Value-Stream Mapping for Manufacturing

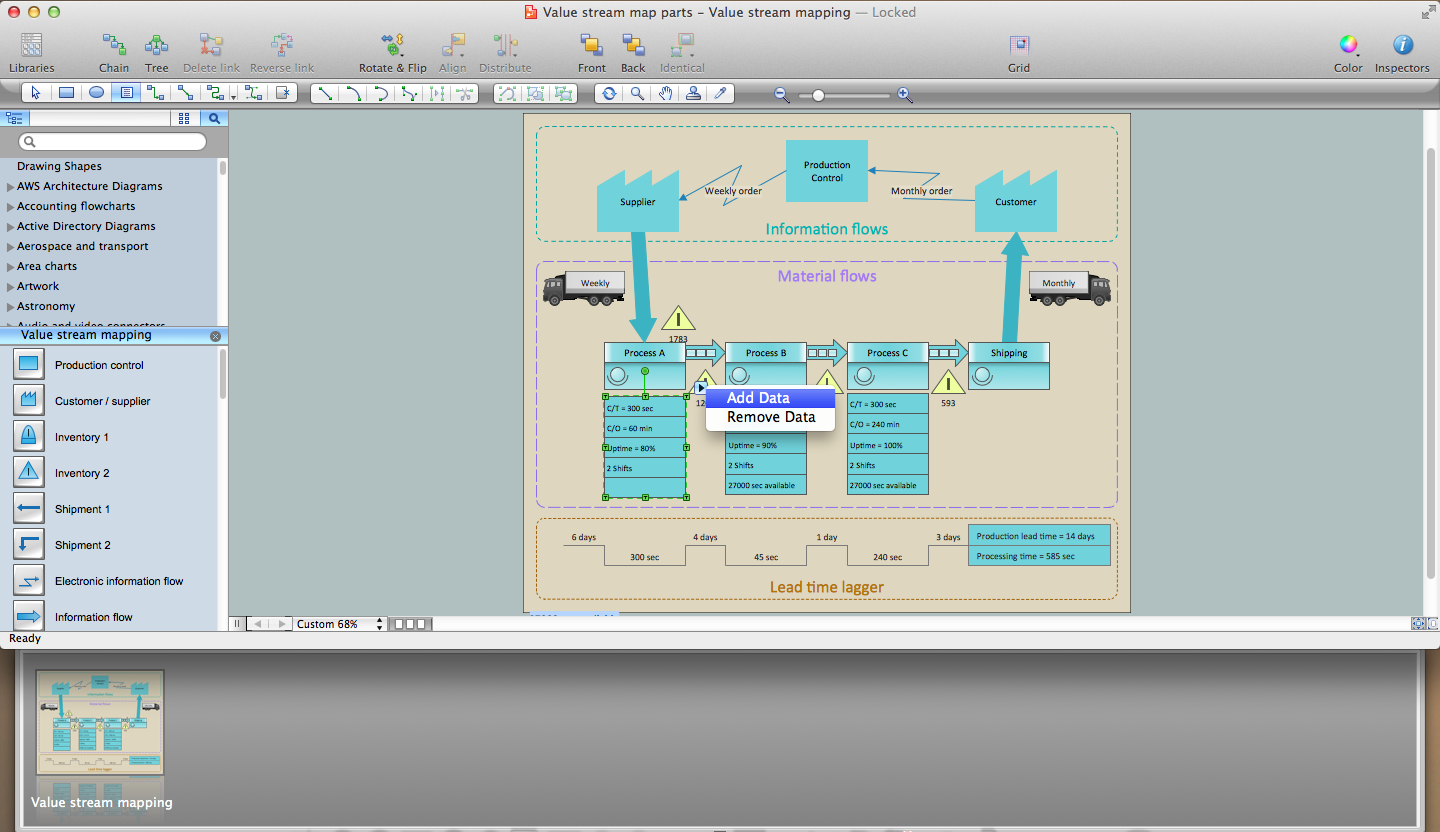

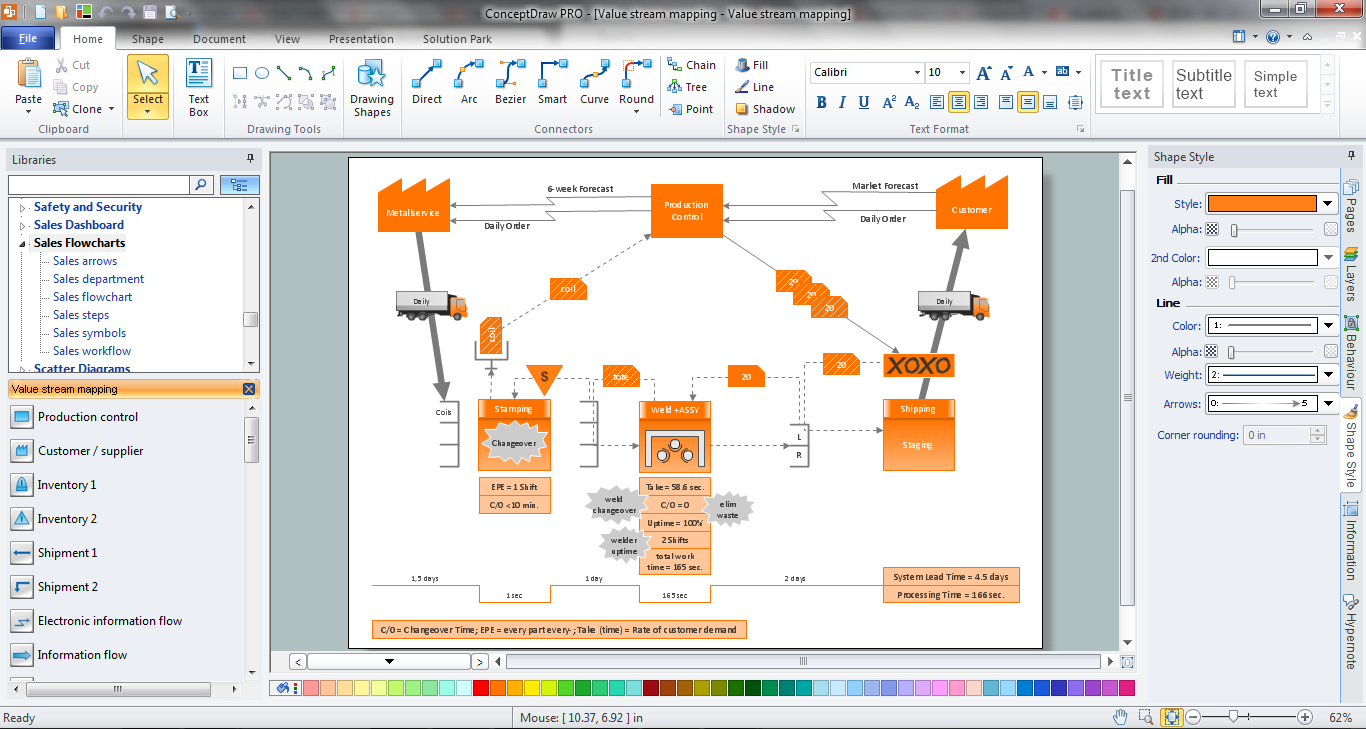

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Lean Six Sigma Diagram Software

Lean Six Sigma (LSS) is a well-known in all over the world methodology of quality improvement and business perfection. ConceptDraw PRO diagramming and vector drawing software is a powerful Lean Six Sigma Diagram Software thanks to the included Value Stream Mapping solution from the Quality Management Area of ConceptDraw Solution Park.Lean Value Stream Map

Lean Manufacturing tool is a new Value Stream Mapping solution found in the ConceptDraw Solution Park.The Lean Enterprise Value Stream Mapping

Create value stream maps - for value stream analysis and value stream management, material and information flow mapping, using our quick start templates included with ConceptDraw.Value Stream Mapping and Analysis

