Engineering

Engineering

This solution extends ConceptDraw PRO v9.4 with the ability to visualize industrial systems in electronics, electrical, chemical, process, and mechanical engineering.

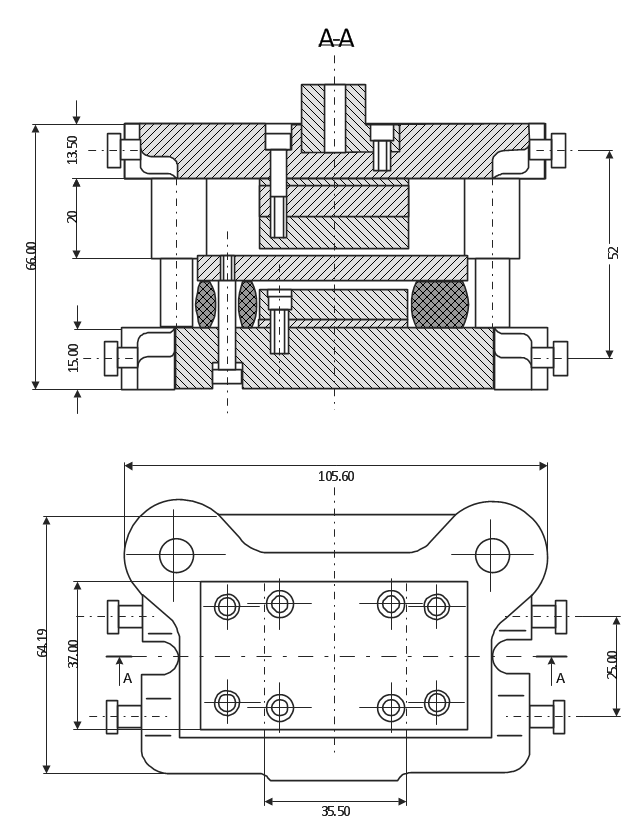

This technical drawing shows the machine parts assembly using joining by threaded fasteners.

"Assembling (joining of the pieces) is done by welding, binding with adhesives, riveting, threaded fasteners, or even yet more bending in the form of a crimped seam. Structural steel and sheet metal are the usual starting materials for fabrication, along with the welding wire, flux, and fasteners that will join the cut pieces. As with other manufacturing processes, both human labor and automation are commonly used. The product resulting from fabrication may be called a fabrication. Shops that specialize in this type of metal work are called fab shops. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication." [Metal fabrication. Wikipedia]

This mechanical engineering drawing example was designed using ConceptDraw PRO diagramming and vector drawing software extended with Mechanical Engineering solution from Engineering area of ConceptDraw Solution Park.

"Assembling (joining of the pieces) is done by welding, binding with adhesives, riveting, threaded fasteners, or even yet more bending in the form of a crimped seam. Structural steel and sheet metal are the usual starting materials for fabrication, along with the welding wire, flux, and fasteners that will join the cut pieces. As with other manufacturing processes, both human labor and automation are commonly used. The product resulting from fabrication may be called a fabrication. Shops that specialize in this type of metal work are called fab shops. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication." [Metal fabrication. Wikipedia]

This mechanical engineering drawing example was designed using ConceptDraw PRO diagramming and vector drawing software extended with Mechanical Engineering solution from Engineering area of ConceptDraw Solution Park.

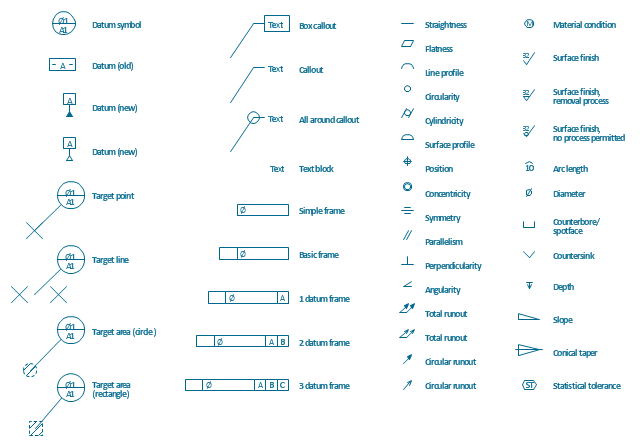

The vector stencils library "Dimensioning and tolerancing" contains 45 symbols of geometric dimensions and mechanical tolerances, geometric symbols, callouts, and text boxes and inserts.

Use these geometric dimensioning and tolerancing (GD&T) shapes to create annotated mechanical drawings.

"Geometric dimensioning and tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describes nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features." [Geometric dimensioning and tolerancing. Wikipedia]

The shapes example "Design elements - Dimensioning and tolerancing" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Mechanical Engineering solution from the ConceptDraw Solution Park.

Use these geometric dimensioning and tolerancing (GD&T) shapes to create annotated mechanical drawings.

"Geometric dimensioning and tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describes nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features." [Geometric dimensioning and tolerancing. Wikipedia]

The shapes example "Design elements - Dimensioning and tolerancing" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Mechanical Engineering solution from the ConceptDraw Solution Park.

- Mechanical Drawing Symbols | Technical drawing - Machine parts ...

- Technical drawing - Machine

- Mechanical Drawing Symbols | Process Flowchart | Engineering ...

- Mechanical Drawing Symbols | Engineering | UML State Machine ...

- Mechanical Drawing Symbols | Engineering | Technical Drawing ...

- Mechanical Drawing Symbols | UML State Machine Diagram.Design ...

- Engineering Machine Drawing Assemble Mech

- Technical Drawing Software | How to Create a Mechanical Diagram ...

- Mechanical Drawing Symbols | Mechanical Engineering | How to ...

- Mechanical Engineering Drawing Assembly

- Mechanical Drawing Symbols | Mechanical Engineering | Technical ...

- Technical drawing - Machine parts assembling | Flow chart Example ...

- Mechanical Drawing Symbols | State Machine Diagram ...

- Mechanical Drawing Symbols | UML State Machine Diagram.Design ...

- Mechanical Engineering | Engineering | Mechanical Drawing ...

- Mechanical Drawing Symbols | Technical Drawing Software ...

- Technical drawing - Machine parts assembling | Technical Drawing ...

- Mechanical Drawing Symbols | Technical Drawing Software ...

- Mechanical Drawing Symbols | Process Flowchart | Technical ...

- Mechanical Drawing Symbols | Process Flowchart | Flow chart ...