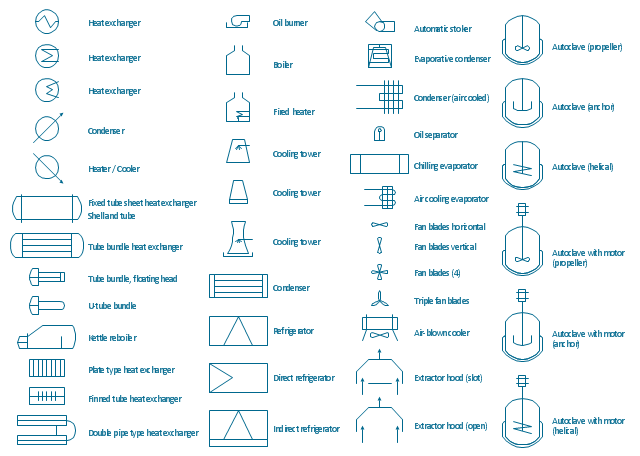

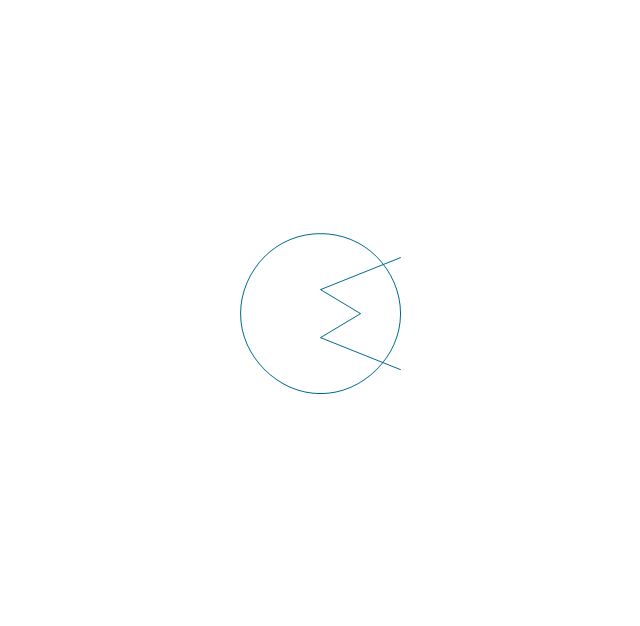

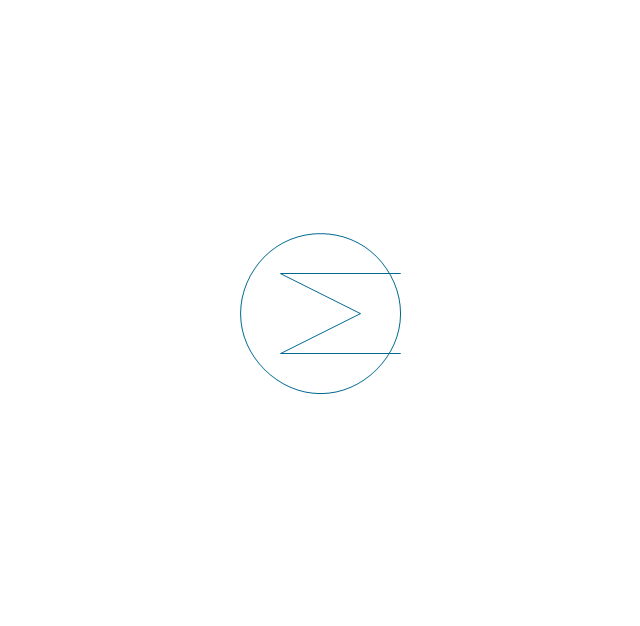

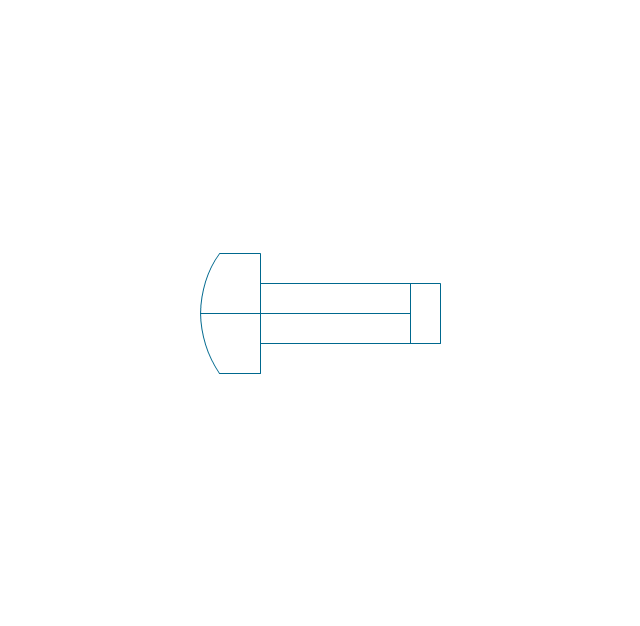

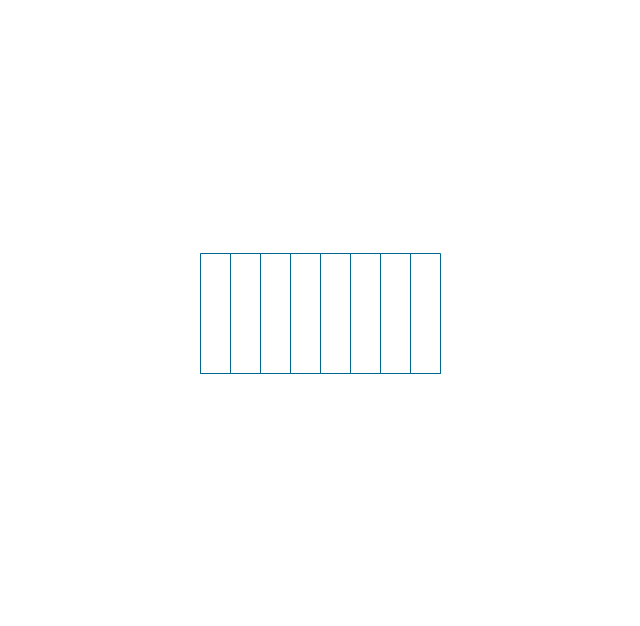

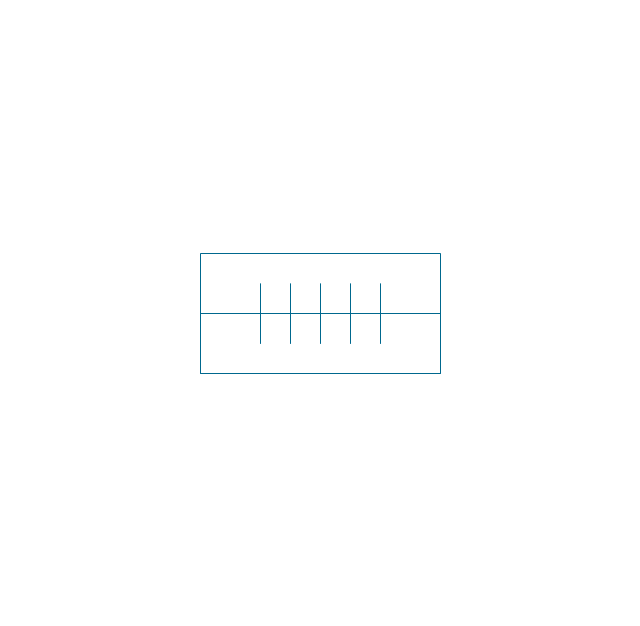

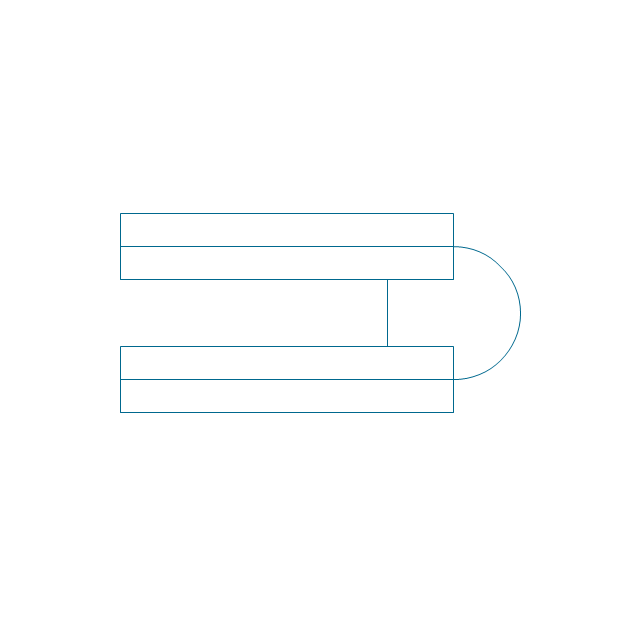

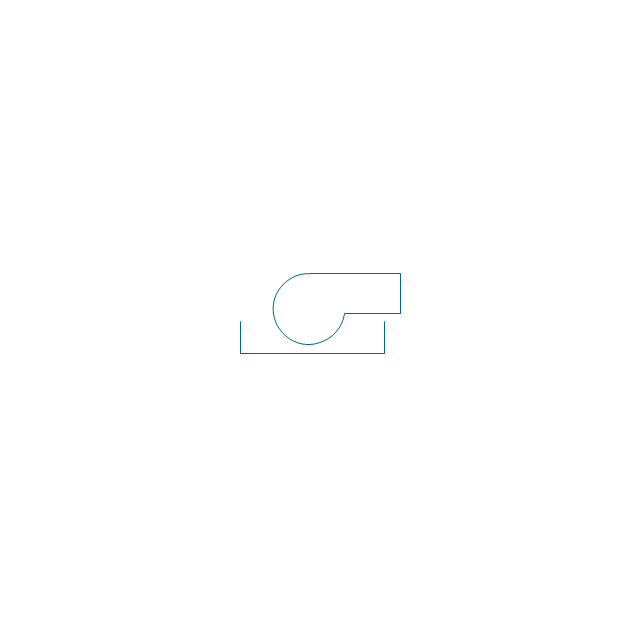

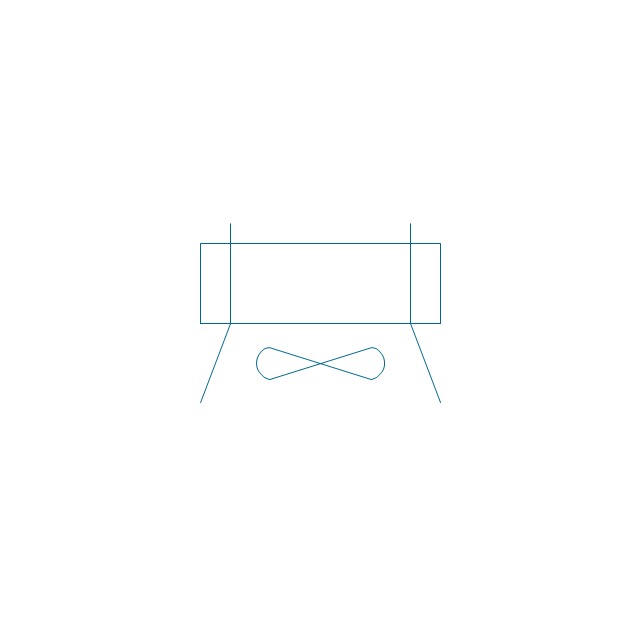

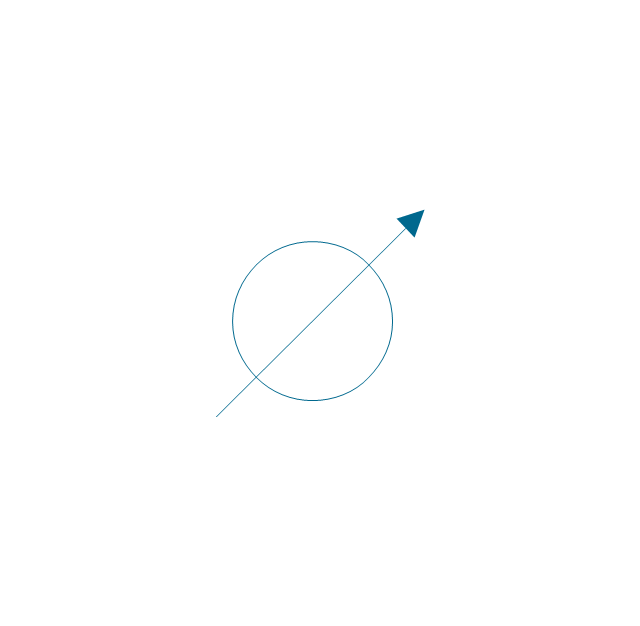

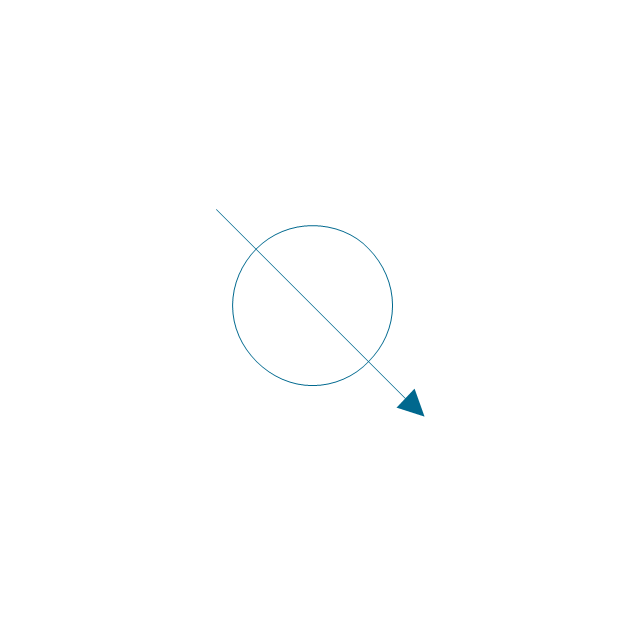

The vector stencils library "Heating equipment" contains 42 symbols of regenerators, intercoolers, heaters, and condensers.

Use these shapes for drawing cooling systems, heat recovery systems, thermal, heat transfer and mechanical design, and process flow diagrams (PFD).

"Heating or cooling of processes, equipment, or enclosed environments are within the purview of thermal engineering.

One or more of the following disciplines may be involved in solving a particular thermal engineering problem:

Thermodynamics,

Fluid mechanics,

Heat transfer,

Mass transfer.

Thermal engineering may be practiced by mechanical engineers and chemical engineers.

One branch of knowledge used frequently in thermal engineering is that of thermofluids." [Thermal engineering. Wikipedia]

The design elements example "Heating equipment" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Engineering area of ConceptDraw Solution Park.

Use these shapes for drawing cooling systems, heat recovery systems, thermal, heat transfer and mechanical design, and process flow diagrams (PFD).

"Heating or cooling of processes, equipment, or enclosed environments are within the purview of thermal engineering.

One or more of the following disciplines may be involved in solving a particular thermal engineering problem:

Thermodynamics,

Fluid mechanics,

Heat transfer,

Mass transfer.

Thermal engineering may be practiced by mechanical engineers and chemical engineers.

