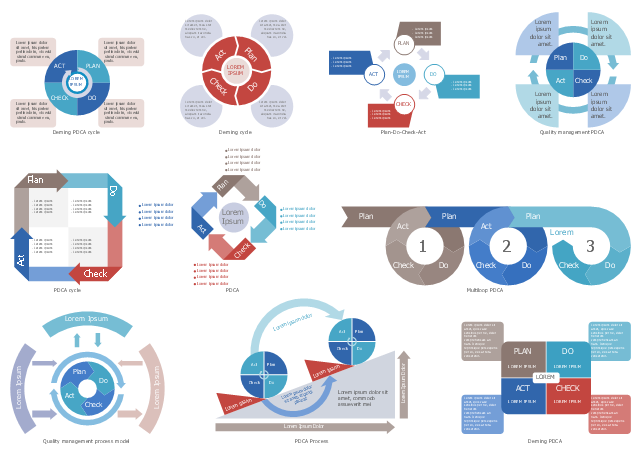

The vector stencils library PDCA contains 10 Plan-Do-Check-Act cycle diagram shapes.

Use it to design your Deming cycle diagrams with ConceptDraw PRO software.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition."" [PDCA. Wikipedia]

The Deming cycle diagrams sample "Design elements - PDCA" is included in Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

Use it to design your Deming cycle diagrams with ConceptDraw PRO software.

"PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/ cycle/ wheel, Shewhart cycle, control circle/ cycle, or plan–do–study–act (PDSA). Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say "Grasp the current condition."" [PDCA. Wikipedia]

The Deming cycle diagrams sample "Design elements - PDCA" is included in Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

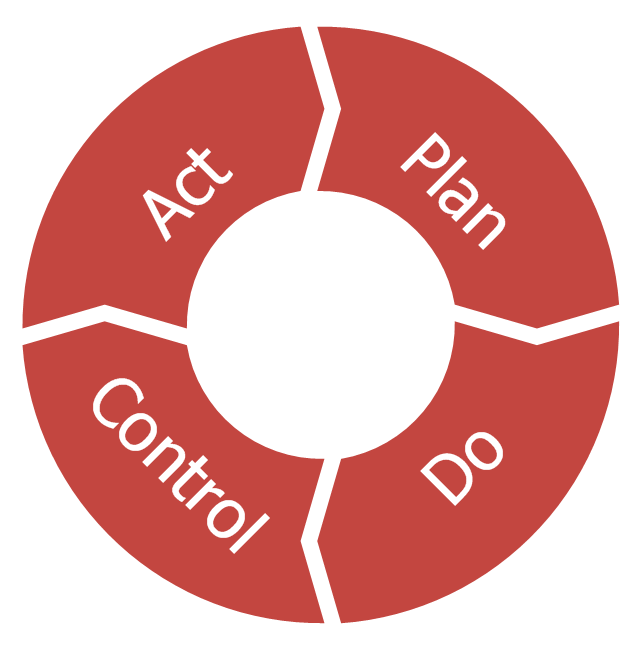

This Deming cycle sample shows plan-do-control-act diagram variance.

It was designed on the base of Wikimedia Commons file: Demingcycle.svg. [commons.wikimedia.org/ wiki/ File:Demingcycle.svg]

"PDCA was made popular by Dr W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he always referred to it as the "Shewhart cycle". Later in Deming's career, he modified PDCA to "Plan, Do, Study, Act" (PDSA) because he felt that "check" emphasized inspection over analysis. PDSA cycle was used to create the model of know-how transfer process." [PDCA. Wikipedia]

The plan-do-control-act diagram example "Deming cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: Demingcycle.svg. [commons.wikimedia.org/ wiki/ File:Demingcycle.svg]

"PDCA was made popular by Dr W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he always referred to it as the "Shewhart cycle". Later in Deming's career, he modified PDCA to "Plan, Do, Study, Act" (PDSA) because he felt that "check" emphasized inspection over analysis. PDSA cycle was used to create the model of know-how transfer process." [PDCA. Wikipedia]

The plan-do-control-act diagram example "Deming cycle" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

