Mechanical Engineering

Mechanical Engineering

This solution extends ConceptDraw PRO v.9 mechanical drawing software (or later) with samples of mechanical drawing symbols, templates and libraries of design elements, for help when drafting mechanical engineering drawings, or parts, assembly, pneumatic,

Chemical and Process Engineering

Chemical and Process Engineering

This chemical engineering solution extends ConceptDraw PRO v.9.5 (or later) with process flow diagram symbols, samples, process diagrams templates and libraries of design elements for creating process and instrumentation diagrams, block flow diagrams (BFD

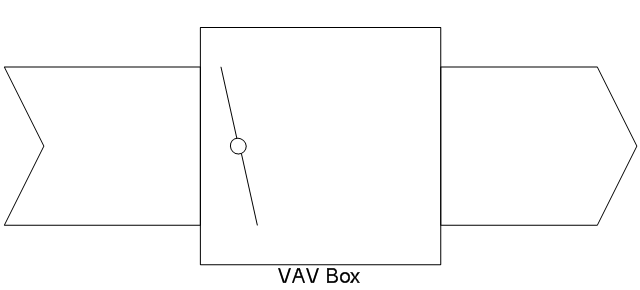

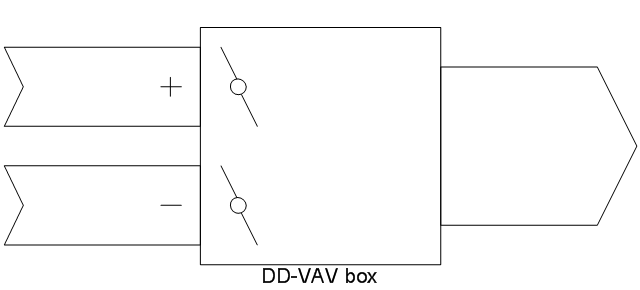

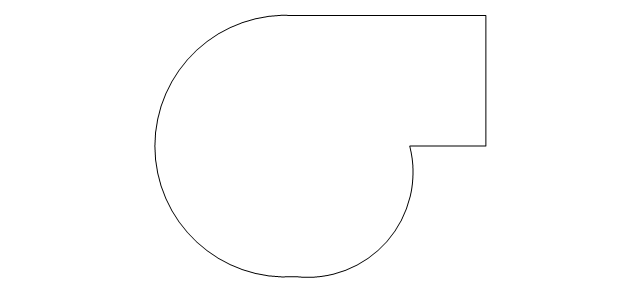