One branch of knowledge used frequently in thermal engineering is that of thermofluids." [Thermal engineering. Wikipedia]

The design elements example "Heating equipment" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Engineering area of ConceptDraw Solution Park.

Chemical and Process Engineering

Chemical and Process Engineering

This chemical engineering solution extends ConceptDraw PRO v.9.5 (or later) with process flow diagram symbols, samples, process diagrams templates and libraries of design elements for creating process and instrumentation diagrams, block flow diagrams (BFD

The vector stencils library "Heating equipment" contains 42 symbols of regenerators, intercoolers, heaters, and condensers.

Use these shapes for drawing cooling systems, heat recovery systems, thermal, heat transfer and mechanical design, and process flow diagrams (PFD) in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-chemical-process

Use these shapes for drawing cooling systems, heat recovery systems, thermal, heat transfer and mechanical design, and process flow diagrams (PFD) in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

www.conceptdraw.com/ solution-park/ engineering-chemical-process

HVAC Plans

HVAC Plans

Use HVAC Plans solution to create professional, clear and vivid HVAC-systems design plans, which represent effectively your HVAC marketing plan ideas, develop plans for modern ventilation units, central air heaters, to display the refrigeration systems for automated buildings control, environmental control, and energy systems.

This process flow diagram (PFD) of a typical crude oil distillation unit as used in petroleum crude oil refineries was redrawn from Wikipedia file: Crude Oil Distillation Unit.png. [en.wikipedia.org/ wiki/ File:Crude_ Oil_ Distillation_ Unit.png]

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"An oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene and liquefied petroleum gas. Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids between large chemical processing units. In many ways, oil refineries use much of the technology of, and can be thought of, as types of chemical plants. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot (tank farm) at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products.

An oil refinery is considered an essential part of the midstream side of the petroleum industry." [en.wikipedia.org/ wiki/ Oil_ refinery]

The process flow diagram (PFD) example "Crude oil distillation" was drawn using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

This file is licensed under the Creative Commons Attribution-Share Alike 3.0 Unported license. [creativecommons.org/ licenses/ by-sa/ 3.0/ deed.en]

"An oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene and liquefied petroleum gas. Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids between large chemical processing units. In many ways, oil refineries use much of the technology of, and can be thought of, as types of chemical plants. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot (tank farm) at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products.

An oil refinery is considered an essential part of the midstream side of the petroleum industry." [en.wikipedia.org/ wiki/ Oil_ refinery]

The process flow diagram (PFD) example "Crude oil distillation" was drawn using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park.

- Heating Apparatus Chemistry Diagram

- Sketch A Well Label Diagram Of Heat Apparatus

- Exsmple Of Heating Apparatus And Duagran

- Diagram Of Laboratory Heating Apparatus

- Heat Apparatus In The Lab Diagram

- Laboratory equipment - Vector stencils library | Heating Mantle ...

- Laboratory equipment - Vector stencils library | Diagram Of A ...

- Amine treating unit schematic diagram | Heating equipment - Vector ...

- Cross-Functional Flowchart | Heating equipment - Vector stencils ...

- Process Flow Diagram Symbols | Design elements - Heating ...

- Design elements - Heating equipment | Piping and Instrumentation ...

- Diagram Of Laboratory Apparatus Heat Energy

- Chemical engineering - Vector stencils library | Heating equipment ...

- Design elements - Heating equipment | Process Flow Diagram ...

- Heating equipment - Vector stencils library | Design elements ...

- Draw A Well Labelled Diagram Of The Heating Apparatus

- Heating equipment - Vector stencils library | HVAC Plans | Process ...

- Oil Process Heater Diagram

- Process Flow Diagram Symbols | Chemical and Process ...

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-heating-equipment---vector-stencils-library.png--diagram-flowchart-example.png)

-crude-oil-distillation-unit---pfd.png--diagram-flowchart-example.png)