What is Value Stream Mapping?

Value stream maps (VSM) are an essential tool for organizations applying Lean methods.Lean Manufacturing Diagrams

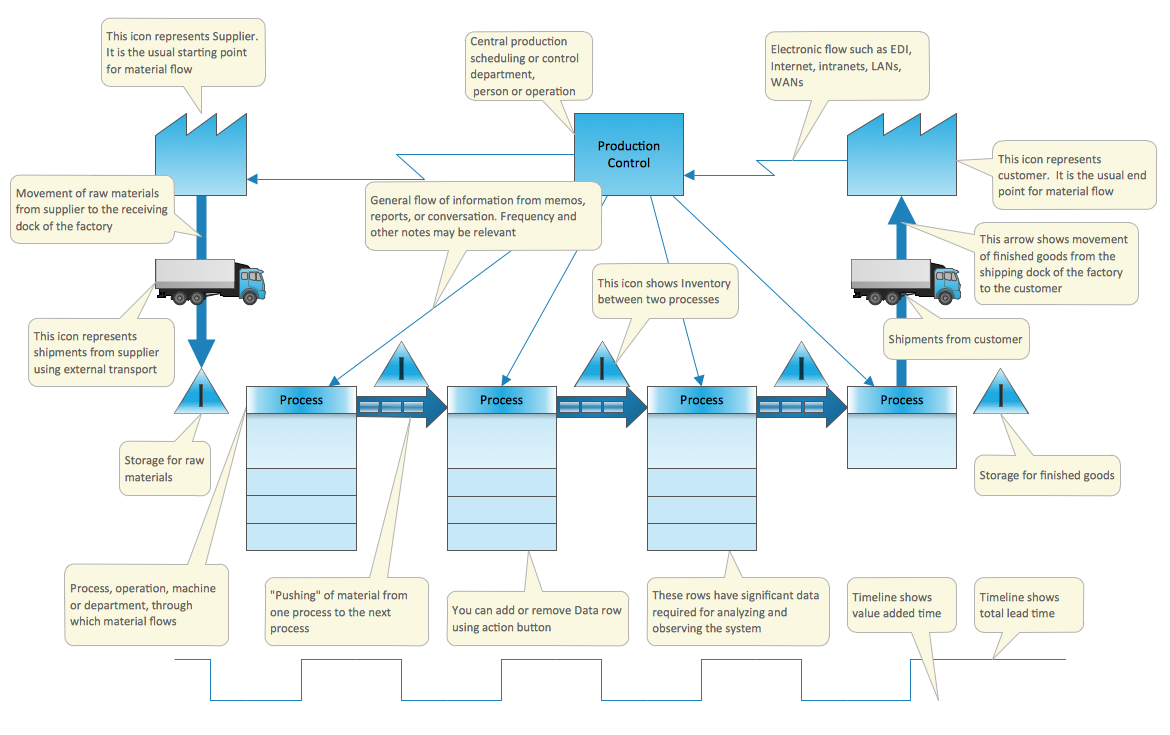

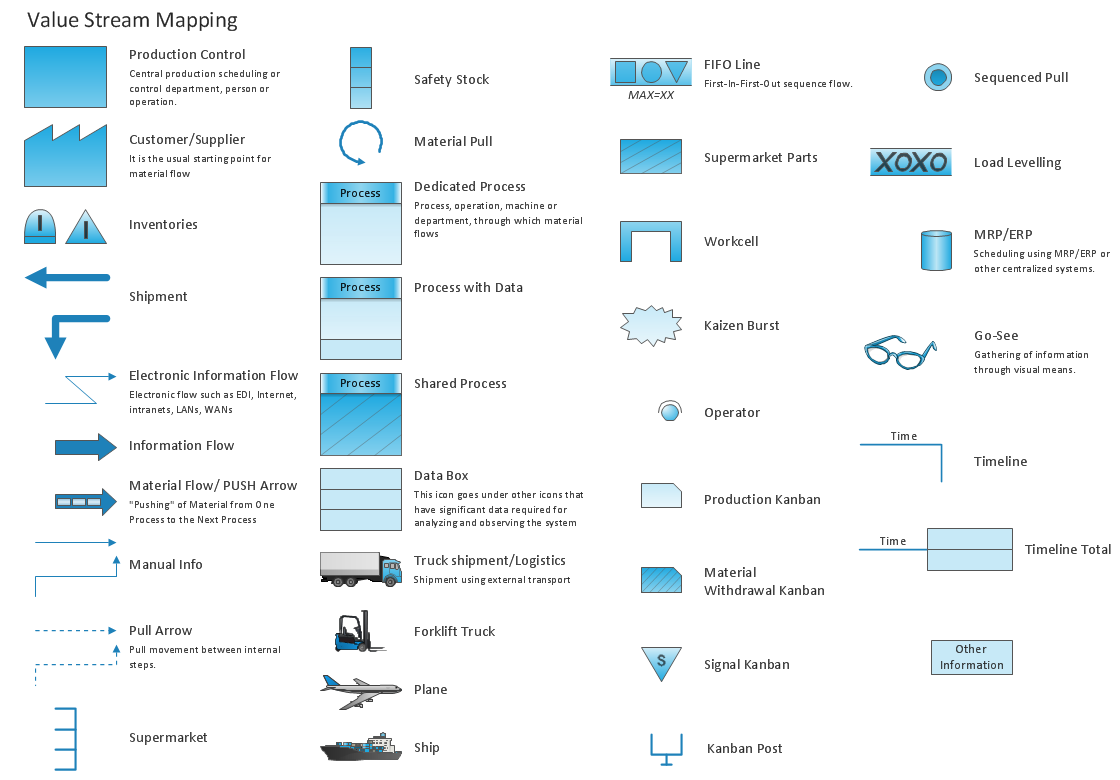