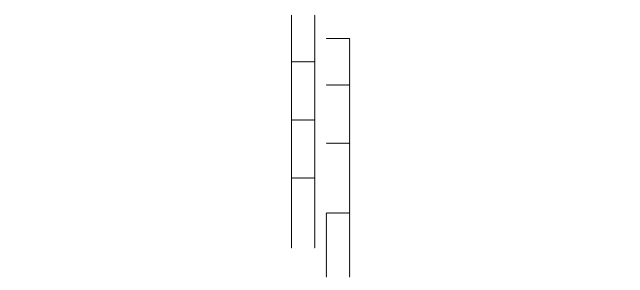

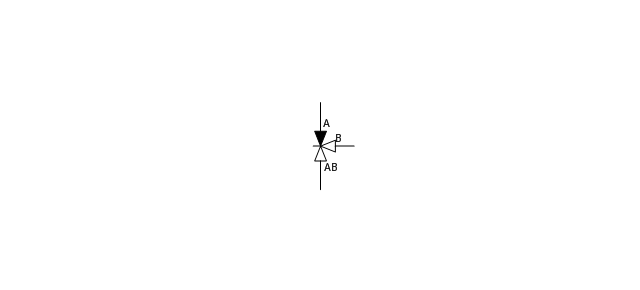

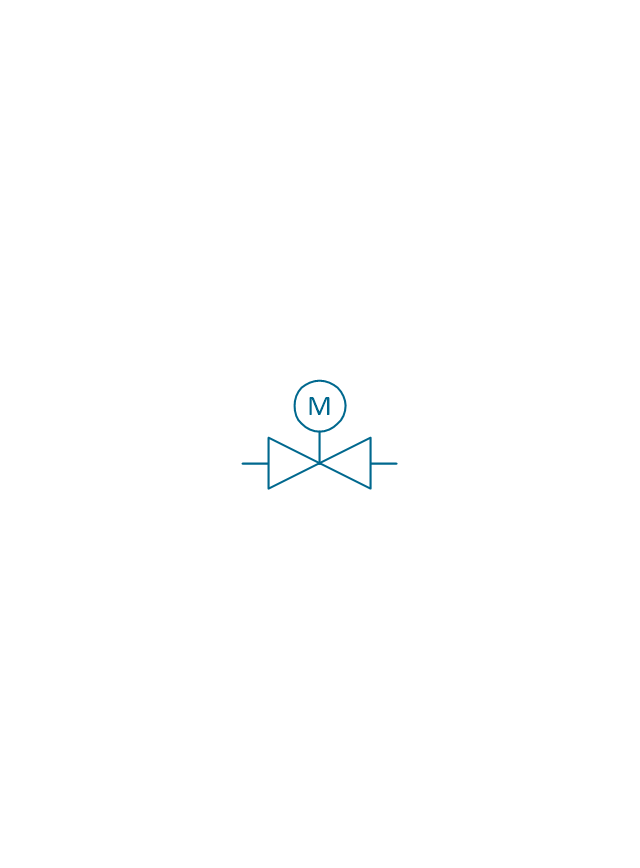

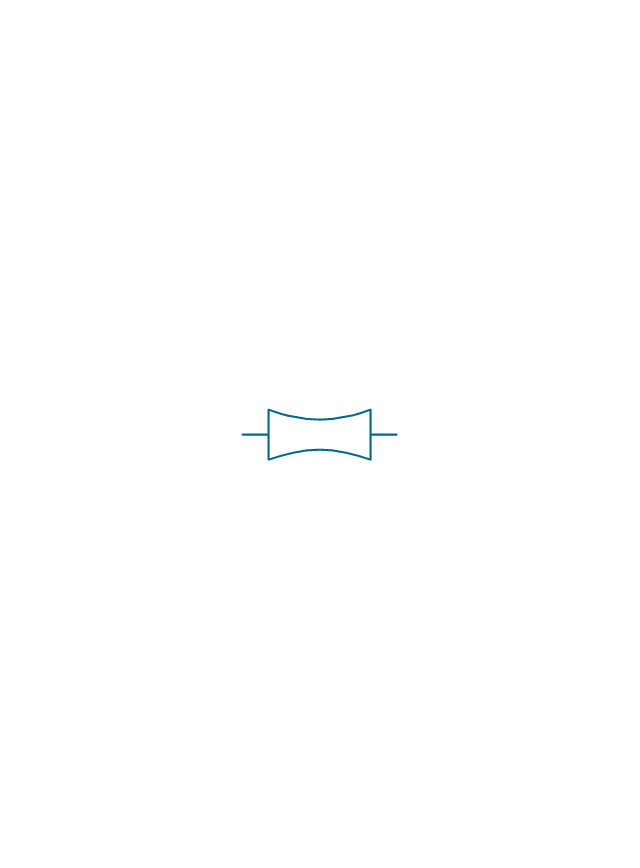

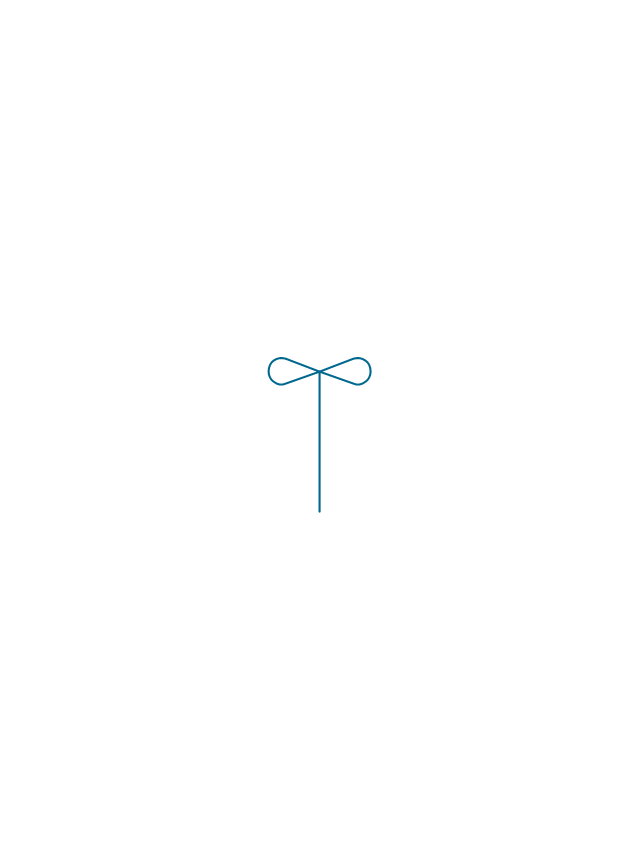

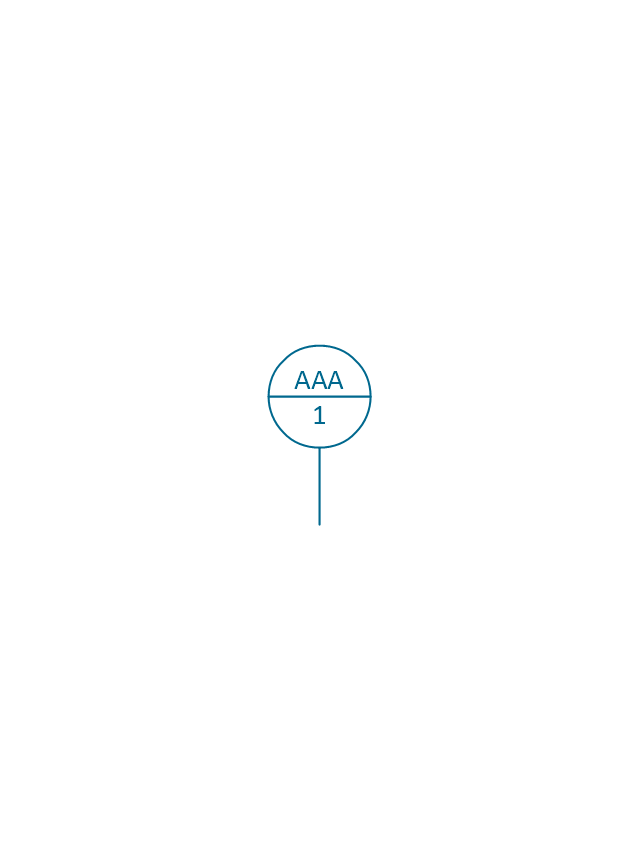

The vector stencils library "HVAC control equipment" contains 48 HVAC symbols. Use it for drawing HVAC systems diagrams, heating, ventilation, air conditioning, refrigeration, automated building control, and environmental control design building plans and equipment layouts. The symbols example "HVAC control equipment - Vector stencils library" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the HVAC Plans solution from the Building Plans area of ConceptDraw Solution Park.

