Electric Generators

A generator is a device that converts mechanical energy obtained from an external source (fuel-based power) or kinetic energy into electric power or electricity as the output. To get kinetic energy, multiple fuels like natural gas, diesel, petrol, gasoline, propane, and LPG are used. Diesel generators are the most popular generators on the market, small portable generators commonly operate on gasoline. There are also bi-fuel generators capable to run on both diesel and gasoline.

The generated electric power is then stored in batteries or directly supplied and distributed in an external circuit over power lines to commercial, industrial and domestic customers, or is transmitted and used in transport like automobiles, trains, aircraft, ships, etc. Sources of mechanical energy include internal combustion engines, steam turbines, gas turbines, gasoline and diesel engines, and renewable energy sources like water turbines, hydraulic turbines at dams or waterfalls, wind turbines, and solar-powered turbines.

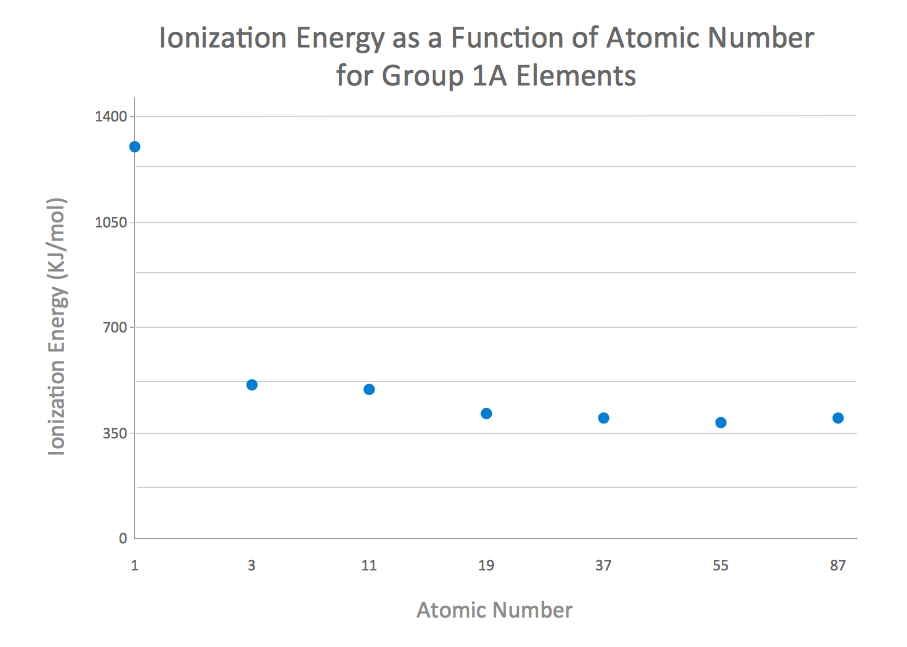

The first electric generators were creating direct current, currently, alternating current generators are widespread due to their higher efficiency and cheaper cost. The generated alternating current reverses polarity at a fixed frequency, in common 50-60 cycles.

Electric generators are incredibly useful to provide electricity when power from the local grid is unavailable. They are the way to supply backup power to various facilities or a primary power source in areas where there is no local electrical grid, or where its construction is impossible or it is difficult to access.

There are electric generators with a wide range of power output capacities for different purposes, portable and stationary. Portable devices are used for camping, hobbies, or other individual purposes, while permanent installations power entire houses or offices. Powerful generators of industrial size are installed in hospitals, large manufacturers, and other facilities. For example, the generators set on dams have enormous power and provide great amounts of energy by transferring power created by water-turning turbines. As for the noise characteristic, there are models with noise-reducing technology for use in close proximity to residential.

A generator uses mechanical energy to force the movement of electric charges present in the wire of its windings through an external electric circuit. This flow of electric charges is an electric current supplied by the generator. Several generators connected to a single power network should be synchronous and operate at the same frequency.

The operation of electric generators is based on the principle of electromagnetic induction. The generator includes a conductor copper coil tightly wound onto a metal core and is a kind of electromagnet. The coil is connected to a mechanical energy source and moves or rotates rapidly between the poles of a horseshoe-type magnet, and cuts the magnetic field between two poles of the magnet.