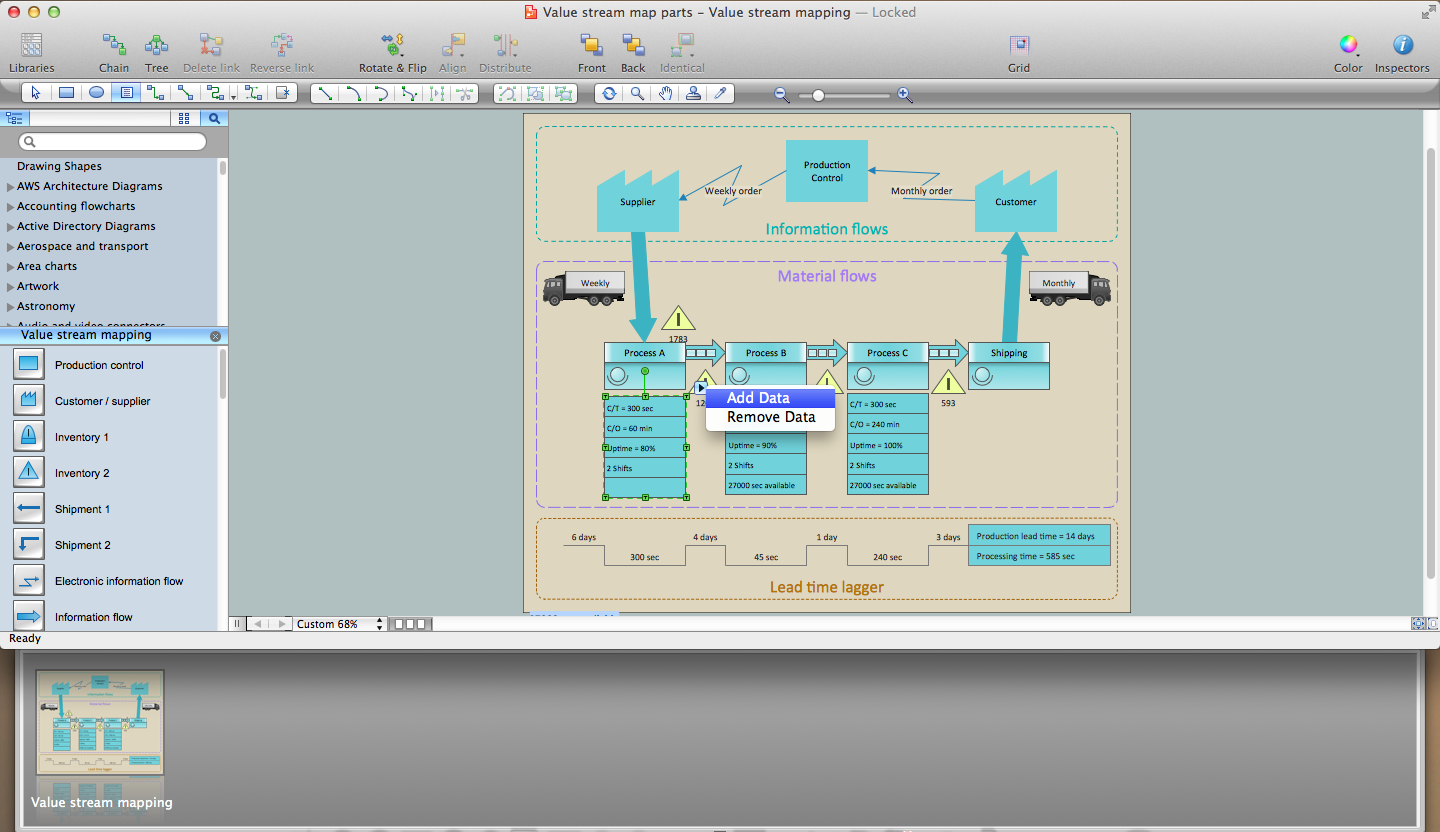

The Value Stream Mapping solution continues to extend the range of ConceptDraw DIAGRAM into a business graphics tool that can be used to document processes of Lean Manufacturing.Value Stream Mapping Template

Use ConceptDraw DIAGRAM extended with Value Stream Mapping solution for document processes with professional designed Value Stream Mapping template.Cause and Effect Diagram