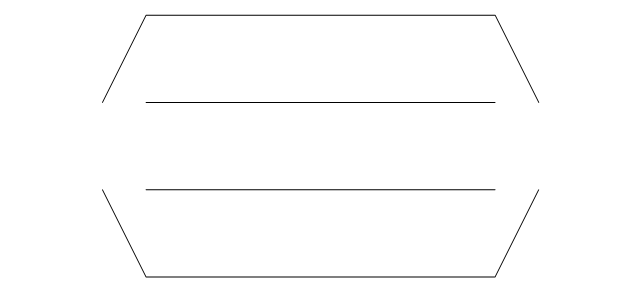

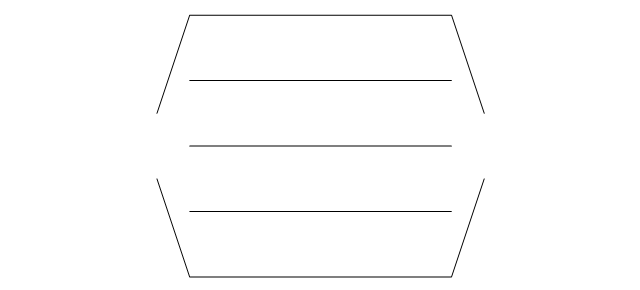

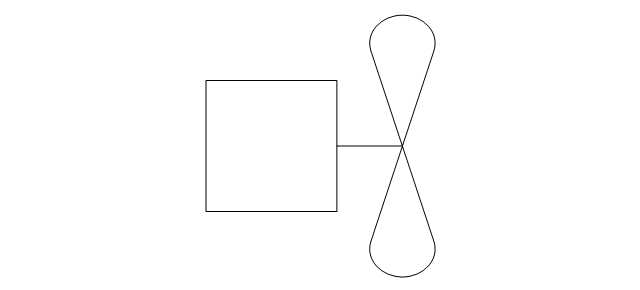

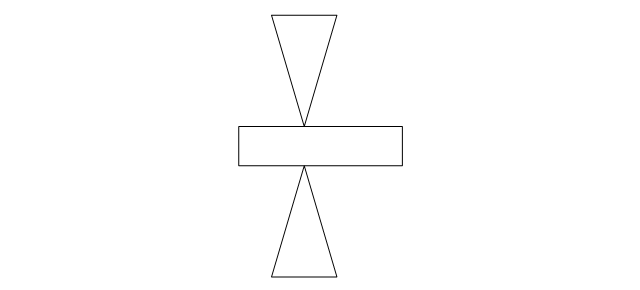

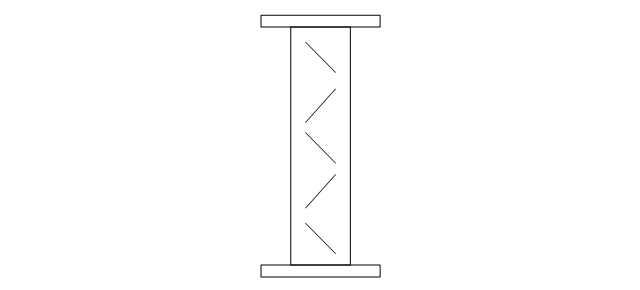

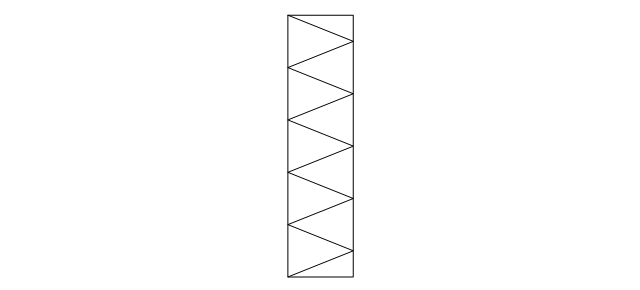

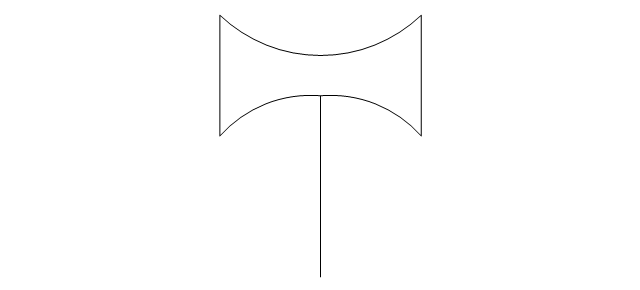

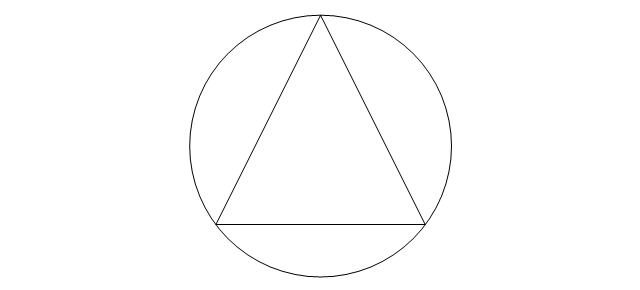

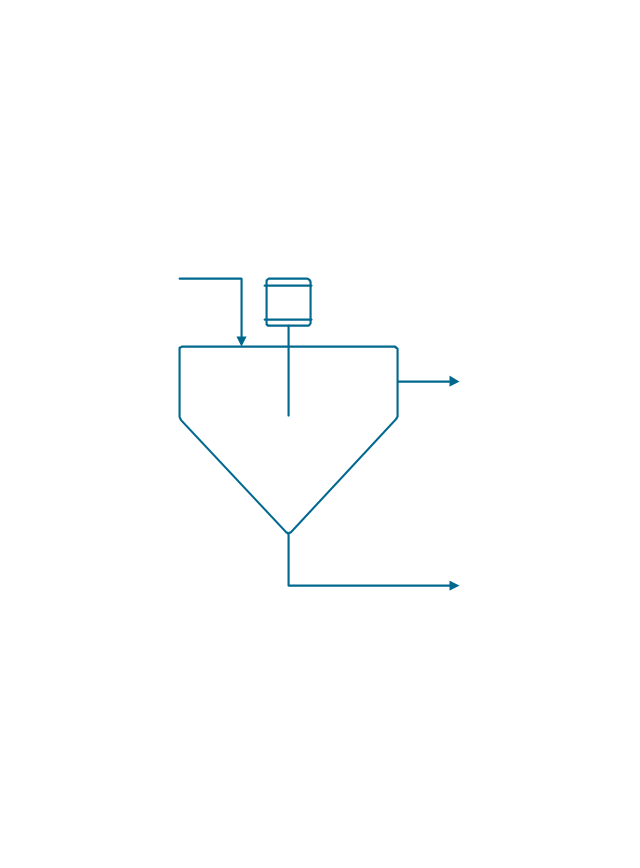

