Lean Value Stream Mapping

Value Stream Mapping solution is a Lean Manufacturing tool that use a flow diagram to document in great detail every step of a manufacturing process. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes in any organization.

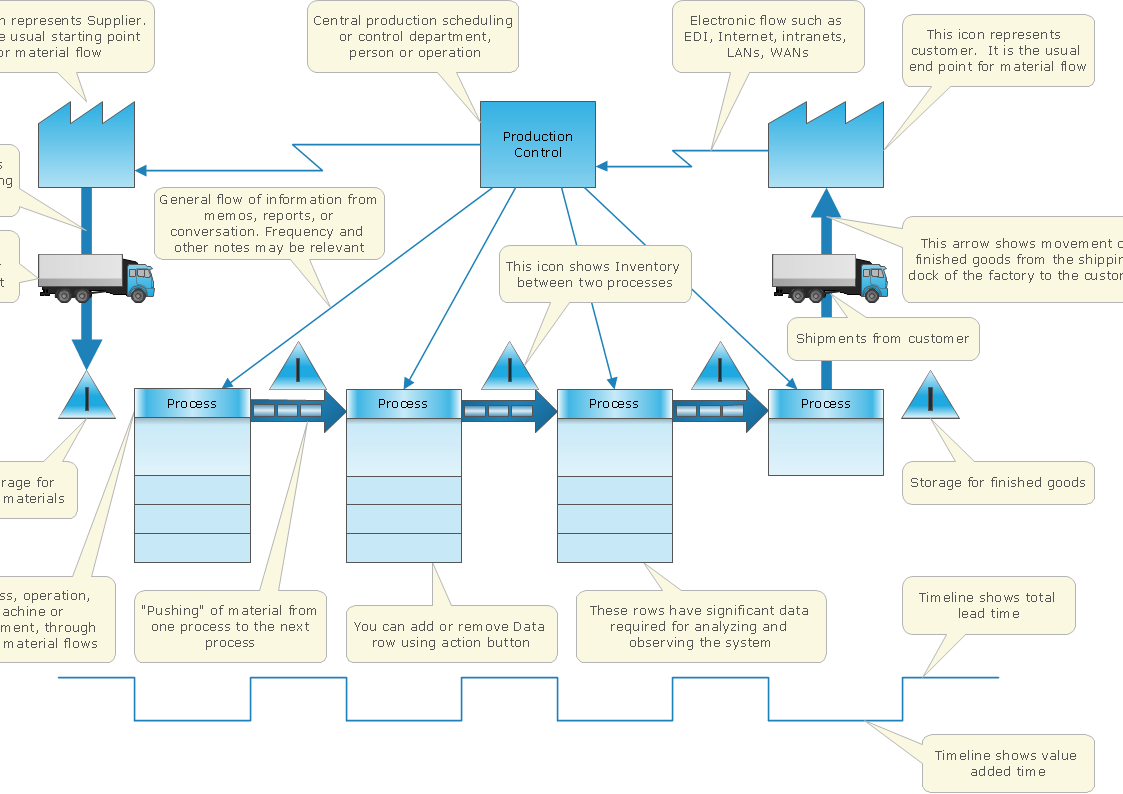

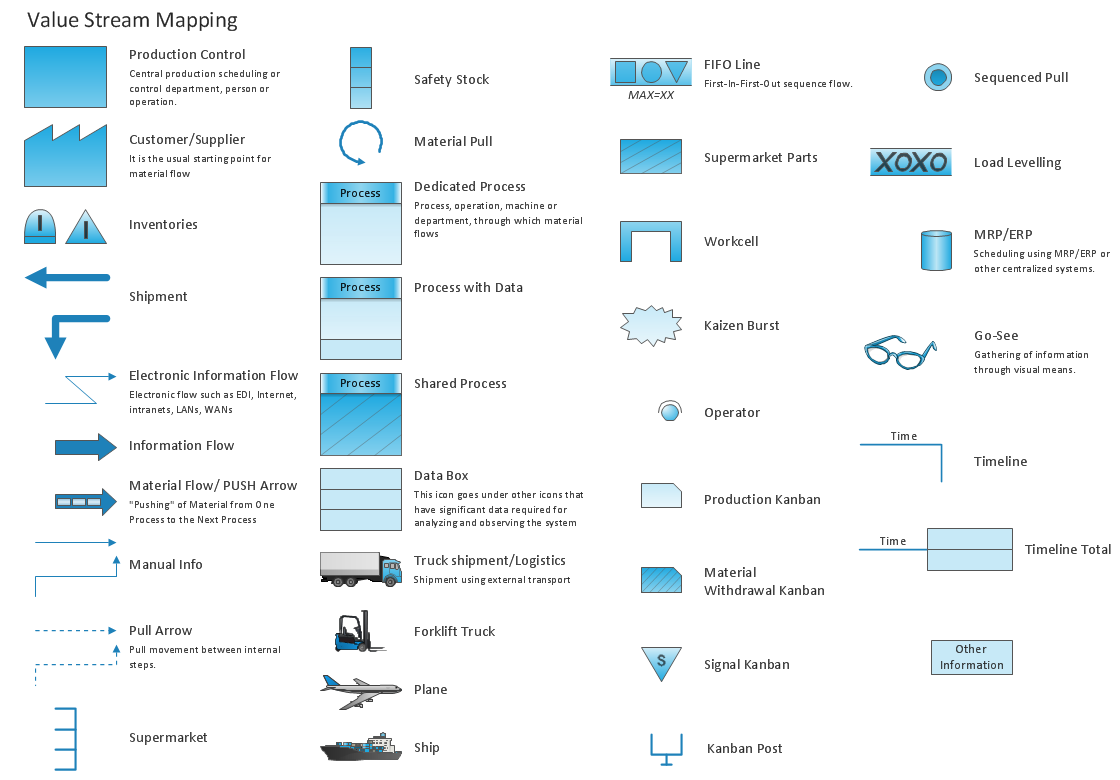

Pic.1 Template of Value Stream Map (VSM).

Value Stream Maps are used in lean manufacturing methodology to analyze and identify the process improvement opportunities that are available.

See also Samples:

THREE RELATED HOW TO's:

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product or service to customers