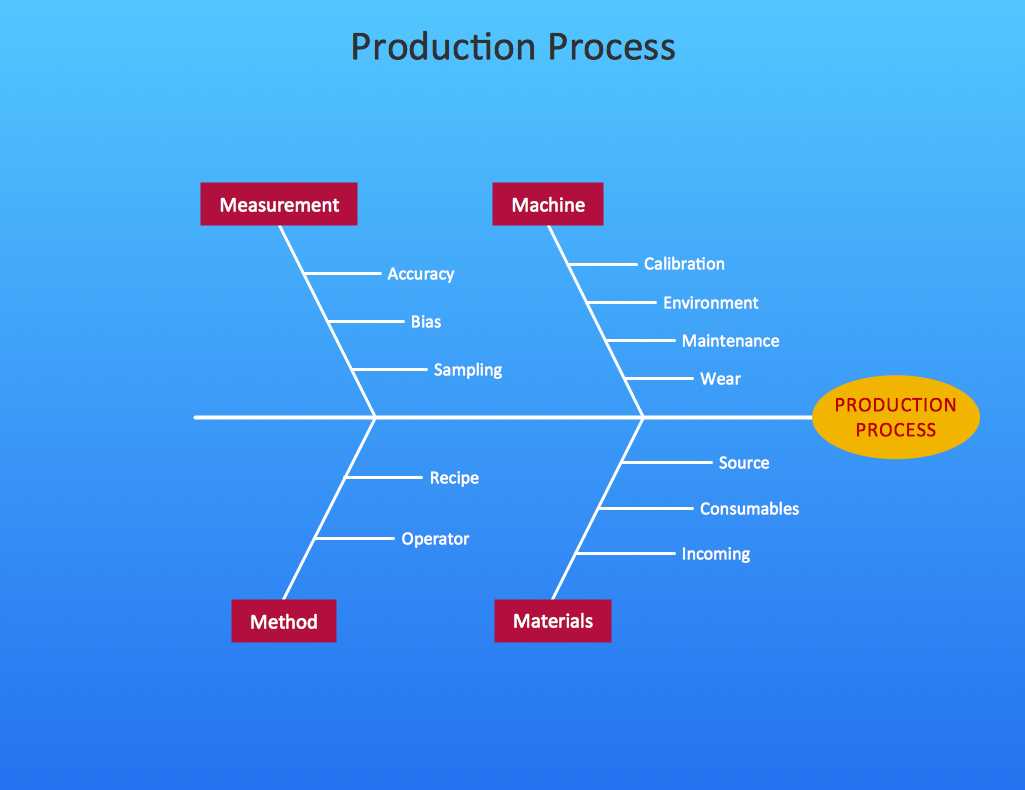

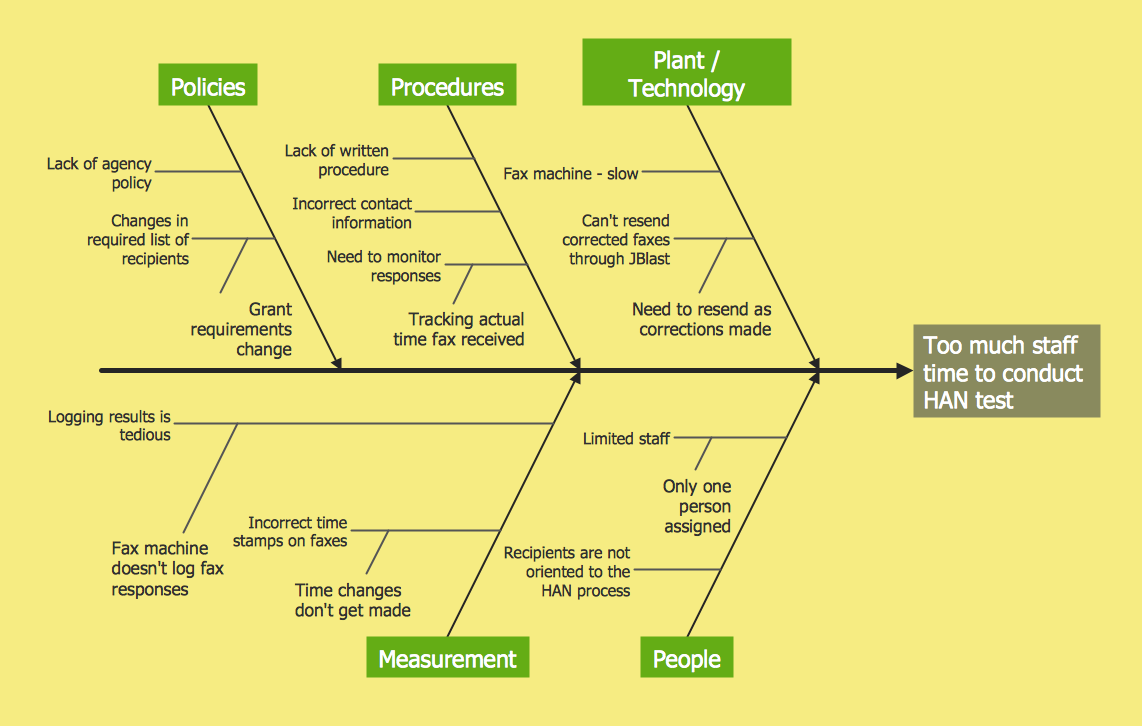

ConceptDraw DIAGRAM software extended with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park is perfect for Cause and Effect Diagram creating. It gives the ability to draw fishbone diagram that identifies many possible causes for an effect or a problem. Causes and Effects are usually grouped into major categories to identify these sources of variation. Causes and Effects in the diagram show relationships among various factor. Fishbone diagram shows factors of Equipment, Process, People, Materials, Environment and Management, all affecting the overall problem.Total Quality Management Value