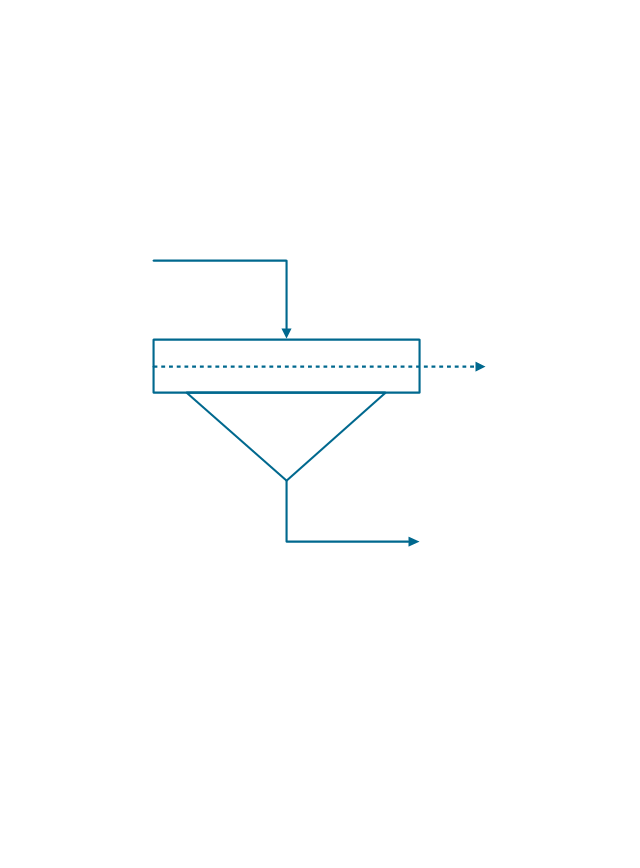

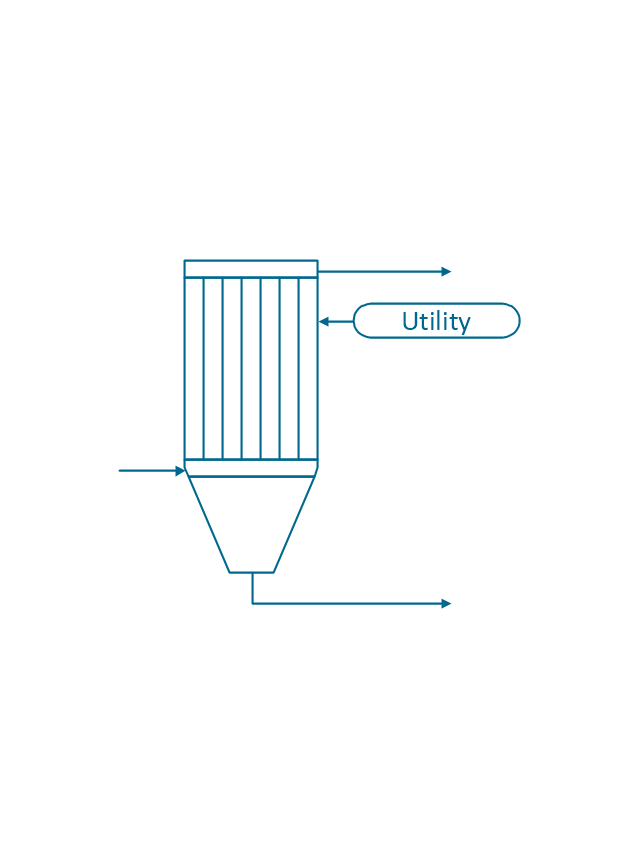

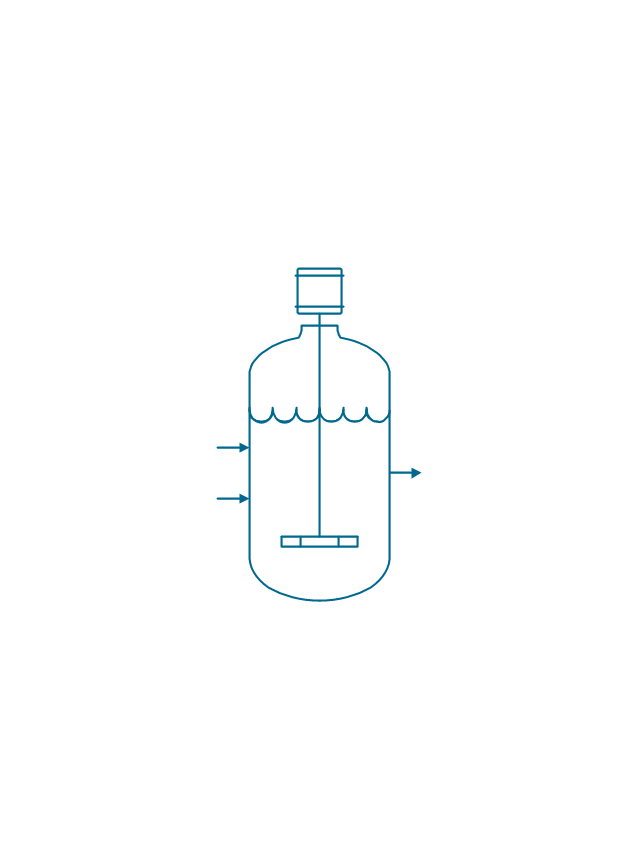

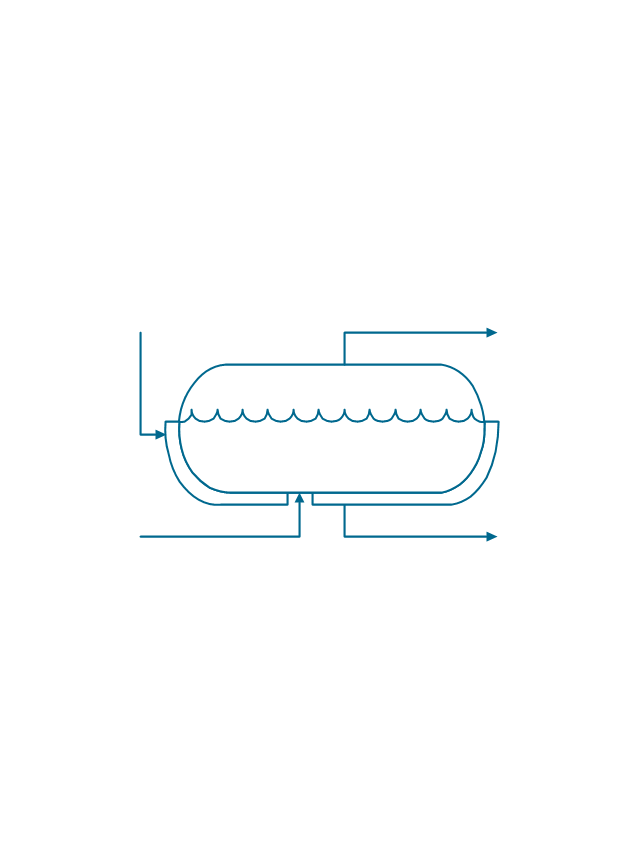

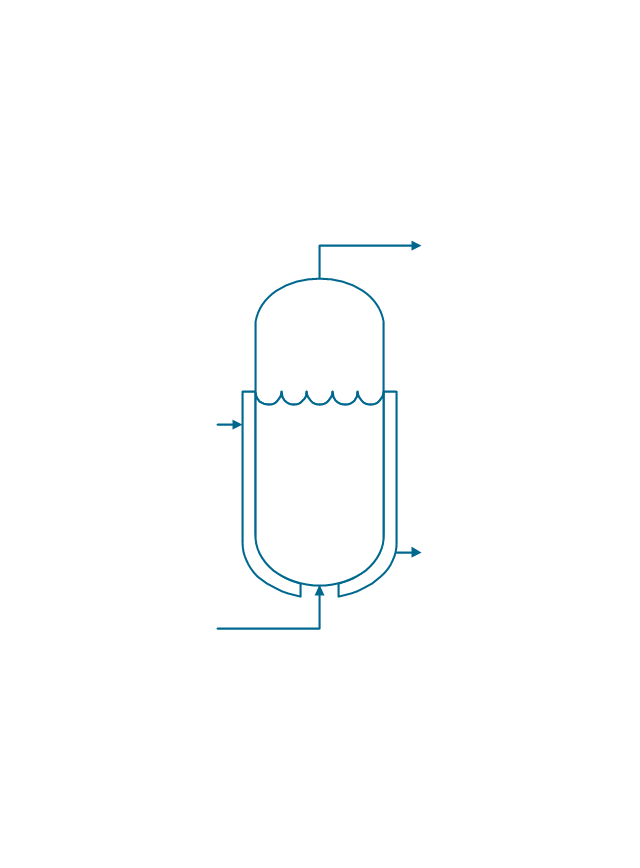

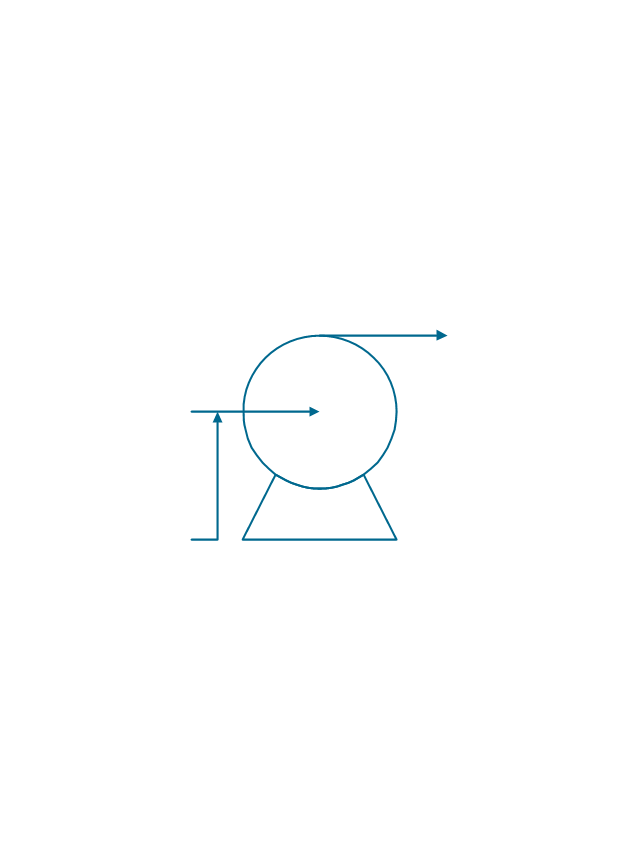

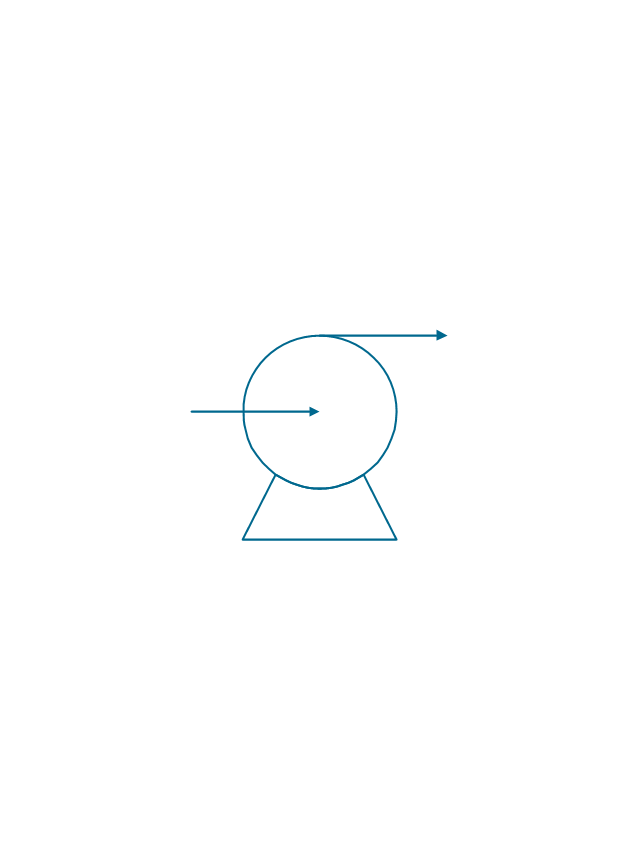

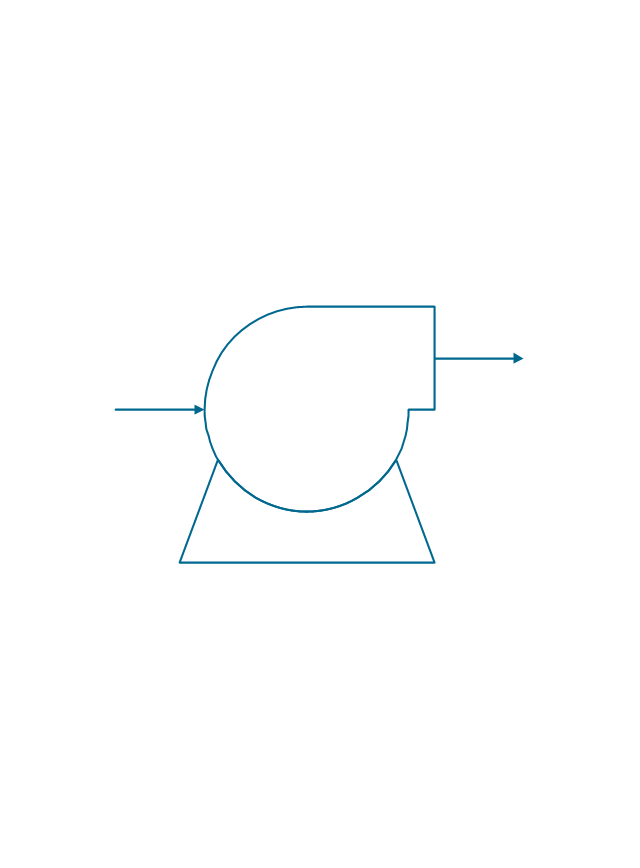

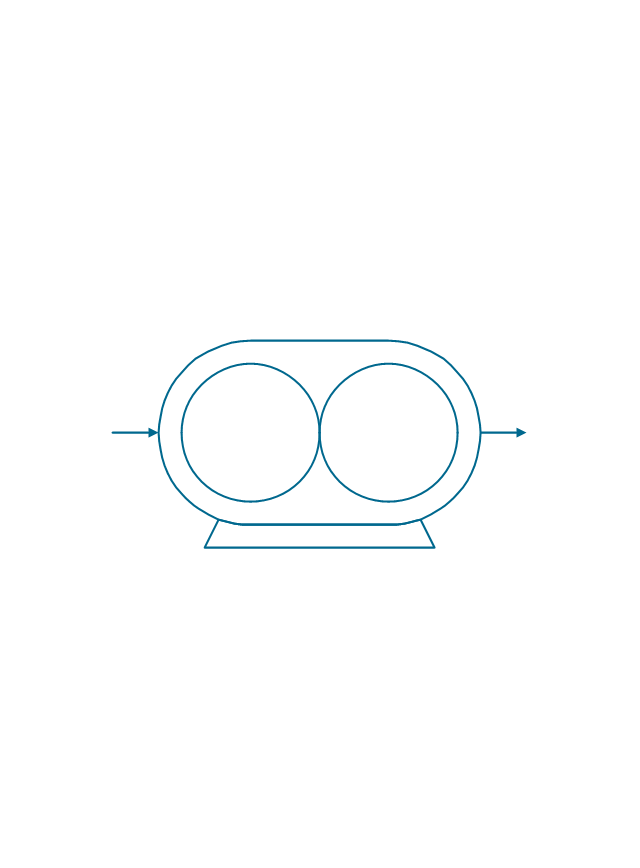