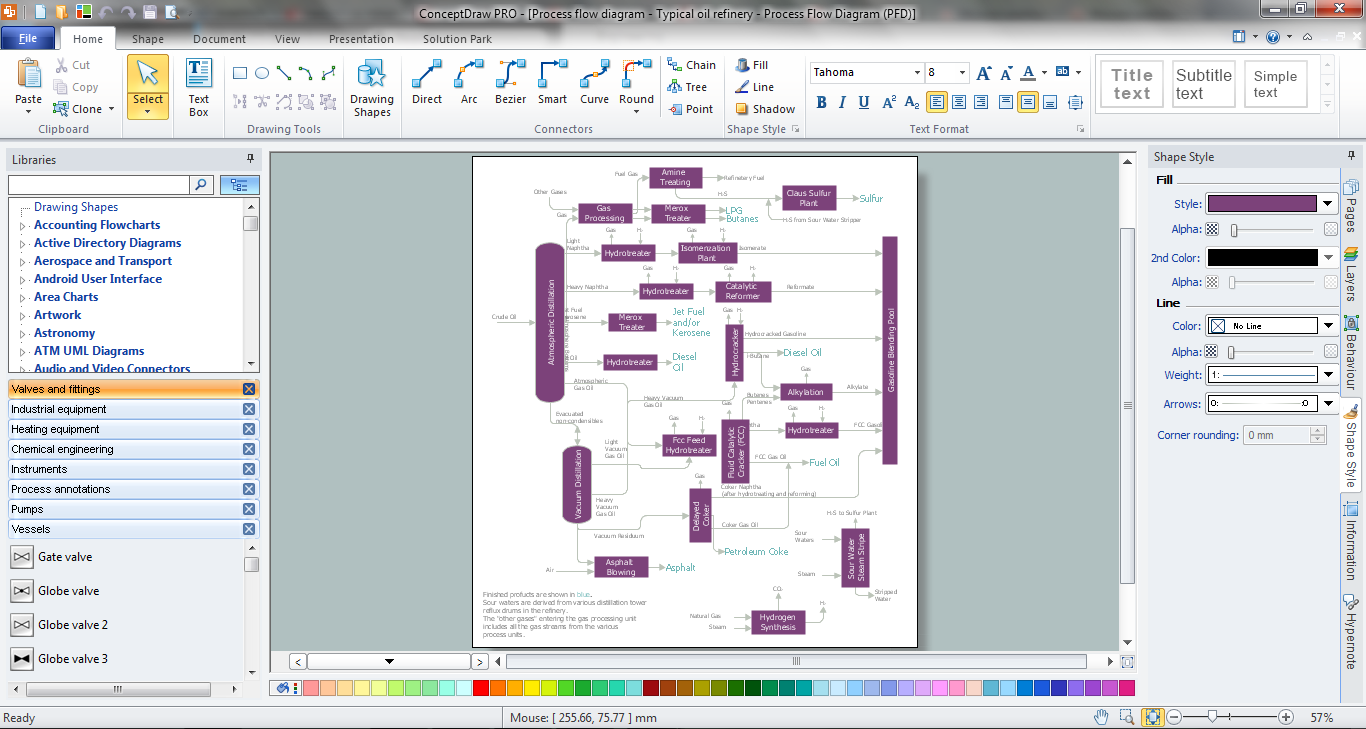

Example 1. Electric Generators Design in ConceptDraw DIAGRAM

Generators are electrical motors working in reverse and forcing electrons from the external source through an electrical circuit. The construction and the speed of the generators may vary. The main components of an electric generator are engine, alternator, fuel system, cooling and exhaust systems, voltage regulator, battery charger, lubrication system, and control panel, placed into a housing with the main assembly or frame.

The engine is the source of the input mechanical energy, which it supplies to the generator and its size is directly proportional to its maximum power output.

The alternator uses the mechanical energy supplied by the engine to produce the electrical output. It contains stationary parts (stator) and moving ones (rotor or armature), which cause relative movement, appearing of an electromagnetic field, and generation of electricity through interaction.

The fuel system provides the necessary raw materials to the generator and initiates the internal combustion process to produce energy. Because without fuel, there is no combustion and the generator can’t convert the mechanical energy into electricity. The fuel system includes fuel tank, fuel pump that forces fuel into the combustion chamber, fuel injector, fuel pipe, ventilation pipe, drain pipe, overflow connection, fuel water separator or fuel filter, which cleans fuel from debris before it gets to the engine and the injector. The fuel tank supports the generator's operation in common over 6-10 hours. The tank's capacity differs and depends on the application and type of generator. The bigger it is, the longer generator can operate. The tanks are mounted to the generator frame or are external, located above ground, below ground, or sub-base. The installation of big external fuel tanks is often implemented for commercial use.

