Plant Layout Plans

Plant Layout Plans

Plant Layout Plans solution can be used for power plant design and plant layout design, for making the needed building plant plans and plant layouts looking professionally good. Having the newest plant layout software, the plant design solutions and in particular the ConceptDraw’s Plant Layout Plans solution, including the pre-made templates, examples of the plant layout plans, and the stencil libraries with the design elements, the architects, electricians, interior designers, builders, telecommunications managers, plant design engineers, and other technicians can use them to create the professionally looking drawings within only a few minutes.

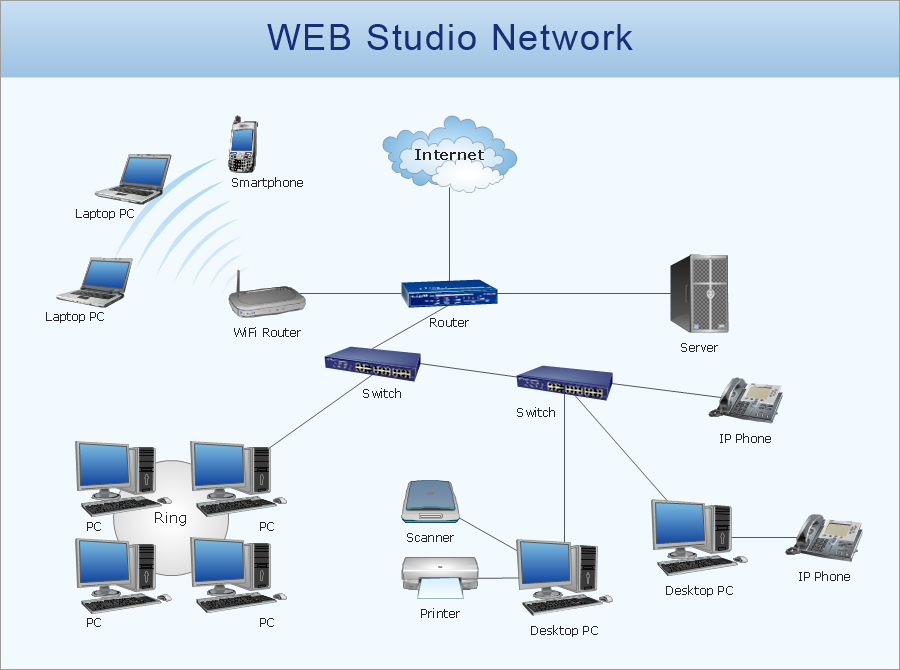

Network Diagram Software

Network Diagrams are used to visually represent the network architecture, to illustrate the network structure, how the computers and other elements of the network are connected each other using a variety of network symbols, clipart and connection lines. They are incredibly useful on the stages of projecting computer network, of its construction and exploitation. Professionally designed and accurate Network Diagrams are equally convenient for computer engineers and users. You can construct them by hand on the paper or use special network diagramming software, such as ConceptDraw DIAGRAM. Having at disposal the powerful network diagramming tools of Computer Network Diagrams solution included to ConceptDraw Solution Park, you can succeed in drawing various types of Computer Network Diagrams, among them Network Communication Plans, Logical Network Diagrams, Network Topology Diagrams, LAN and WAN Diagrams, Network Floor Plan Layouts, Computer Network System Diagrams, Web-based Network Diagrams, Wireless Network Diagrams, Cisco Network Diagram, and others.