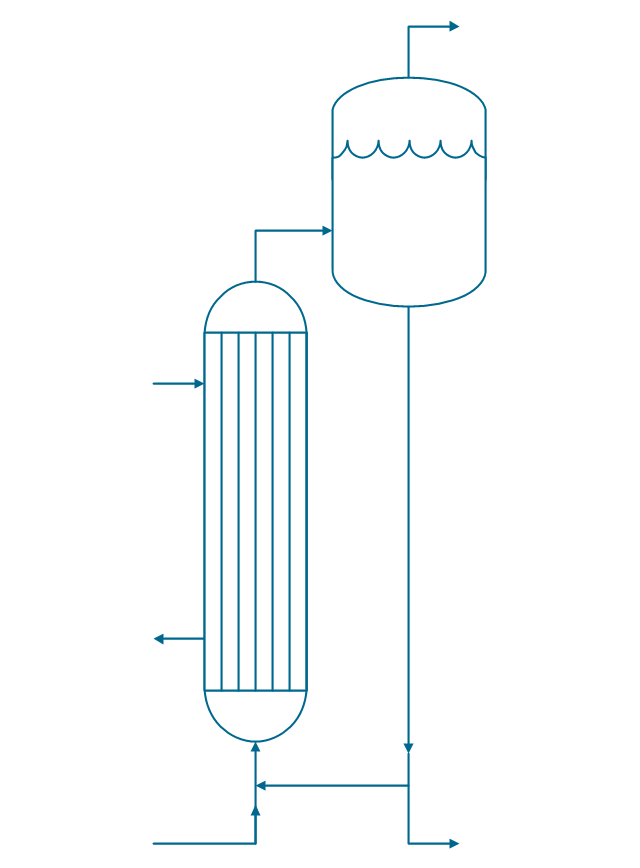

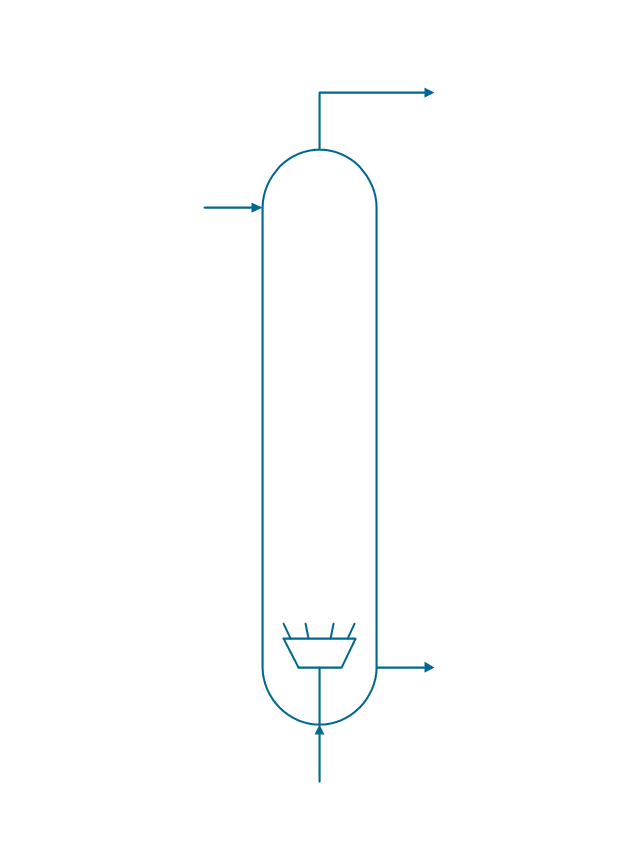

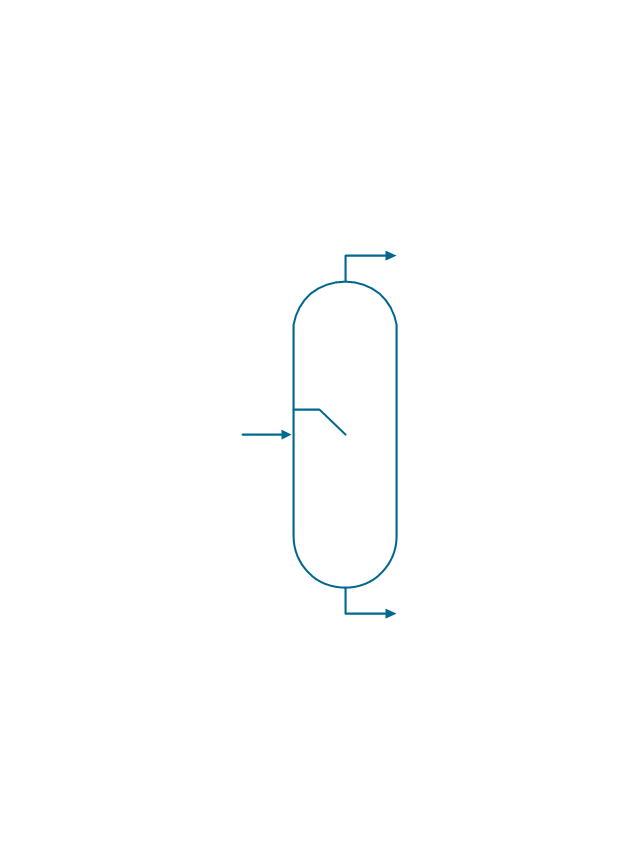

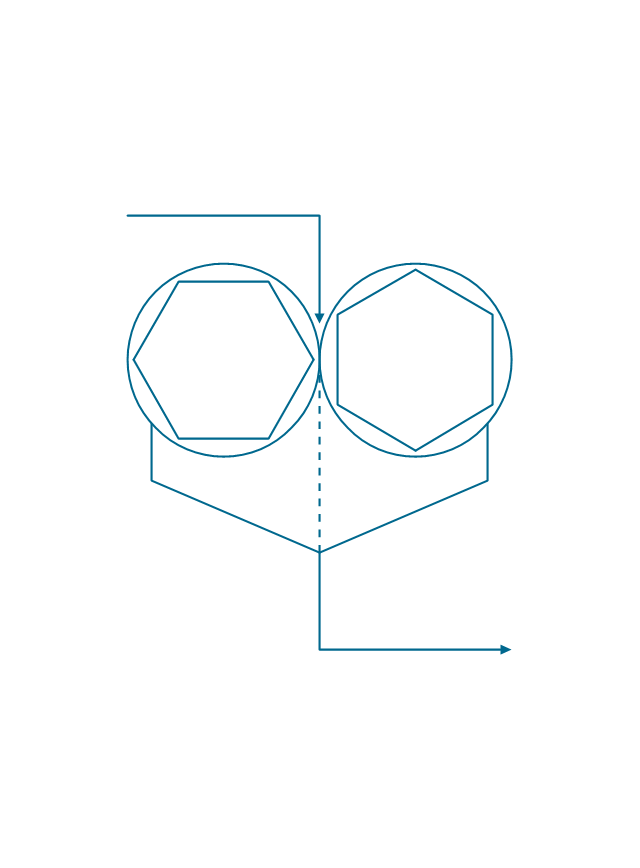

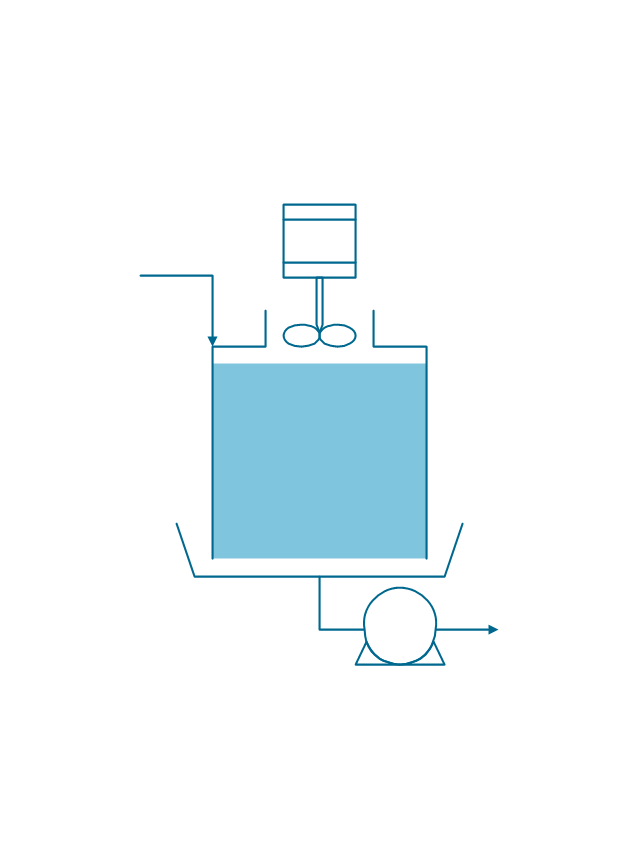

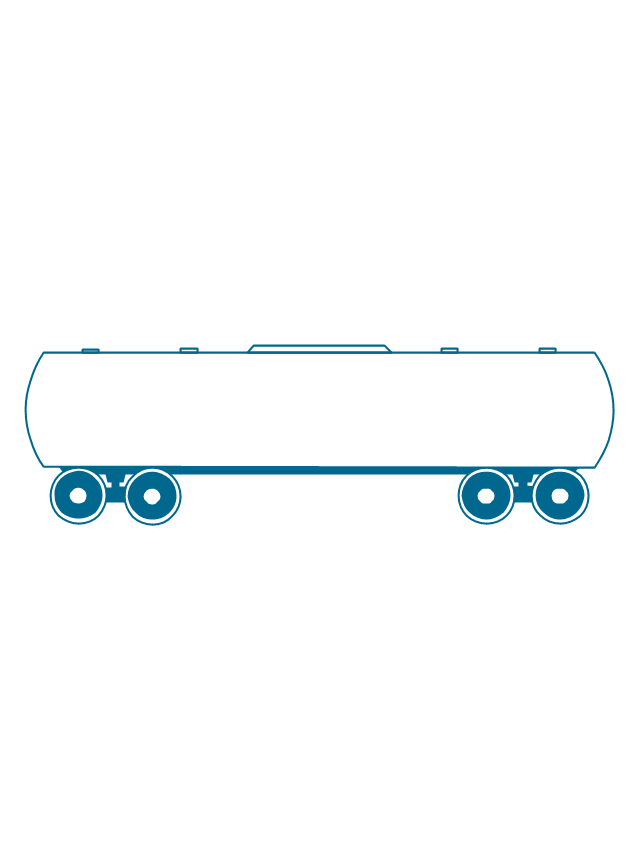

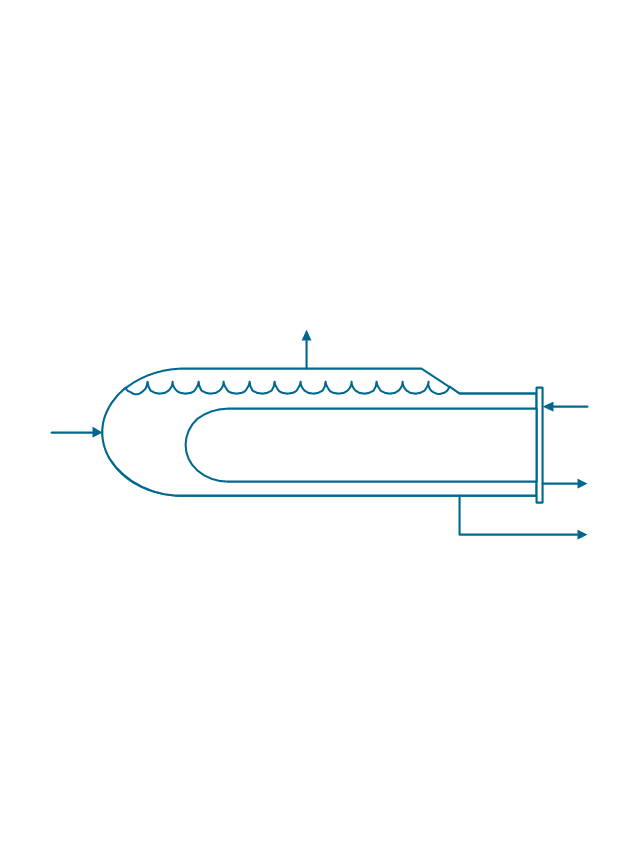

The vector stencils library "Chemical engineering" contains 