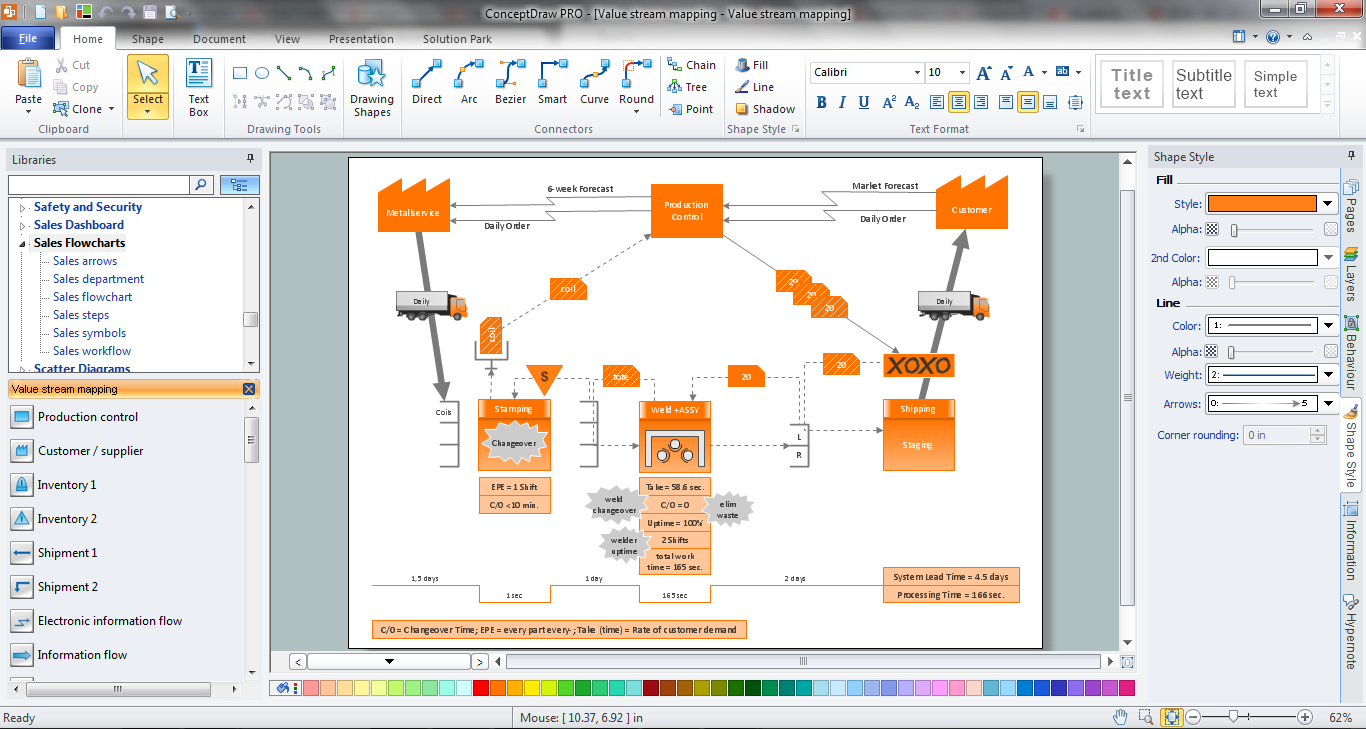

Picture: Value Stream Mapping

Related Solution:

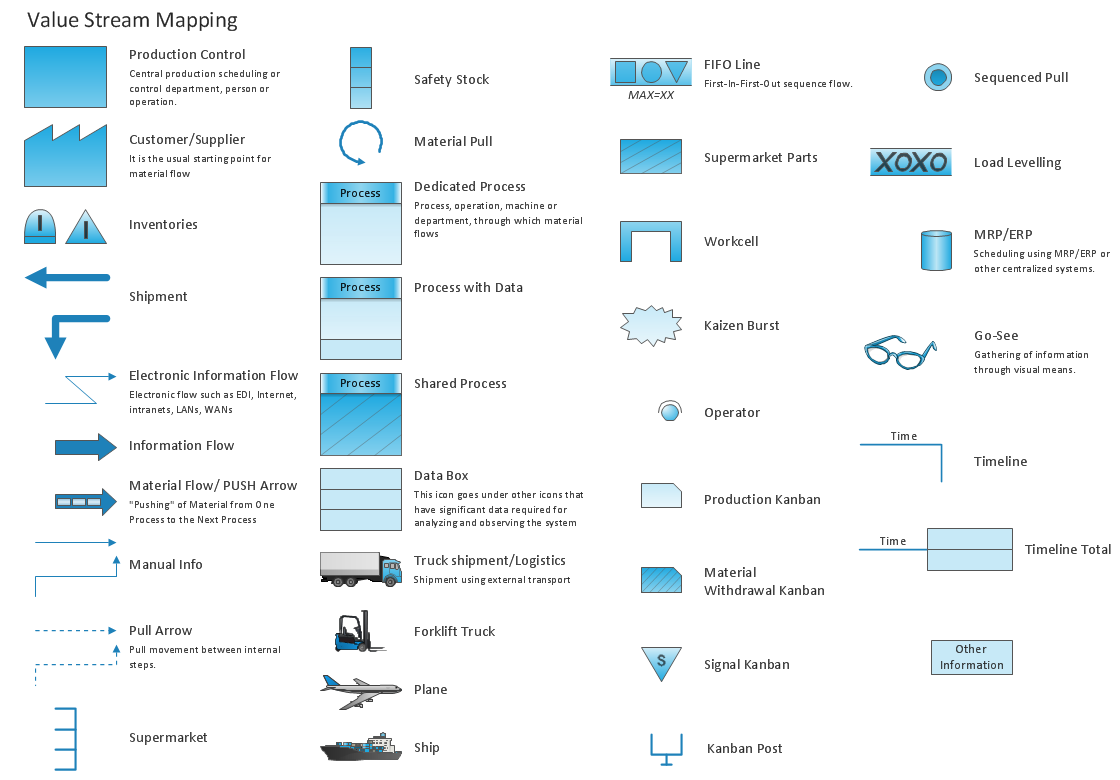

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.

Picture: Value Stream Mapping Symbols

Related Solution:

ConceptDraw Value Stream Maps are used in lean practice for analysis of manufacturing processes to identify the improvement opportunities.

Picture: Value Stream Analysis

Related Solution:

ConceptDraw

MINDMAP 16