HelpDesk

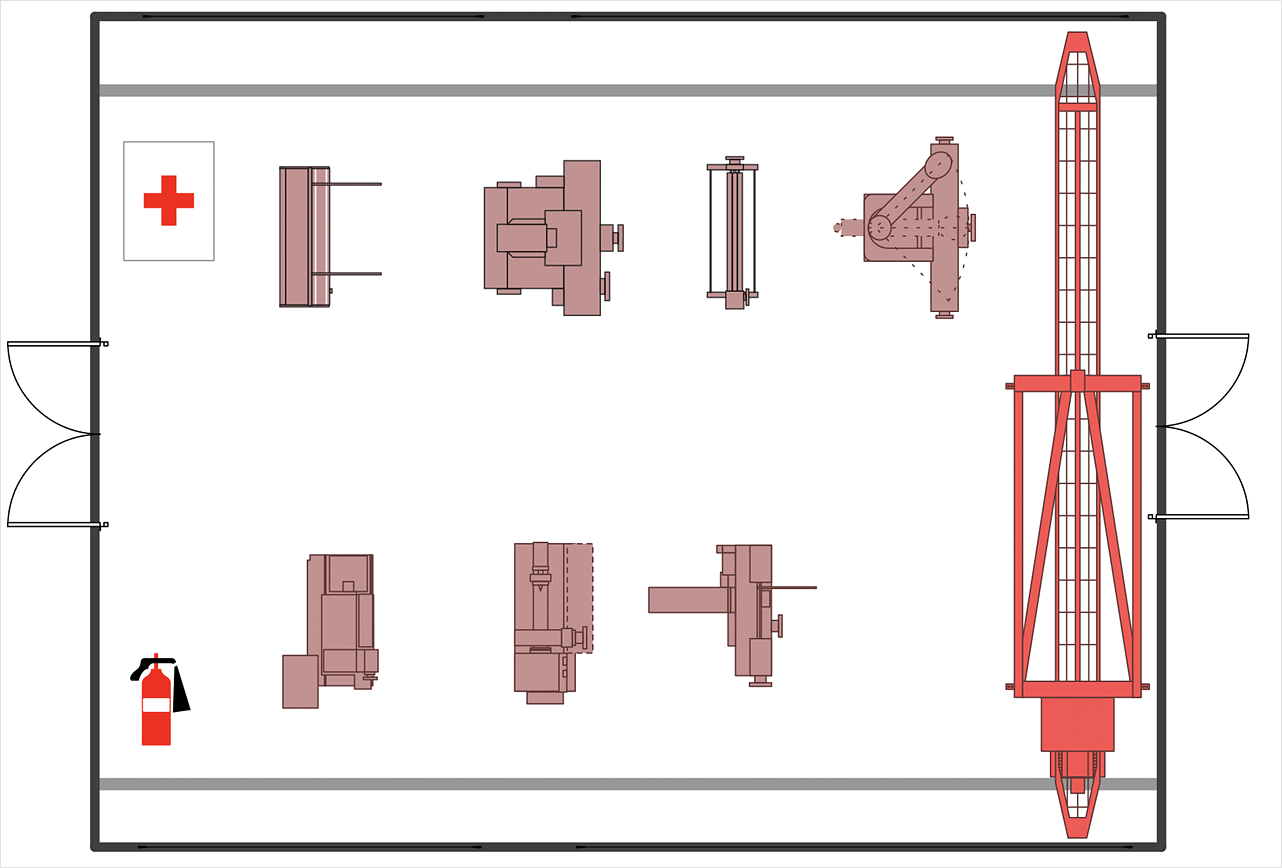

How to Create a Plant Layout Design

A plant construction process begins from a plant layout stage - an engineering stage used to design, analyze and finally choose the suitable configurations for a manufacturing plant. Plant Layout issues are core to any enterprise and are challenged in all types of manufacturing process. The sufficiency of layout influences the efficiency of subsequent operations. It is an important background for efficient manufacturing and also has a great deal with many questions. Once the place of the plant has been determined, the next important task before the management of the plant is to plan appropriate layout for the enterprise. Plant layout is used to create the most effective physical arrangement of machinery and equipment, with the plant building in such a manner so as to make quickest and cheapest way from a raw material to the shipment of the completed product Making a plan that shows the location of industrial equipment involves many different elements that can be managed using Con- Plant Layout Plans | Plant Design Solutions | How to Create a Plant ...

- Factory layout floor plan | Plant Layout Plans | Restaurant Floor ...

- Industrial Layout Plan

- Industrial Engineering Layout Software

- Plant Layout Plans | CAD Drawing Software for Making Mechanic ...

- Factory layout floor plan | Building Drawing Software for Designing ...

- How Can Draw Floor Industrial Layout

- Plant Layout Plans | Factory layout floor plan | How to Create a Plant ...

- Industrial Plant Drawing

- Draw Factory Layout Design Of Pharmaceutical Industry

- Templates In Making Plant Layout In Industrial Engineering

- Process Flowchart | Technical Drawing Software | Plant Layout ...

- Industrial Layout Maker

- Plant Layout Plans | Building Drawing Software for Design Site Plan ...

- Factory layout floor plan | Plant Layout Plans | Building Drawing ...

- Cafe Floor Plan Design Software | Building Drawing Software for ...

- How To Draw Building Plans | Building Drawing Design Element ...

- Factory layout floor plan | Cafe Floor Plan Design Software | Building ...

- How To Draw Industrial Diesel Generator Layout Diagram

- Factory layout floor plan | CAD Software for Architectural Designs ...