24 symbols of chemical and process engineering equipment.

Use these shapes for drawing Process Flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), and Water Flow Diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-chemical-process

Use these shapes for drawing Process Flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), and Water Flow Diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-chemical-process

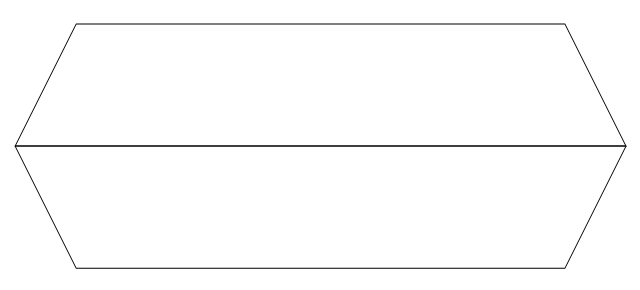

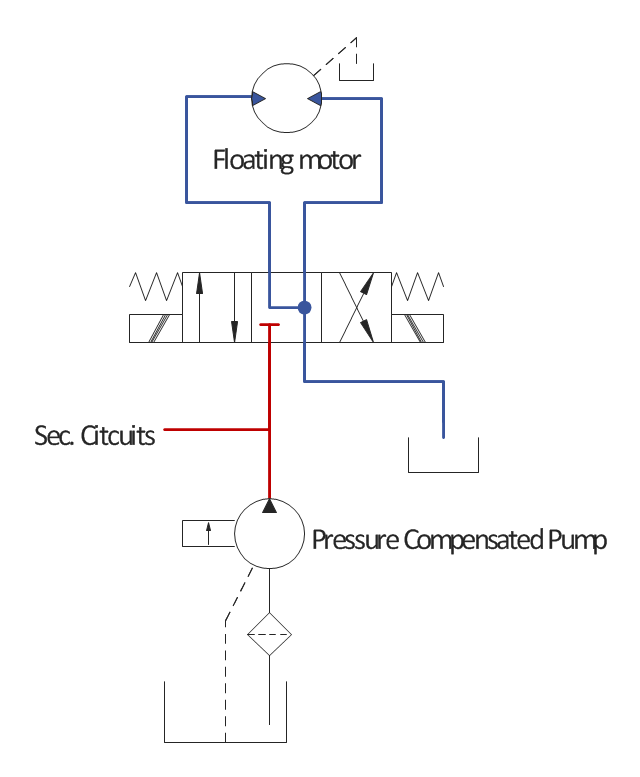

This example engineering drawing showing the hydraulic directional control valve usage with floating motor and pressure compensated pump is redesigned using the ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: DCV 17.jpg.

