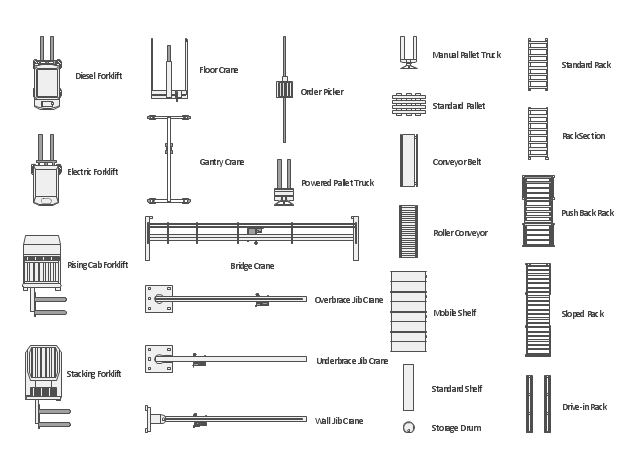

The vector stencils library "Storage and distribution" contains 24 symbols of storage and distribution industrial equipment.

Use the design elements library "Storage and distribution" to draw industrial warehouse plans and storage and distribution equipment layouts using the ConceptDraw PRO diagramming and vector drawing software.

"A warehouse is a commercial building for storage of goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial areas of cities and towns and villages. They usually have loading docks to load and unload goods from trucks. Sometimes warehouses are designed for the loading and unloading of goods directly from railways, airports, or seaports. They often have cranes and forklifts for moving goods, which are usually placed on ISO standard pallets loaded into pallet racks.

Some of the most common warehouse storage systems are:

Pallet racking including selective, drive-in, drive-thru, double-deep, pushback, and gravity flow;

Mezzanine including structural, roll formed, racks;

Vertical Lift Modules;

Horizontal Carousels;

Vertical Carousels." [Warehouse. Wikipedia]

The shapes library "Storage and distribution" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

Use the design elements library "Storage and distribution" to draw industrial warehouse plans and storage and distribution equipment layouts using the ConceptDraw PRO diagramming and vector drawing software.

"A warehouse is a commercial building for storage of goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial areas of cities and towns and villages. They usually have loading docks to load and unload goods from trucks. Sometimes warehouses are designed for the loading and unloading of goods directly from railways, airports, or seaports. They often have cranes and forklifts for moving goods, which are usually placed on ISO standard pallets loaded into pallet racks.

Some of the most common warehouse storage systems are:

Pallet racking including selective, drive-in, drive-thru, double-deep, pushback, and gravity flow;

Mezzanine including structural, roll formed, racks;

Vertical Lift Modules;

Horizontal Carousels;

Vertical Carousels." [Warehouse. Wikipedia]

The shapes library "Storage and distribution" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

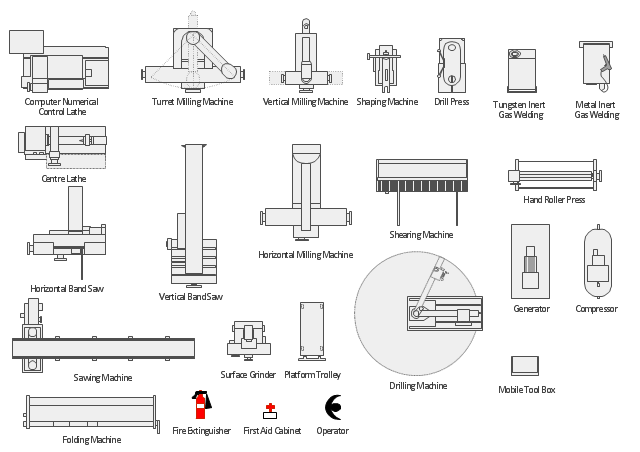

The vector stencils library "Machines and equipment" contains 24 symbols of industrial machines and equipment.

Use the design elements library "Machines and equipment" for drawing plant interior design plans, manufacturing equipment layouts and factory floor plans using the ConceptDraw PRO diagramming and vector drawing software.

"Manufacturing is the production of goods for use or sale using labor and machines, tools, chemical and biological processing, or formulation. The term may refer to a range of human activity, from handicraft to high tech, but is most commonly applied to industrial production, in which raw materials are transformed into finished goods on a large scale.

Modern manufacturing includes all intermediate processes required for the production and integration of a product's components. Some industries, such as semiconductor and steel manufacturers use the term fabrication instead.

The manufacturing sector is closely connected with engineering and industrial design." [Manufacturing. Wikipedia]

The shapes library "Machines and equipment" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

Use the design elements library "Machines and equipment" for drawing plant interior design plans, manufacturing equipment layouts and factory floor plans using the ConceptDraw PRO diagramming and vector drawing software.

"Manufacturing is the production of goods for use or sale using labor and machines, tools, chemical and biological processing, or formulation. The term may refer to a range of human activity, from handicraft to high tech, but is most commonly applied to industrial production, in which raw materials are transformed into finished goods on a large scale.

Modern manufacturing includes all intermediate processes required for the production and integration of a product's components. Some industries, such as semiconductor and steel manufacturers use the term fabrication instead.