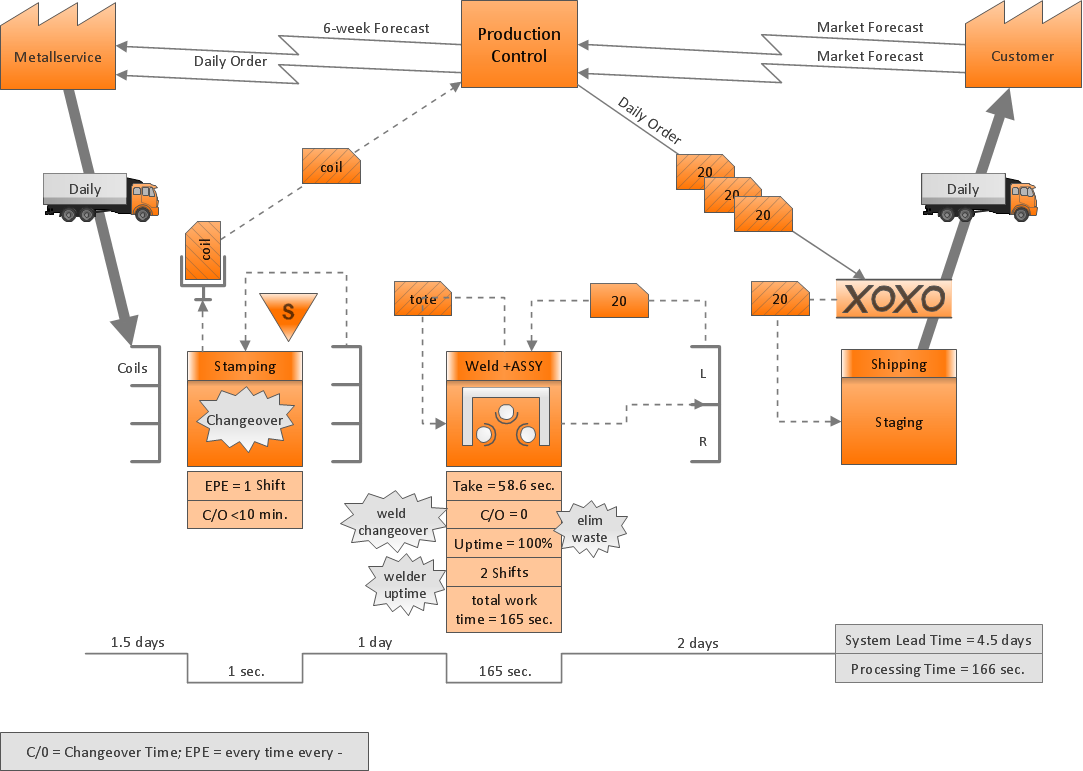

Value Stream Maps are used in lean methodology for analysis of manufacturing process and identification of the improvement opportunities.Mind Mapping in the Quality Management

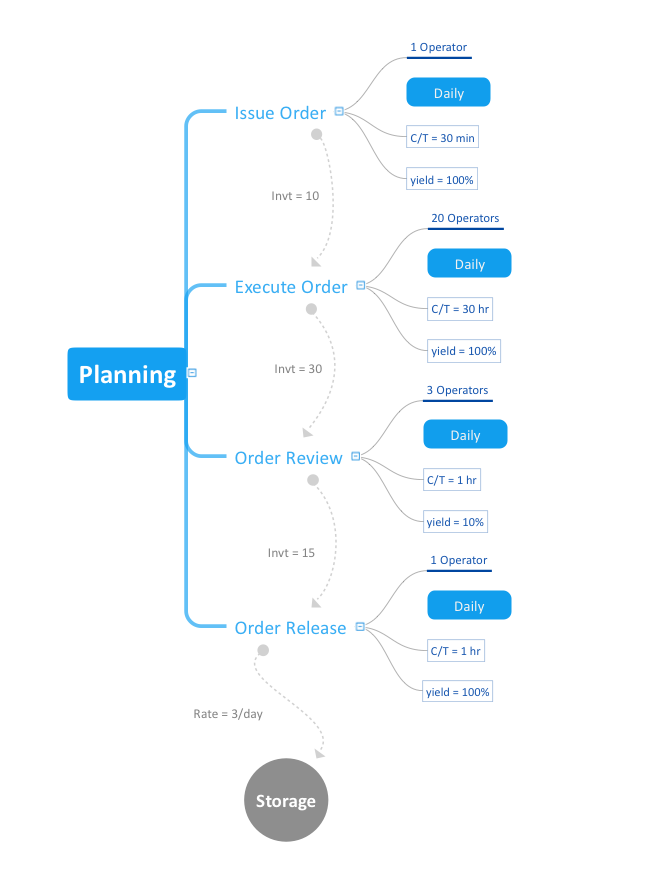

ConceptDraw MINDMAP has a addition to the ConceptDraw Solution Park that provides a creative approach to visualizing quality processes, Quality Mind Map Solution.Purposes of a Value Stream Management Tool