The voltage regulator controls and regulates the output voltage of the generator. It rectifies and converts the output of AC voltage into DC current that is fed to the rotor or armature to create an electromagnetic field and convert DC current to AC voltage. This happens until the generator begins producing output voltage equivalent to its full operating capacity.

The cooling and exhaust systems with raw or fresh water, or hydrogen are essential to withdraw heat produced in a great amount during the electric power generation process. The cooling system protects the equipment from overheating. The exhaust system helps to remove fumes and exhaust gases emitted by using fuel.

The lubricating system operating with oil stored in a pump ensures durability and smooth operation of the generator for a long period of time. It is important that moving parts inside a generator be well lubricated, this saves them from excess wear and ensures smooth operation.

The battery charger is a fully automatic component that keeps charged the generator battery, which is used to start up the generator.

The control panel provides a user interface of the generator to manage and control its operation.

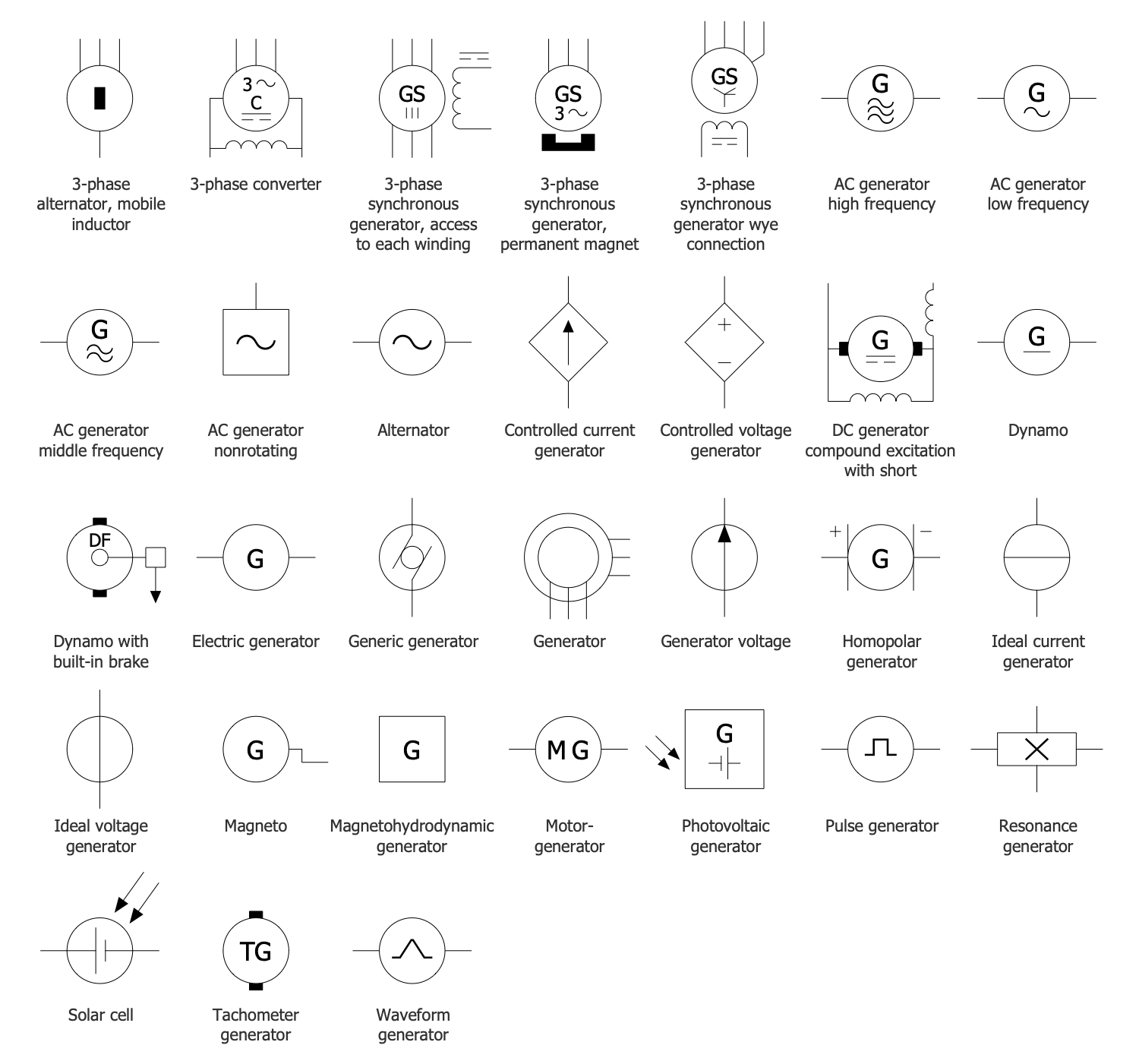

Example 2. Electric Generators Library Design Elements

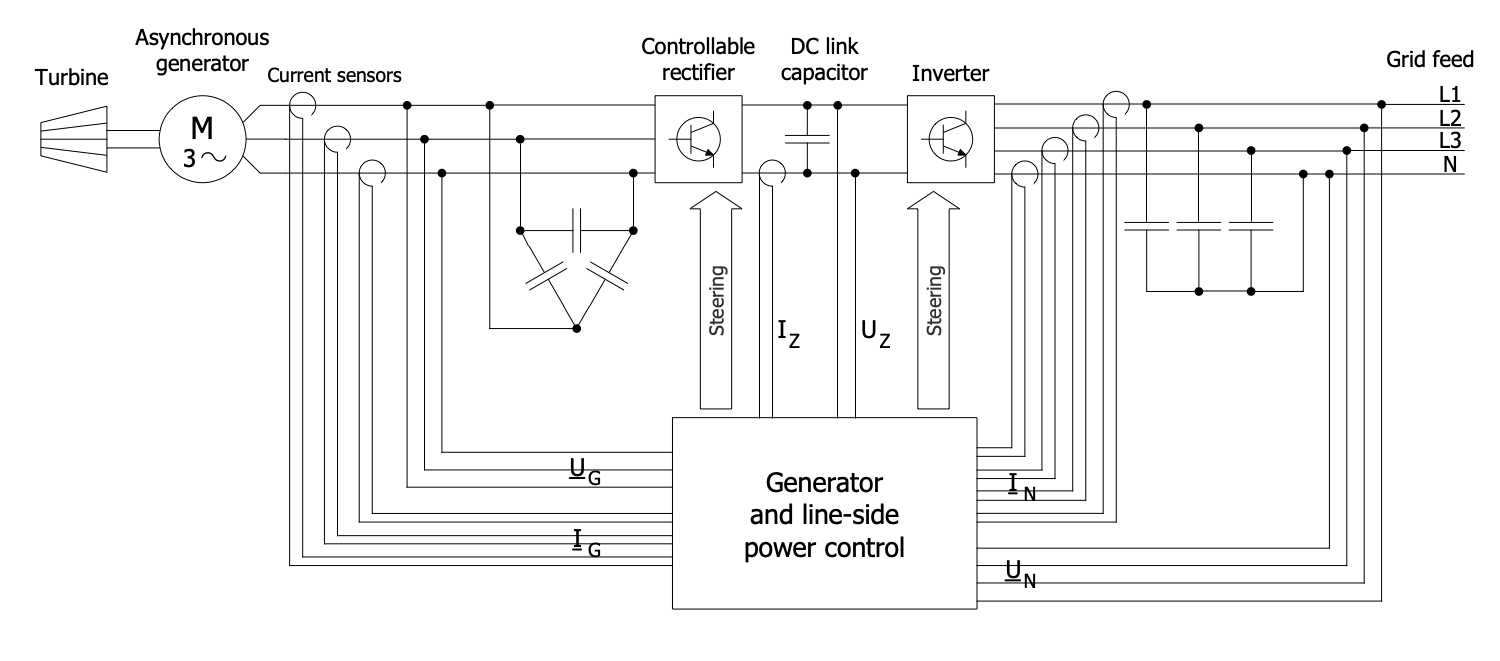

ConceptDraw DIAGRAM software extended with the Power Сircuits solution is ideal for electrical engineering, development of electric generators and other electrical and electronic equipment. It includes a variety of pre-made professional-looking samples and a collection of predesigned vector design symbols and clipart for easy designing induction generator circuit diagram, schematic of double fed induction generator connected to a wind turbine, and many more other simple and complex generators.