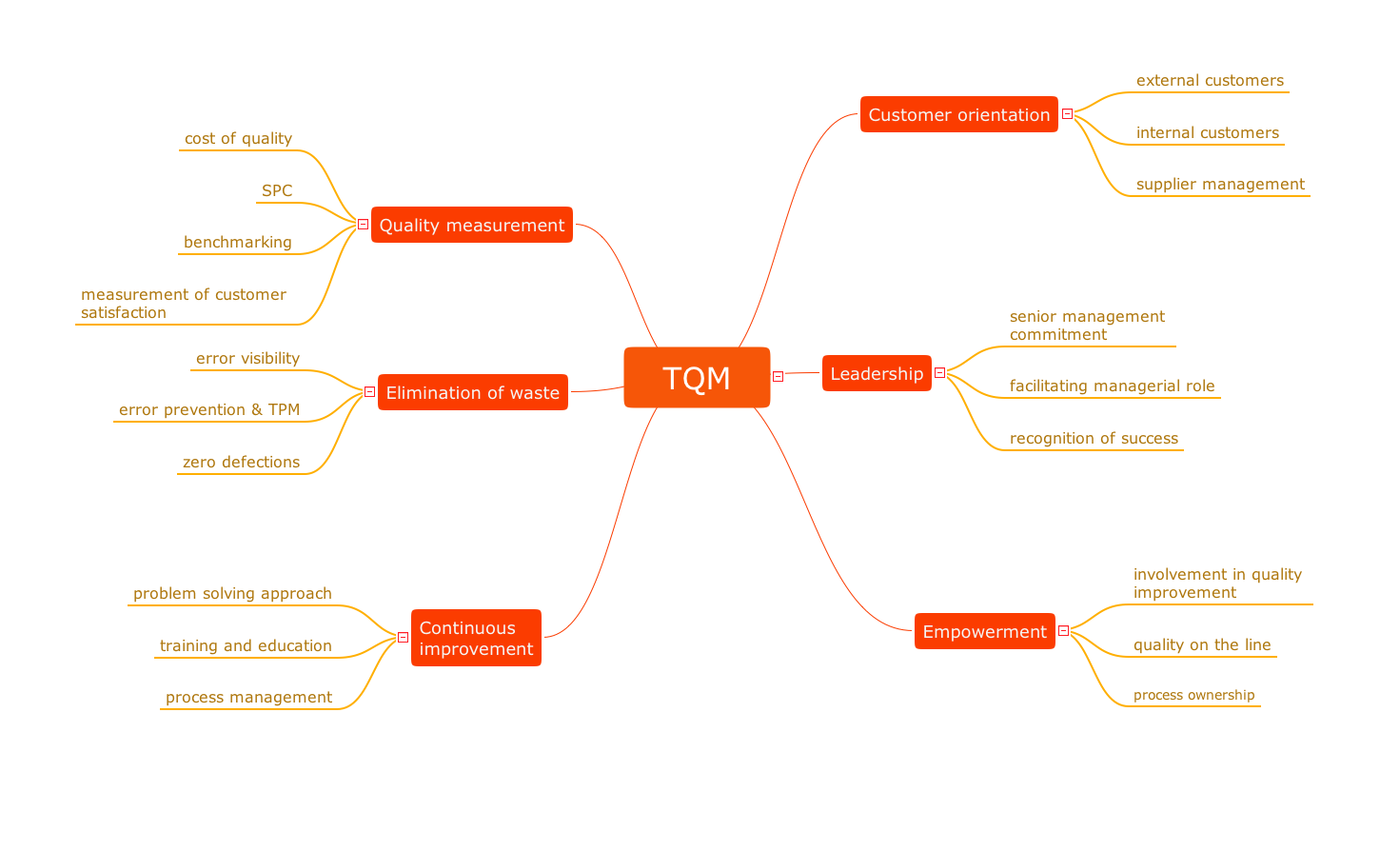

The Total Quality Management Diagram solution helps you and your organization visualize business and industrial processes. Create Total Quality Management diagrams for business process with ConceptDraw software.

