PM Easy

PM Easy

This solution extends ConceptDraw PROJECT software with the ability to quickly start a project; it lists task relationships and dependencies to make iterative planning easy.

Health Food

Health Food

The Health Food solution contains the set of professionally designed samples and large collection of vector graphic libraries of healthy foods symbols of fruits, vegetables, herbs, nuts, beans, seafood, meat, dairy foods, drinks, which give powerful possi

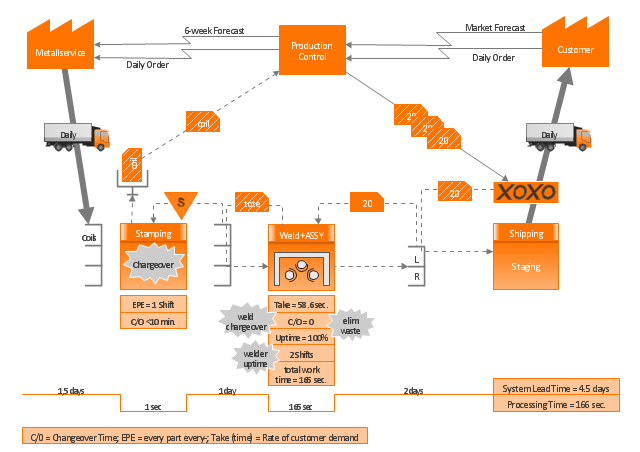

"Value Stream Map (VSM)

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

1. A tool used to improve a process by identifying added value and eliminating waste.

2. A process map that follows the value creation process.

A. “strap yourself to the product (or service) and see where you go”

3. A process map with data added.

A. Times: processing, wait, cycle.

B. Quality: number of rejects.

C. Inventory.

D. Resources.

1) Number of people.

2) Space.

3) Distance traveled.

E. Whatever else is useful for analyzing the process." [ocw.mit.edu/ courses/ aeronautics-and-astronautics/ 16-660j-introduction-to-lean-six-sigma-methods-january-iap-2012/ lecture-notes/ MIT16_ 660JIAP12_ 1-6.pdf]

This sample VSM flowchart shows the value stream in a manufacturing, production control and shipping processes.

This value stream mapping diagram example was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Value Stream Mapping solution from the Quality area of ConceptDraw Solution Park.

- Material Requisition Flowchart . Flowchart Examples | Value stream ...

- Value stream mapping - Vector stencils library | Contoh Flowchart ...

- Value stream mapping - Vector stencils library | Flow chart Example ...

- Material Requisition Flowchart . Flowchart Examples | Value stream ...

- Taxi Service Data Flow Diagram DFD Example | Business Process ...

- Truck Transportation Business Flow Chart

- Business Process Flowchart Symbols | Flowchart Components ...

- Draw And Leveling The Communication Pyramid

- Material Requisition Flowchart . Flowchart Examples | Process ...

- Process Flow Chart For Freight And Vehicles Control

- Process Flowchart | Value stream mapping - Vector stencils library ...

- Process Flowchart | How to Create a Data Flow Diagram using ...

- Basic Flowchart Symbols and Meaning | Types of Flowchart ...

- How to Make an Accounting Process Flowchart | Purchase Process ...

- Process Flowchart | Flow chart Example. Warehouse Flowchart ...

- Account Flowchart Stockbridge System. Flowchart Examples | Data ...

- Business Process Flowchart Symbols | Process Flowchart | Event ...

- Business Process Mapping — How to Map a Work Process ...

- Process Flowchart | Flow chart Example. Warehouse Flowchart ...