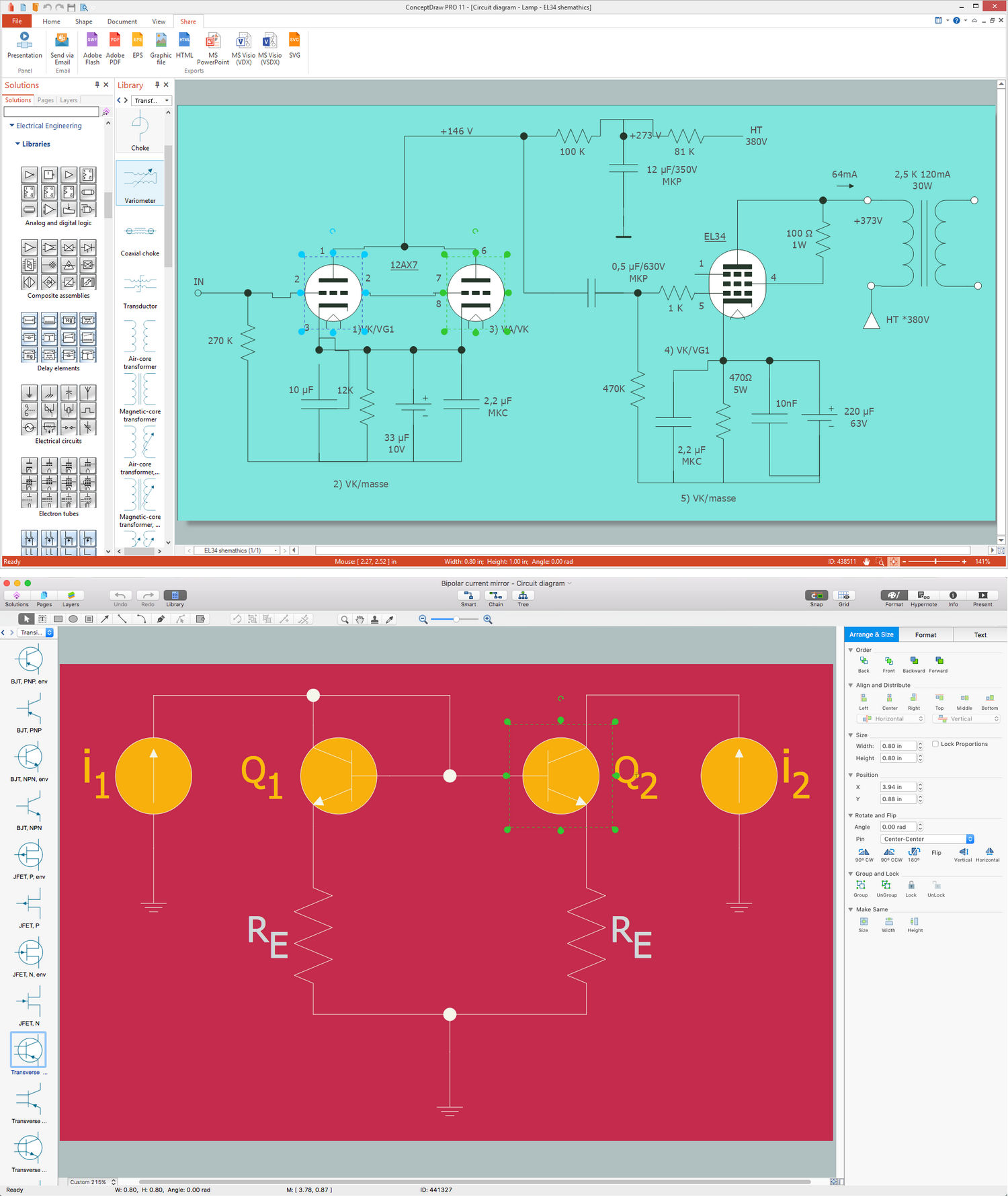

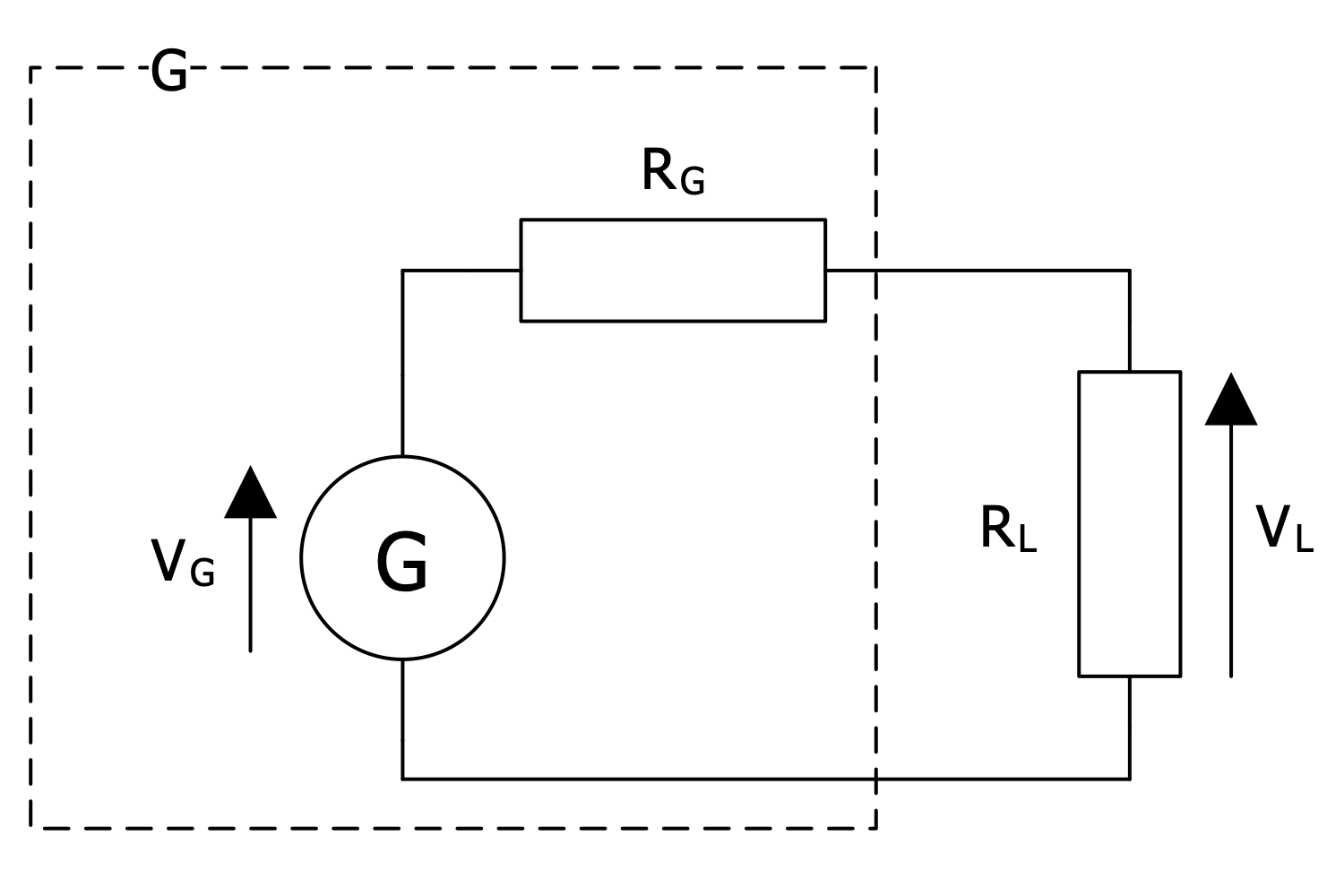

Example 3. Generator and Load Equivalent Circuit

The Electrical circuit samples you see on this page were created in ConceptDraw DIAGRAM software using the drawing tools of the Power Сircuits Solution. These examples successfully demonstrate the solution's capabilities and the professional results you can achieve using it. An experienced user spent 5-10 minutes creating each of these samples.

Use the drawing tools of the Power Сircuits solution to design your own Electrical Circuit diagrams, schematics, and layouts quick, easy, and effective.

All source documents are vector graphic documents. They are available for reviewing, modifying, or converting to a variety of formats (PDF file, MS PowerPoint, MS Visio, and many other graphic formats) from the ConceptDraw STORE. The Power Сircuits Solution is available for ConceptDraw DIAGRAM users.