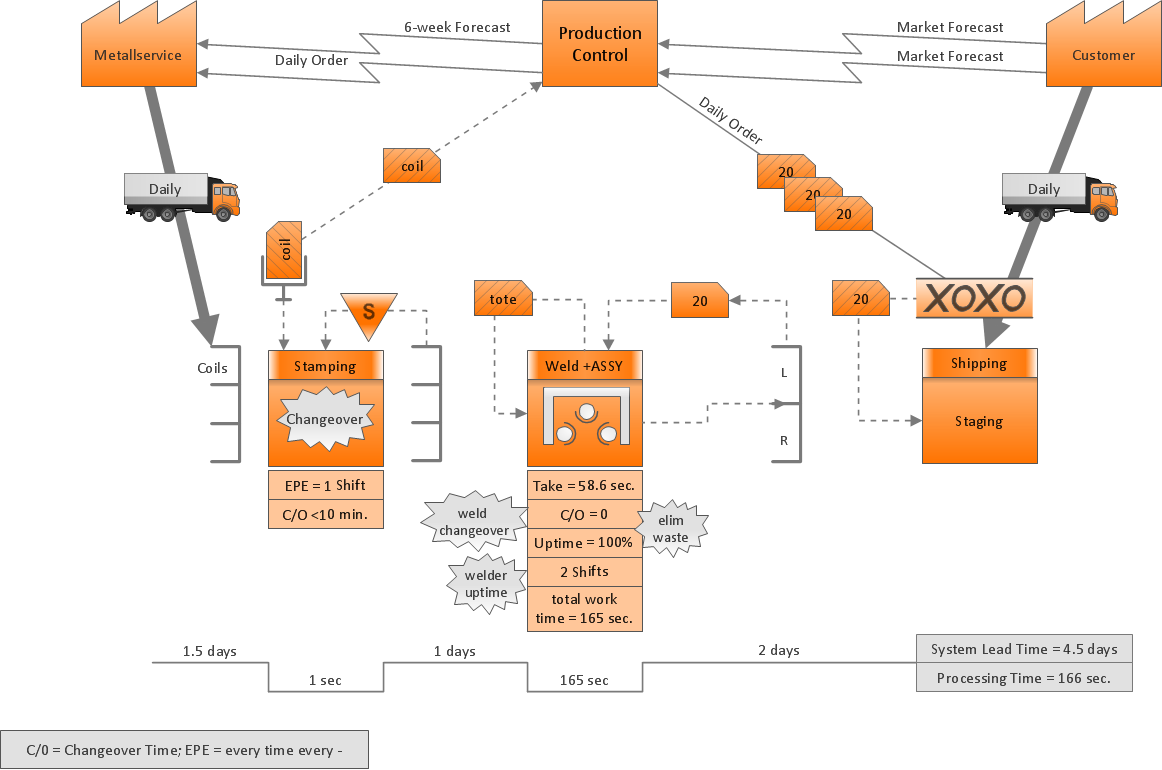

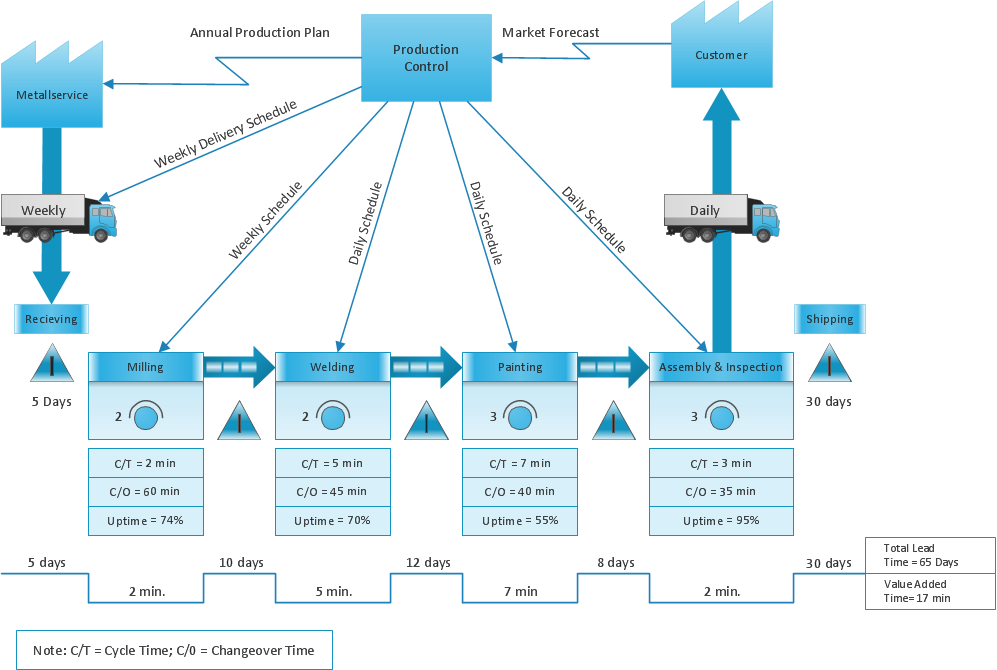

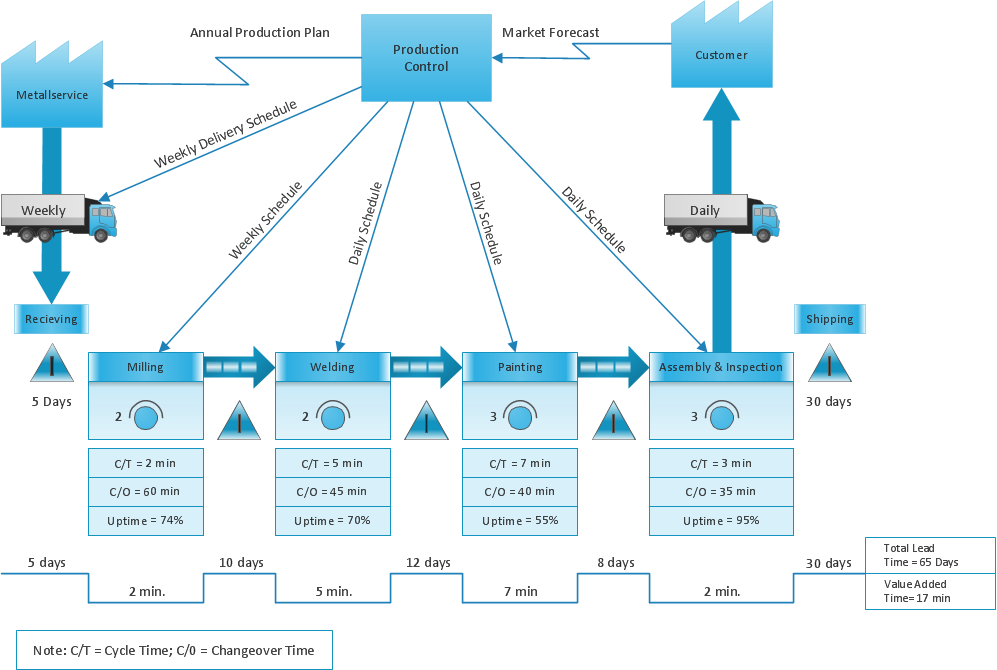

ConceptDraw Value Stream Maps visualize for a manufacturing plant the material and information flow required to deliver a product/service to customers.Value Stream Mapping

Use ConceptDraw Value Stream Maps (VSM) visualization for a manufacturing plant the material and information flow required to deliver a product/service to customers. The new Value Stream Mapping solution found in the ConceptDraw Solution Park continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes in any organization.Quality Mind Map Solution

The Quality Mind Map Solution extends ConceptDraw MINDMAP with the addition of a number of Quality Management Mind Maps (Presentations, Meeting Agendas, and problem-solving techniques).Value Stream Mapping Icons