HelpDesk

How to Create PDCA Diagram

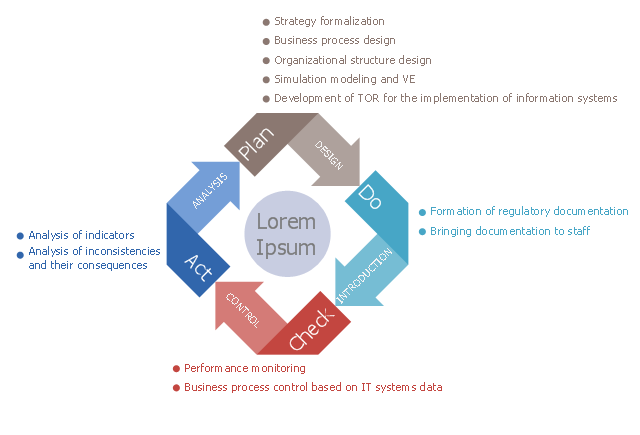

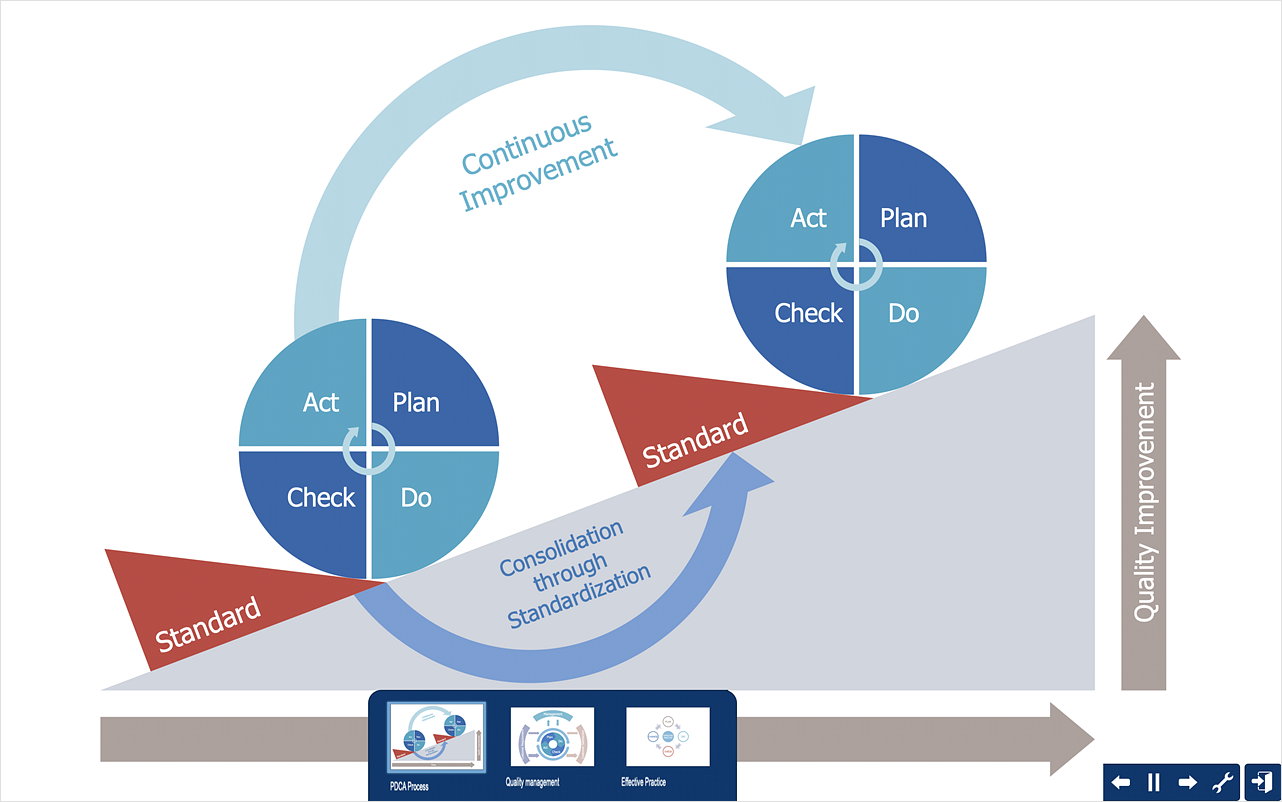

Plan-Do-Check-Act (PDCA) solution for ConceptDraw DIAGRAM helps to design the Plan Do Study Act diagrams, PDCA cycle diagrams, PDCA Process diagrams, and to construct the Quality Management Process Models. It is used for easy visualization of PDCA cycle, PDSA cycle, or Deming cycle - the management methods of the business process continuous improvement.This Deming cycle sample shows plan-do-check-act diagram.

It was designed on the base of Wikimedia Commons file: Prozessmodell (Qualitätsmanagement).svg.

"German illustration of the quality management process model (closed loop system), including the PDCA circle" [commons.wikimedia.org/ wiki/ File:Prozessmodell_ (Qualitätsmanagement).svg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The plan-do-check-act diagram example "Quality management process model" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

It was designed on the base of Wikimedia Commons file: Prozessmodell (Qualitätsmanagement).svg.

"German illustration of the quality management process model (closed loop system), including the PDCA circle" [commons.wikimedia.org/ wiki/ File:Prozessmodell_ (Qualitätsmanagement).svg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The plan-do-check-act diagram example "Quality management process model" was designed using ConceptDraw PRO software extended with Plan-Do-Check-Act (PDCA) solution from Management area of ConceptDraw Solution Park.

- Deming Cycle Wiki

- Plan-Do-Check-Act (PDCA) | Deming cycle | Deming PDCA cycle ...

- Plan-Do-Check-Act (PDCA) | Deming PDCA cycle | Circular arrows ...

- How to Create PDCA Diagram | Plan-Do-Check-Act (PDCA ...

- Plan-Do-Check-Act (PDCA) | How to Create PDCA Diagram ...

- Cycle Png

- How to Create PDCA Diagram | Plan-Do-Check-Act (PDCA) | PDCA ...

- Plan-Do-Check-Act (PDCA) | How to Create PDCA Diagram ...

- Deming PDCA | Design elements - Control chart | Circular arrows ...

- How to Create PDCA Diagram | Circular arrows diagram - PDCA ...