Value Stream Mapping

Value Stream Mapping

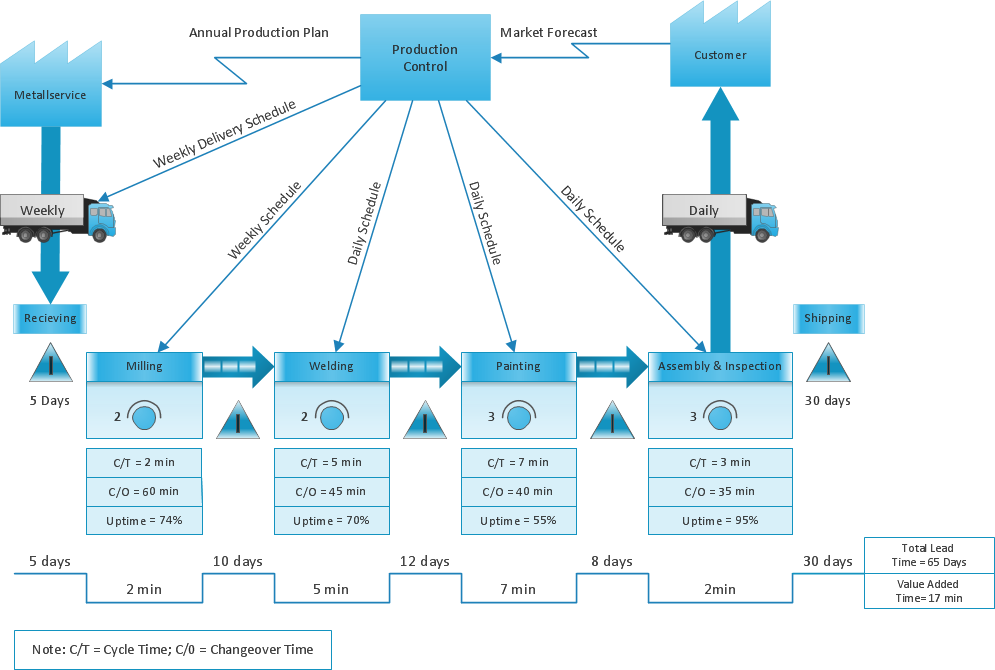

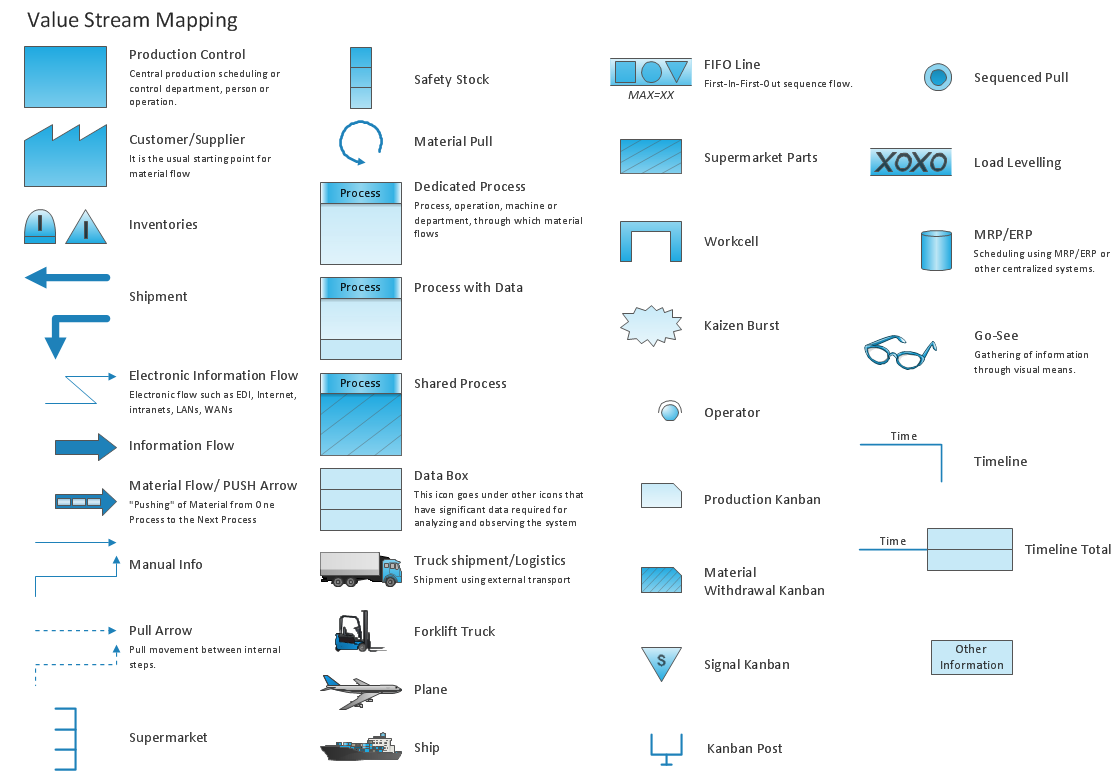

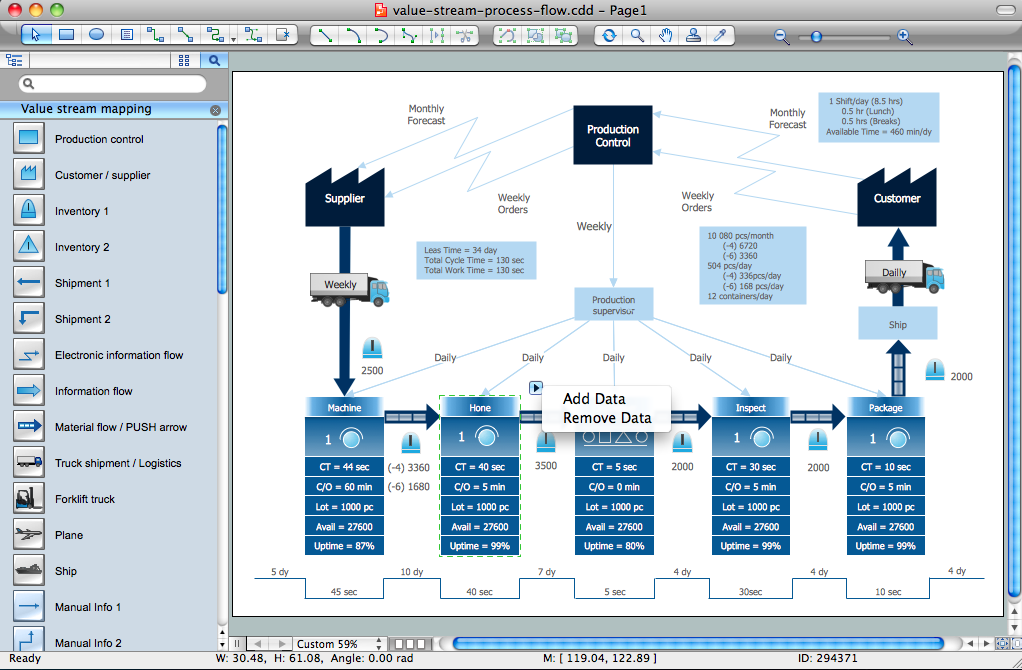

Value stream mapping solution extends ConceptDraw DIAGRAM software with templates, samples and vector stencils for drawing