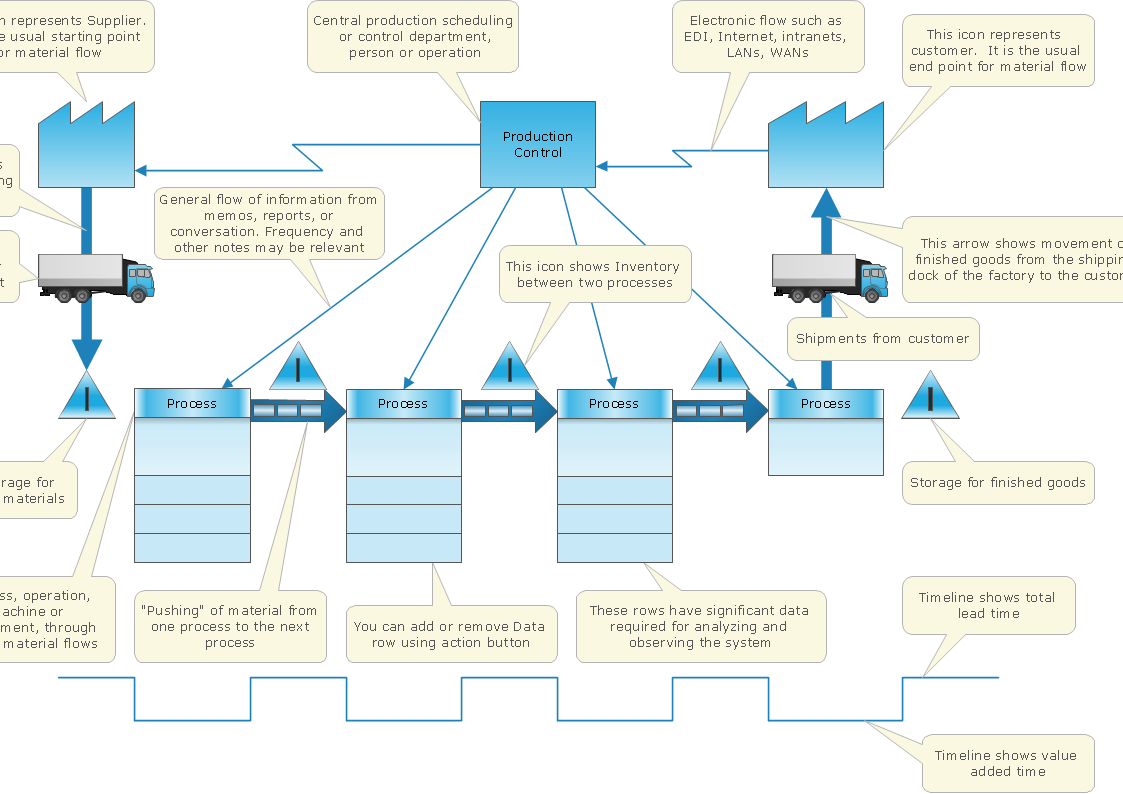

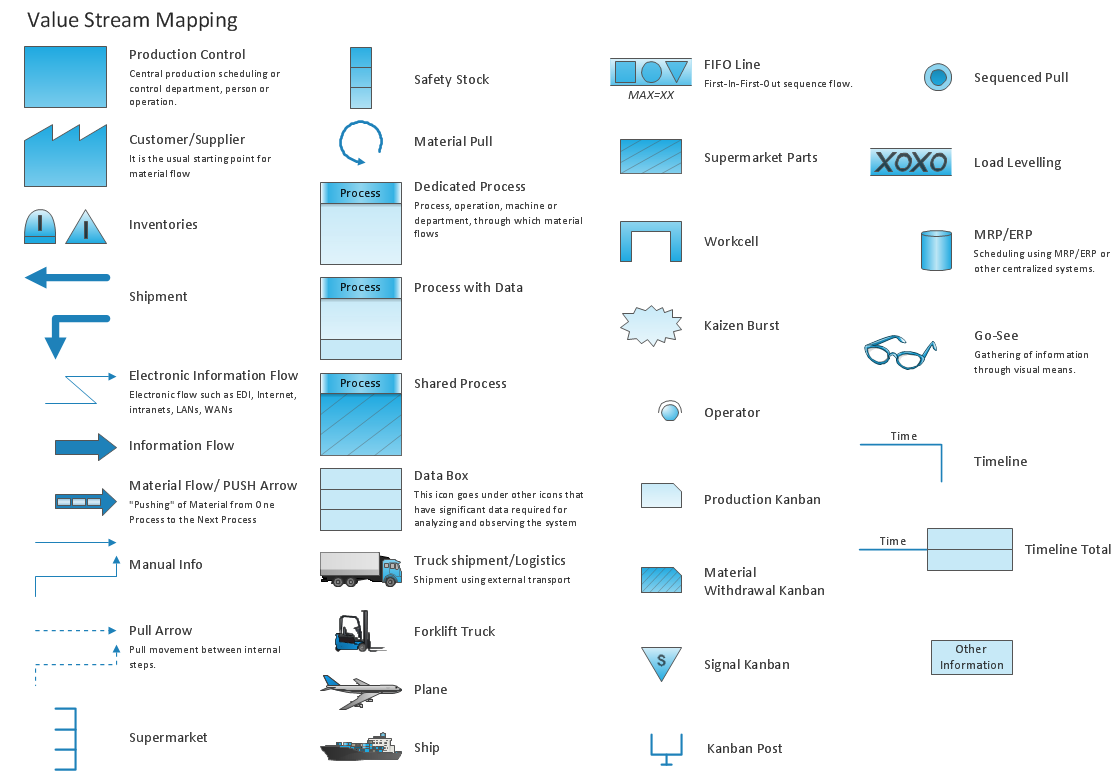

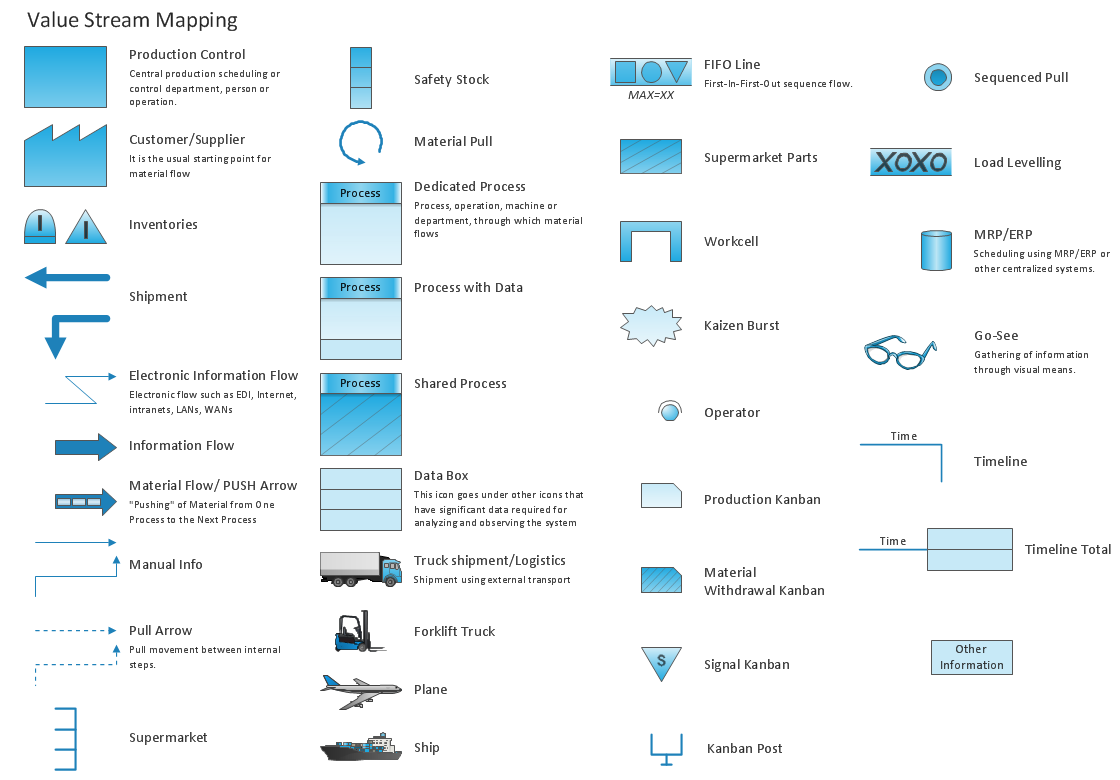

The library with 40 vector stencils is included in the ConceptDraw Value Stream Mapping solution.

Value Stream Mapping

Value Stream Mapping

Value stream mapping solution extends ConceptDraw PRO software with templates, samples and vector stencils for drawing the Value Stream Maps (VSM) in lean manufacturing practice.

Lean Manufacturing Diagrams

The Value Stream Mapping solution continues to extend the range of ConceptDraw PRO into a business graphics tool that can be used to document processes of Lean Manufacturing.Types of Flowcharts

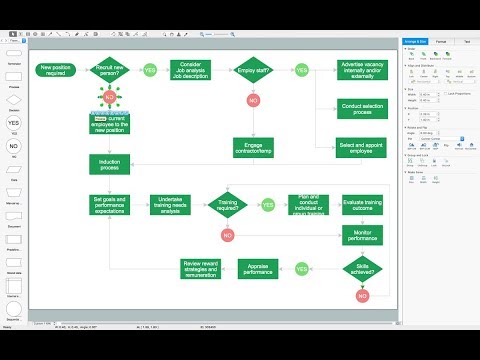

A Flowchart is a graphically representation of the process, algorithm or the step-by-step solution of the problem. There are ten types of Flowcharts. Using the Flowcharts solution from the Diagrams area of ConceptDraw Solution Park you can easy and quickly design the Flowchart of any of these types.