The manufacturing sector is closely connected with engineering and industrial design." [Manufacturing. Wikipedia]

The shapes library "Machines and equipment" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

HelpDesk

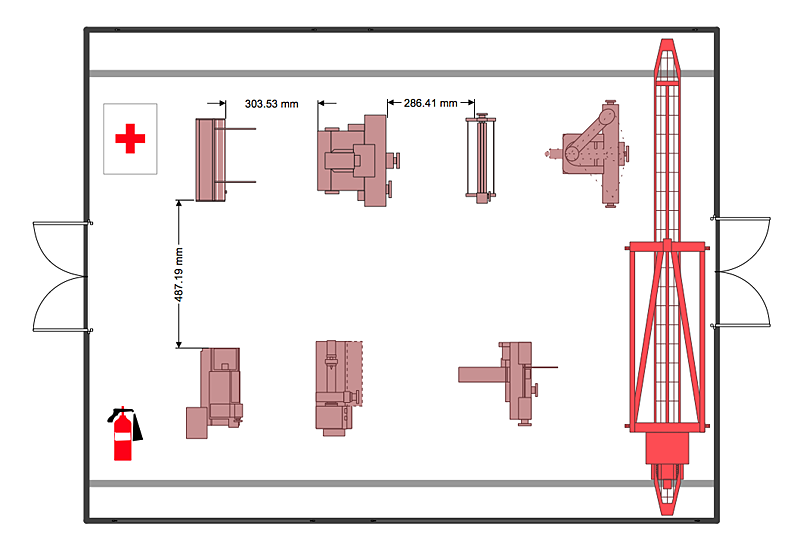

How to Create a Plant Layout Design

A plant construction process begins from a plant layout stage - an engineering stage used to design, analyze and finally choose the suitable configurations for a manufacturing plant. Plant Layout issues are core to any enterprise and are challenged in all types of manufacturing process. The sufficiency of layout influences the efficiency of subsequent operations. It is an important background for efficient manufacturing and also has a great deal with many questions. Once the place of the plant has been determined, the next important task before the management of the plant is to plan appropriate layout for the enterprise. Plant layout is used to create the most effective physical arrangement of machinery and equipment, with the plant building in such a manner so as to make quickest and cheapest way from a raw material to the shipment of the completed product Making a plan that shows the location of industrial equipment involves many different elements that can be managed using ConThe vector stencils library "Shipping and receiving" contains 18 symbols of industrial shipping and receiving equipment.

Use the design elements library "Shipping and receiving" to draw factory warehouse equipment layout plans, floor plans of shipping and receiving centers with equipment for hauling, transporting, and distributing manufactured goods, freight, cargo, and stock from plants and industrial facilities using the ConceptDraw PRO diagramming and vector drawing software.

"Freight transport, or shipping, is a key in the value chain in manufacturing.

While all modes of transport are used for cargo transport, there is high differentiation between the nature of the cargo transport, in which mode is chosen.

Logistics refers to the entire process of transferring products from producer to consumer, including storage, transport, transshipment, warehousing, material-handling and packaging, with associated exchange of information.

Containerization, with the standardization of ISO containers on all vehicles and at all ports, has revolutionized international and domestic trade, offering huge reduction in transshipment costs. Traditionally, all cargo had to be manually loaded and unloaded into the haul of any ship or car; containerization allows for automated handling and transfer between modes, and the standardized sizes allow for gains in economy of scale in vehicle operation." [Transport. Freight.

Wikipedia]

This shapes library "Shipping and receiving" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

Use the design elements library "Shipping and receiving" to draw factory warehouse equipment layout plans, floor plans of shipping and receiving centers with equipment for hauling, transporting, and distributing manufactured goods, freight, cargo, and stock from plants and industrial facilities using the ConceptDraw PRO diagramming and vector drawing software.

"Freight transport, or shipping, is a key in the value chain in manufacturing.

While all modes of transport are used for cargo transport, there is high differentiation between the nature of the cargo transport, in which mode is chosen.

Logistics refers to the entire process of transferring products from producer to consumer, including storage, transport, transshipment, warehousing, material-handling and packaging, with associated exchange of information.

Containerization, with the standardization of ISO containers on all vehicles and at all ports, has revolutionized international and domestic trade, offering huge reduction in transshipment costs. Traditionally, all cargo had to be manually loaded and unloaded into the haul of any ship or car; containerization allows for automated handling and transfer between modes, and the standardized sizes allow for gains in economy of scale in vehicle operation." [Transport. Freight.

Wikipedia]

This shapes library "Shipping and receiving" is included in the Plant Layout Plans solution from the Building Plans area of ConceptDraw Solution Park.

IDEF Business Process Diagrams

IDEF Business Process Diagrams

Use the IDEF Business Process Diagrams solution to create effective database designs and object-oriented designs, following the integration definition methodology.

- Symbol For Plant Layout In Steel Factory

- Symbols Used For Fire Extinguisher In Food Plant Design And Layout

- Design elements - HVAC equipment | Plant Layout Plans | ATM UML ...

- Flow chart Example. Warehouse Flowchart | Business Process ...

- Plant Layout Plans | ATM UML Diagrams | Hotel Plan. Hotel Plan ...

- Symbols Used For Pump In Food Plant Design And Layout

- Symbols Used In Layout Making Of Industry

- Plant Layout Plans | How to Create a Plant Layout Design | Plant ...

- Plant Layout Plans | Factory layout floor plan | Emergency Plan ...

- Computers and Communications | Mechanical Drawing Symbols ...

- Plant Layout Of Factory Machines

- Plant Symbols Used In Site Plans

- Warehouse layout floor plan | Warehouse with conveyor system ...

- Design elements - Stations | Plant Layout Plans | Design elements ...

- Mechanical Drawing Symbols | FSM — Finite-state Machine | Plant ...

- Flow chart Example. Warehouse Flowchart | Plant Layout Plans ...

- Piping and Instrumentation Diagram Software | Plant Layout Plans ...

- Plant Layout Plans | Process Flowchart | Floor Plans Of An Industry ...

- Basic Flowchart Symbols and Meaning | Plant Layout Plans | Flow ...

- Elements Of Plant Layout