the Value Stream Maps (VSM) in lean manufacturing practice.

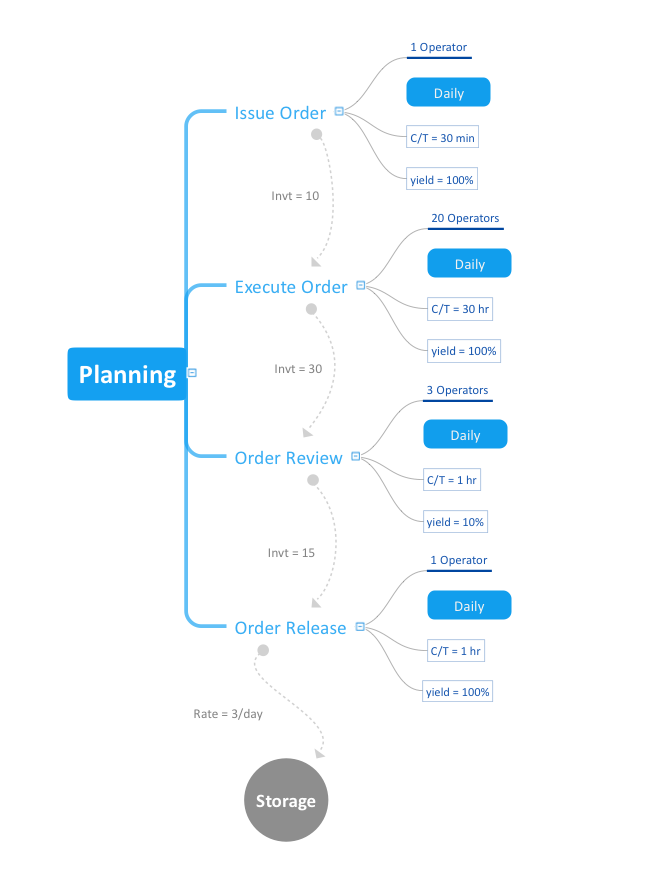

Value Stream Analysis

ConceptDraw Value Stream Maps are used in lean practice for analysis of manufacturing processes to identify the improvement opportunities.Cause and Effect Analysis

