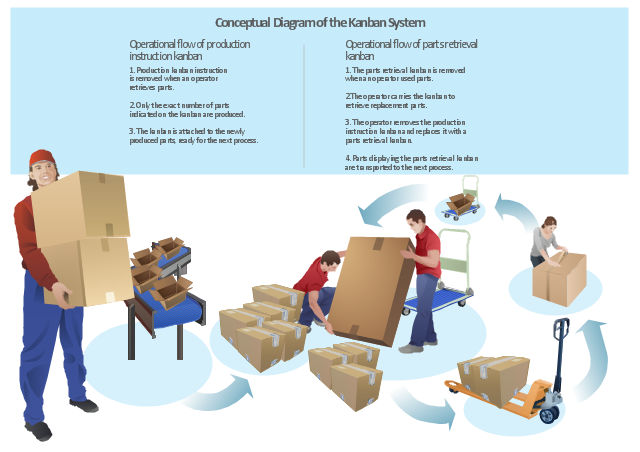

"Kanban ... (literally signboard or billboard) is a scheduling system for lean and just-in-time (JIT) production. Kanban is a system to control the logistical chain from a production point of view, and is not an inventory control system. Kanban was developed by Taiichi Ohno, at Toyota, to find a system to improve and maintain a high level of production. Kanban is one method through which JIT is achieved.

Kanban became an effective tool in support of running a production system as a whole, and it proved to be an excellent way for promoting improvement. Problem areas were highlighted by reducing the number of kanban in circulation." [Kanban. Wikipedia]

The example "Conceptual diagram of the Kanban System" was created in the ConceptDraw PRO diagramming and vector drawing software using the vector stencils library Packaging, loading, customs.

The example "Conceptual diagram of the Kanban System" is included in the Manufacturing and Maintenance solution from the Illustration area of ConceptDraw Solution Park.

Kanban became an effective tool in support of running a production system as a whole, and it proved to be an excellent way for promoting improvement. Problem areas were highlighted by reducing the number of kanban in circulation." [Kanban. Wikipedia]

The example "Conceptual diagram of the Kanban System" was created in the ConceptDraw PRO diagramming and vector drawing software using the vector stencils library Packaging, loading, customs.

The example "Conceptual diagram of the Kanban System" is included in the Manufacturing and Maintenance solution from the Illustration area of ConceptDraw Solution Park.

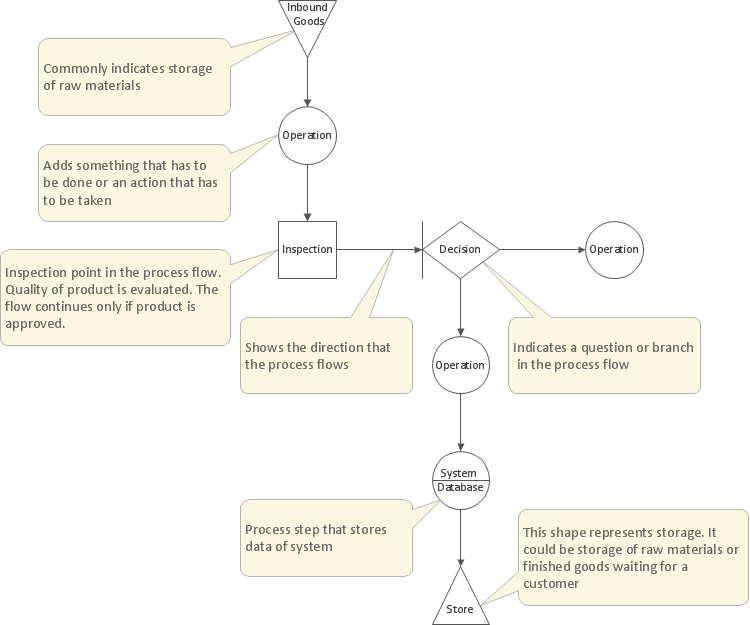

Management Tools — Total Quality Management

The Total Quality Management Diagram solution helps your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.- Jit Model Diagram

- Block Diagram Of Toyota Jit System

- Jit Block Diagram

- Basic Flowchart Symbols and Meaning | Conceptual diagram of the ...

- Jit System With Flow Chart

- Conceptual diagram of the Kanban System | Gambar Area Diagram

- Conceptual diagram of the Kanban System | Kanban Board ...

- Manufacturing 8 Ms fishbone diagram - Template | Process ...

- Kanban Board Software | Conceptual diagram of the Kanban ...

- Management Tools — Total Quality Management | Jit Tqm Tpm

- Conceptual diagram of the Kanban System | Manufacturing and ...

- Conceptual diagram of the Kanban System | IDEF1 standard ...

- Conceptual diagram of the Kanban System | Gambar Conceptual ...

- Flow chart Example. Warehouse Flowchart | Conceptual diagram of ...

- Conceptual diagram of the Kanban System | Gambar Diagram Process

- Conceptual diagram of the Kanban System | Value stream mapping ...

- Value stream with ConceptDraw PRO | Circular arrows diagram ...

- Flow chart Example. Warehouse Flowchart | Conceptual diagram of ...

- Warehouse with conveyor system - Floor plan | Conceptual diagram ...

- Data Flow Diagram Model | Peru wheat area and production | 4 Ms ...