[commons.wikimedia.org/ wiki/ File:DCV_ 17.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

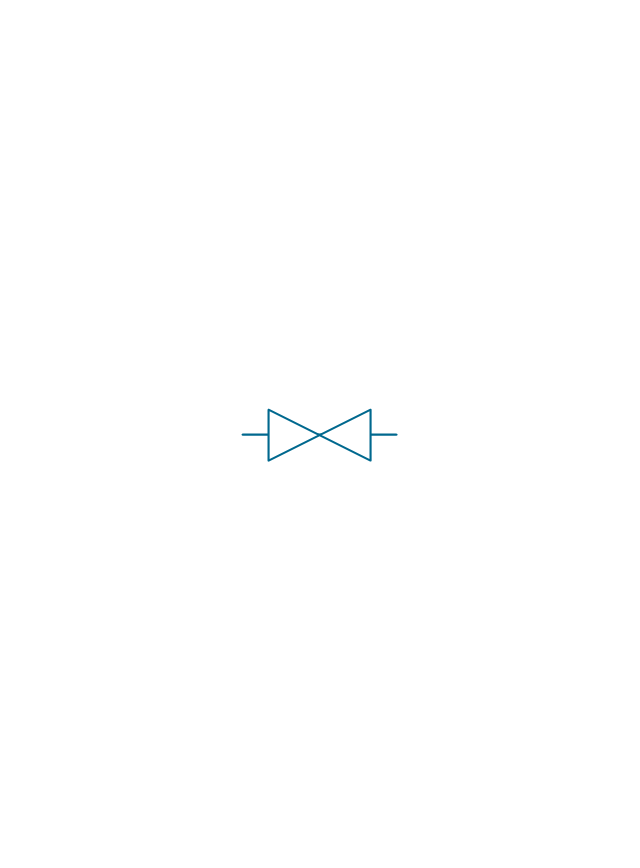

"Directional control valves are one of the most fundamental parts in hydraulic machinery as well and pneumatic machinery. They allow fluid flow into different paths from one or more sources. They usually consist of a spool inside a cylinder which is mechanically or electrically controlled. The movement of the spool restricts or permits the flow, thus it controls the fluid flow. ...

The spool (sliding type) consists of lands and grooves.The lands block oil flow through the valve body. The grooves allow oil or gas to flow around the spool and through the valve body. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. There is another class of valves with 3 or more position that can be spring centered with 2 working position and a normal position. ...

Directional control valves can be classified according to:

(1) number of ports;

(2) number of positions;

(3) actuating methods;

(4) type of spool." [Directional control valve. Wikipedia]

The fluid power equipment drawing example "Directional control valve" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

[commons.wikimedia.org/ wiki/ File:DCV_ 17.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"Directional control valves are one of the most fundamental parts in hydraulic machinery as well and pneumatic machinery. They allow fluid flow into different paths from one or more sources. They usually consist of a spool inside a cylinder which is mechanically or electrically controlled. The movement of the spool restricts or permits the flow, thus it controls the fluid flow. ...

The spool (sliding type) consists of lands and grooves.The lands block oil flow through the valve body. The grooves allow oil or gas to flow around the spool and through the valve body. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. There is another class of valves with 3 or more position that can be spring centered with 2 working position and a normal position. ...

Directional control valves can be classified according to:

(1) number of ports;

(2) number of positions;

(3) actuating methods;

(4) type of spool." [Directional control valve. Wikipedia]

The fluid power equipment drawing example "Directional control valve" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

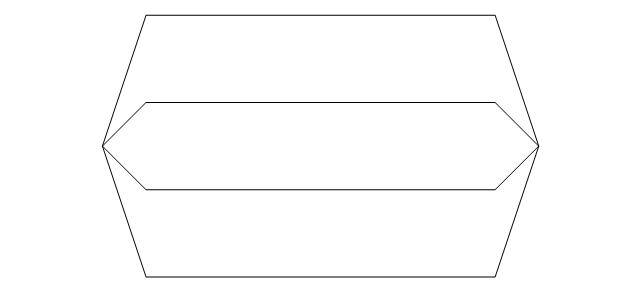

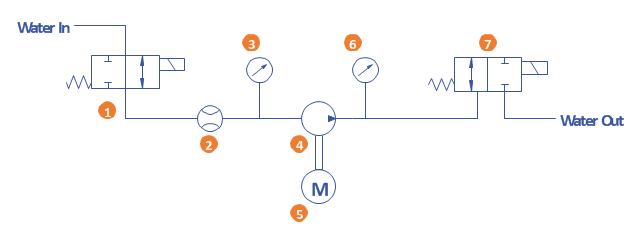

A simple hydraulic schematic showing apparatus for testing the strength of a hydraulic hose splice.

Water enters through normally closed solenoid valve (1) and passes through intake flow meter (2) to high pressure pump (4). Intake water pressure is monitored by pressure gauge (3). The hose to be tested connects between pump (4) and normally open solenoid activated drain valve (7). To test the hose, pump drive motor (5) is turned on, the solenoid of drain valve (7) is activated, closing the valve, and the pump is run to pressurize the hose. Test pressure is monitored by gauge (6). When the test is complete or the hose fails, the solenoid of drain valve (7) is deactivated, opening valve and discharging water, depressurizing the system. All components are operated electrically by a remote control circuit so that the operator may perform the test from a protected location, monitoring it with a camera and video monitor.

This hydraulic schematic example was redrawn using ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: Hydraulic schematic.jpg.

[commons.wikimedia.org/ wiki/ File:Hydraulic_ schematic.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The hydraulic schematic example "Apparatus for testing the strength of a hydraulic hose splice" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

Water enters through normally closed solenoid valve (1) and passes through intake flow meter (2) to high pressure pump (4). Intake water pressure is monitored by pressure gauge (3). The hose to be tested connects between pump (4) and normally open solenoid activated drain valve (7). To test the hose, pump drive motor (5) is turned on, the solenoid of drain valve (7) is activated, closing the valve, and the pump is run to pressurize the hose. Test pressure is monitored by gauge (6). When the test is complete or the hose fails, the solenoid of drain valve (7) is deactivated, opening valve and discharging water, depressurizing the system. All components are operated electrically by a remote control circuit so that the operator may perform the test from a protected location, monitoring it with a camera and video monitor.

This hydraulic schematic example was redrawn using ConceptDraw PRO diagramming and vector drawing software from the Wikimedia Commons file: Hydraulic schematic.jpg.

[commons.wikimedia.org/ wiki/ File:Hydraulic_ schematic.jpg]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license.

[creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

The hydraulic schematic example "Apparatus for testing the strength of a hydraulic hose splice" is included in the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park.

- Valve Pump Symbol

- Mechanical Drawing Symbols | Hydraulic pumps and motors ...

- Directional control valve | Pressure Compensated Pump Symbol

- Symbol Of Motor Pump Valve In Line Diagram

- A Valve Pump Engineering Drawing

- Mechanical Drawing Symbols | Design elements - Valve assembly ...

- Process Flow Diagram | Symbol Of Pump With Name

- Mechanical Drawing Symbols | Mechanical Engineering ...

- Pump Symbol

- Mechanical Drawing Symbols | Mechanical Engineering ...

- Pump Valve Symbol Schematic

- Symbols Of Pumps And Valves In Chemical Engineering

- Directional control valve | Double Acting Solenoid Valve Symbol

- Pump Diagram Symbols

- Mechanical Drawing Symbols | Mechanical Engineering ...

- Distilling Plant Diagram Showing Valves And Pump

- Mechanical Drawing Symbols | Pneumatic 5-ported 3-position valve ...

- Pneumatic Valve Symbols And Pumps

- Mechanical Drawing Symbols | Design elements - Hydraulic pumps ...

- Technical Symbol For Machanical Valve And Pumps