When you have some problems you need first to explore the reasons which caused them. Cause and Effect Analysis is a perfect way to do this. ConceptDraw DIAGRAM software enhanced with Fishbone Diagrams solution from the Management area of ConceptDraw Solution Park gives the ability to draw fast and easy Fishbone diagram that identifies many possible causes for an effect.Value Stream Mapping Symbols

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.Quality Mind Map Solution

The Quality Mind Map Solution extends ConceptDraw MINDMAP with the addition of a number of Quality Management Mind Maps (Presentations, Meeting Agendas, and problem-solving techniques).Quality Control

Using mind mapping for quality management is a creative approach that allows one to structure all key quality points on the one page.Lean Six Sigma Diagram Software

Lean Six Sigma (LSS) is a well-known in all over the world methodology of quality improvement and business perfection. ConceptDraw DIAGRAM diagramming and vector drawing software is a powerful Lean Six Sigma Diagram Software thanks to the included Value Stream Mapping solution from the Quality Management Area of ConceptDraw Solution Park.ConceptDraw DIAGRAM Compatibility with MS Visio

For those who are migrating from MS Visio to ConceptDraw DIAGRAM, or for those who have colleagues and clients who use Visio, ConceptDraw DIAGRAM is compatible with MS Visio.VSDX formatted files.VSDX is Visio’s open XML file format, and it can be easily imported and exported by ConceptDraw DIAGRAM.Value Stream & Process Flow Diagramming Software

Value Stream & Process Flow Diagramming Software is a very popular Lean Manufacturing tool that allows to see and visualize in details the company's processes and current state, the flow of material and information, and thus gives the possibility to analyze the efficiency of company's processes and then develop improved processes. Value stream maps are also a good way to define the steps that do not add value to the end product, in other words waste in a company's processes.- Lean Manufacturing Diagrams | How Do Fishbone Diagrams Solve ...

- Value Stream Mapping | Fishbone Diagram | Software Development ...

- Vsm Fish Bone Diagram

- Fishbone Diagram | Value Stream Mapping | Cross-Functional ...

- Cafe and Restaurant Floor Plans | Fishbone Diagrams | Value ...

- Fishbone Diagrams | Process Flowchart | Value-Stream Mapping for ...

- Manufacturing 8 Ms fishbone diagram - Template | Value-Stream ...

- Fault Tree Analysis Diagrams | Value Stream Mapping | Fishbone ...

- How Do Fishbone Diagrams Solve Manufacturing Problems | Value ...

- Value Stream Mapping | Fishbone Diagram | Crystal Mapping | Swot ...

- Fishbone Diagrams | Logistics Flow Charts | Value Stream Mapping ...

- Process Flowchart | Fishbone Diagram | Value Stream Mapping ...

- Fishbone Diagram | Presentation Exchange | Entity-Relationship ...

- Quality Control | Value-Stream Mapping for Manufacturing | Best ...

- SWOT and TOWS Matrix Diagrams | Fishbone Diagram ...

- Total Quality Management Value | Fishbone Diagram | 4ms Of ...

- Lean Manufacturing Diagrams | Manufacturing 8 Ms fishbone ...

- Enterprise Architecture Diagrams | Manufacturing 8 Ms fishbone ...

- How Do Fishbone Diagrams Solve Manufacturing Problems ...

- Fishbone Diagram | Using Fishbone Diagrams for Problem Solving ...

- ERD | Entity Relationship Diagrams, ERD Software for Mac and Win

- Flowchart | Basic Flowchart Symbols and Meaning

- Flowchart | Flowchart Design - Symbols, Shapes, Stencils and Icons

- Flowchart | Flow Chart Symbols

- Electrical | Electrical Drawing - Wiring and Circuits Schematics

- Flowchart | Common Flowchart Symbols

- Flowchart | Common Flowchart Symbols