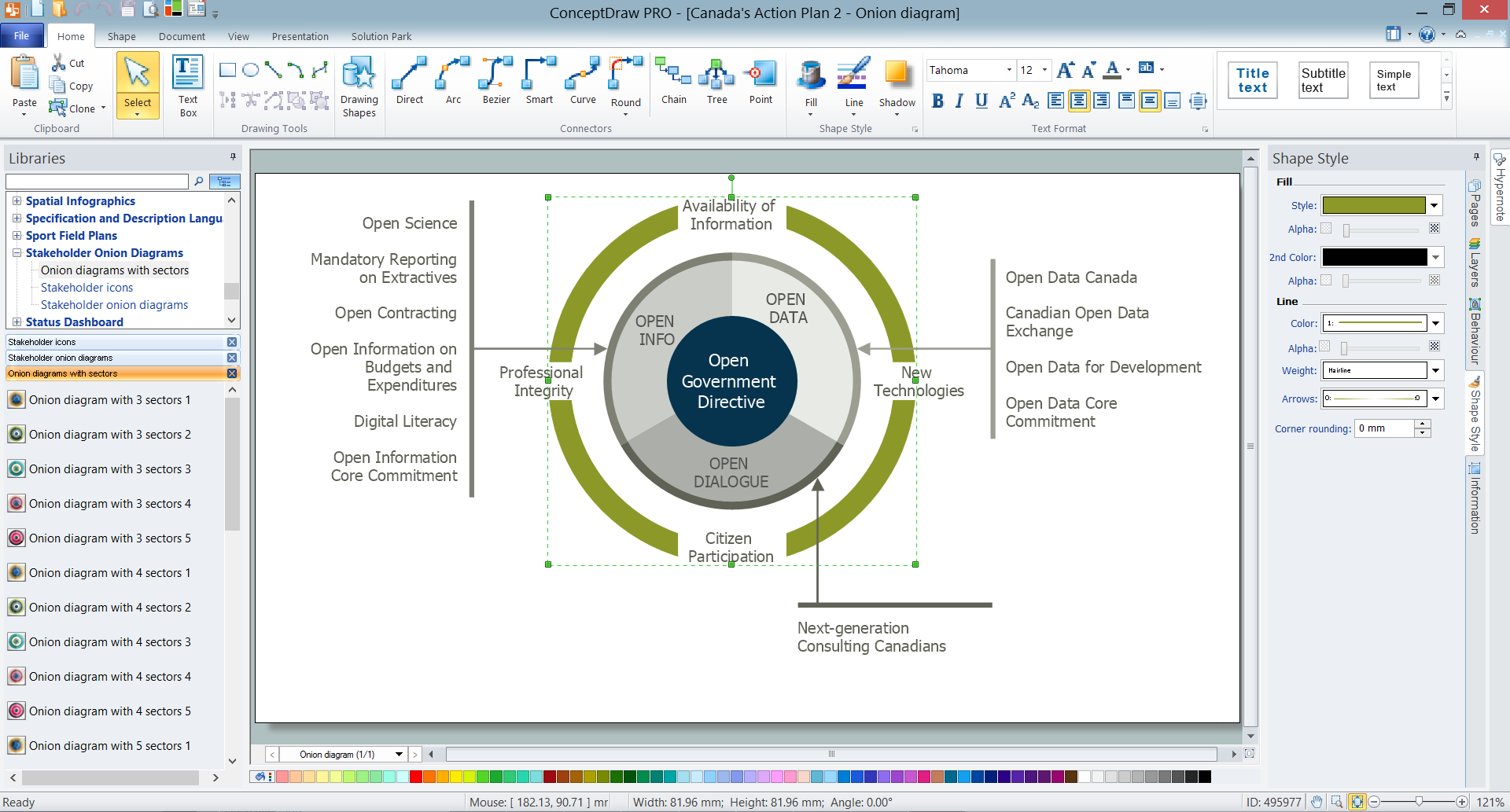

How To Create Onion Diagram

An onion diagram is a kind of chart that shows the dependencies among parts of an organization or process. The chart displays items in concentric circles, where the items in each ring depend on the items in the smaller rings. The Onion Diagram is able to show layers of a complete system in a few circles.But how to create Onion Diagram? Now, it's very easy thanks to the ConceptDraw PRO diagramming and vector drawing software extended with Stakeholder Onion Diagrams Solution from the Management Area of ConceptDraw Solution Park.

Value Stream Mapping Symbols

VSM symbols are the best for a production process designing. The entire Value Stream Mapping method uses a graphical representation of the manufacturing process, factors' pros and cons, that all stakeholders can easily understand. Value Stream Mapping is a graphical technique that provides possibilities to improve analysis of a manufacturing process, at the stage of the transferring information or materials that required to deliver a product or service to the customer.- Manufacturing 8 Ms fishbone diagram - Template | Business ...

- Lean Manufacturing Diagrams | Lean Six Sigma Diagram Software ...

- Lean Manufacturing Diagrams | Value Stream Mapping for the Lean ...

- Lean Value Stream Map

- Methodology Diagram Template

- Value Stream Mapping for the Lean Office

- Learn how to create a current state value stream map | Lean Value ...

- Best Value Stream Mapping mac Software

- Value Stream Mapping Methodology

- Lean Manufacturing Diagrams | Best Value Stream Mapping mac ...

- Value Stream Mapping for the Lean Office | Lean Manufacturing ...

- Value Stream Mapping for the Lean Office | Value stream with ...

- Lean Mapping

- Value Stream Mapping | Lean Manufacturing Diagrams | Quality ...

- Value Stream Mapping

- Value-Stream Mapping for Manufacturing | Lean Manufacturing ...

- The Lean Enterprise Value Stream Mapping | Lean Manufacturing ...

- Lean Value Stream Map | Lean Manufacturing Diagrams | Value ...

- Learn how to create a current state value stream map | Value Stream ...

- Value Stream Mapping Template

- ERD | Entity Relationship Diagrams, ERD Software for Mac and Win

- Flowchart | Basic Flowchart Symbols and Meaning

- Flowchart | Flowchart Design - Symbols, Shapes, Stencils and Icons

- Flowchart | Flow Chart Symbols

- Electrical | Electrical Drawing - Wiring and Circuits Schematics

- Flowchart | Common Flowchart Symbols

- Flowchart | Common Flowchart Symbols